Method for preparing super absorbent resin containing fulvic acid sodium and MS dry medium

A technology of superabsorbent resin and sodium fulvate, which is applied in the fields of botanical equipment and methods, gardening methods, gardening tools/equipment, etc., can solve the problems of limiting the application of MS medium, fast water volatilization rate, etc., to reduce watering frequency, improve the absorption efficiency, and be beneficial to the effect of industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

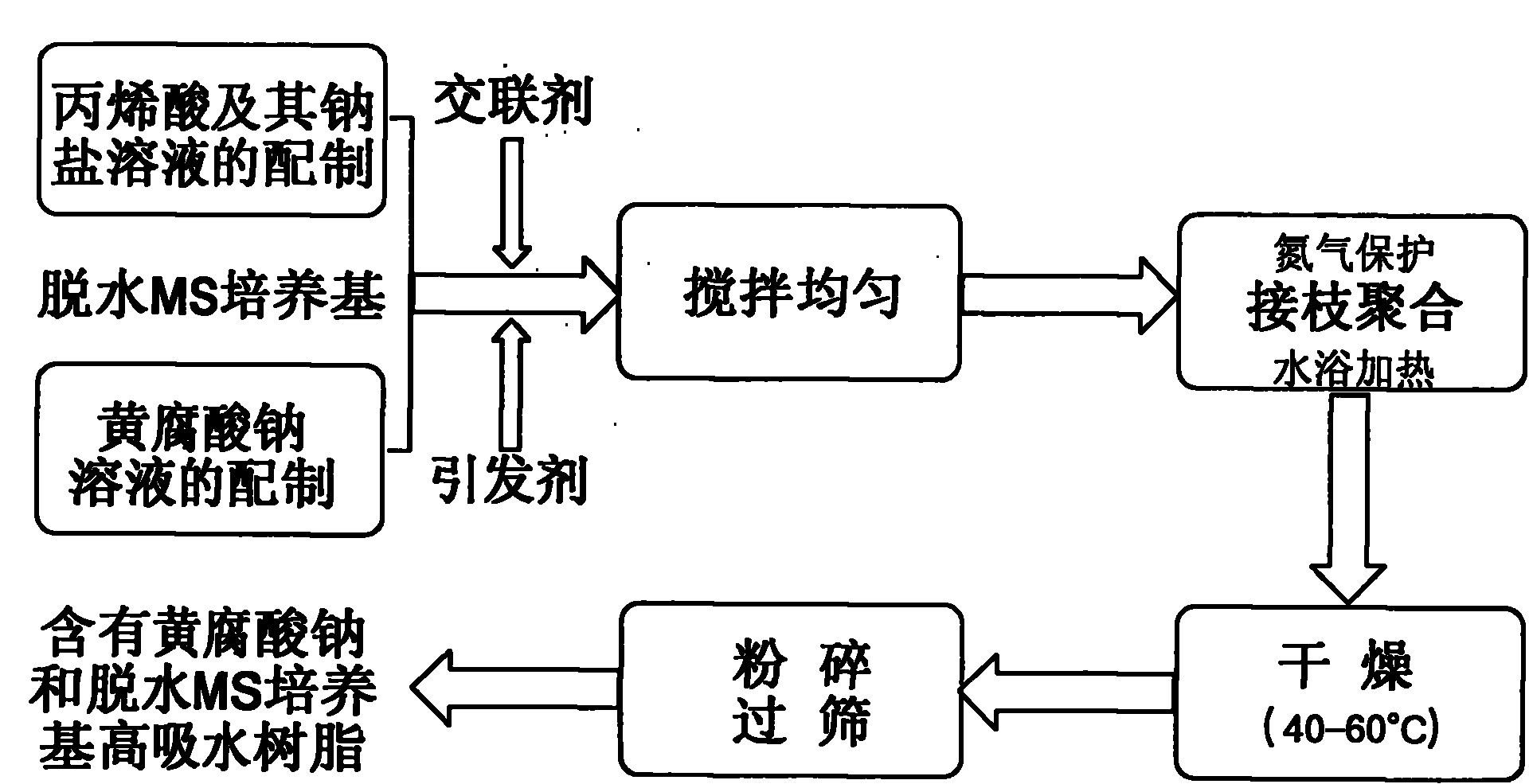

Method used

Image

Examples

Embodiment 1

[0016] Example 1: Dissolve 6.0g of sodium hydroxide with 19ml of deionized water, and neutralize 27g (25.6ml) of acrylic acid under cooling and stirring in an ice-water bath; dissolve 0.01g of sodium fulvic acid with 25ml of deionized water, and then add neutralization Good acrylic acid and its sodium salt solution, 10g of dehydrated MS medium, 100mg of potassium persulfate, 6ml of N,N'-methylenebisacrylamide solution with a concentration of 5mg / ml, stirred at room temperature for 1.0h, and then passed nitrogen gas And start to heat slowly, make it react at 60-80°C for 1 hour, continue to heat up, keep warm in a boiling water bath for 1.5 hours, stop nitrogen flow, cool to room temperature, take out the product, dry, crush, and sieve to obtain The superabsorbent resin containing sodium fulvic acid and dehydrated MS medium, the water absorption of the product obtained in this example is 725 times.

Embodiment 2

[0017] Embodiment 2: The experimental conditions are the same as in Embodiment 1, except that 0.05 g of sodium fulvic acid is dissolved in 25 ml of deionized water, and the water absorption ratio of the product obtained in this embodiment is 530 times.

Embodiment 3

[0018] Embodiment 3: The experimental conditions are the same as in Embodiment 1, except that 0.1 g of sodium fulvic acid is dissolved in 25 ml of deionized water, and the water absorption ratio of the product obtained in this embodiment is 760 times.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com