Mesoporous 4A zeolum and preparation method thereof

A technology of zeolite and zeolite crystal, which is applied in the field of mesoporous 4A zeolite and its preparation, can solve the problems of hindering diffusion, reducing batch yield, and increasing storage volume, and achieves simple preparation process, moderate crystal size, and improved use. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

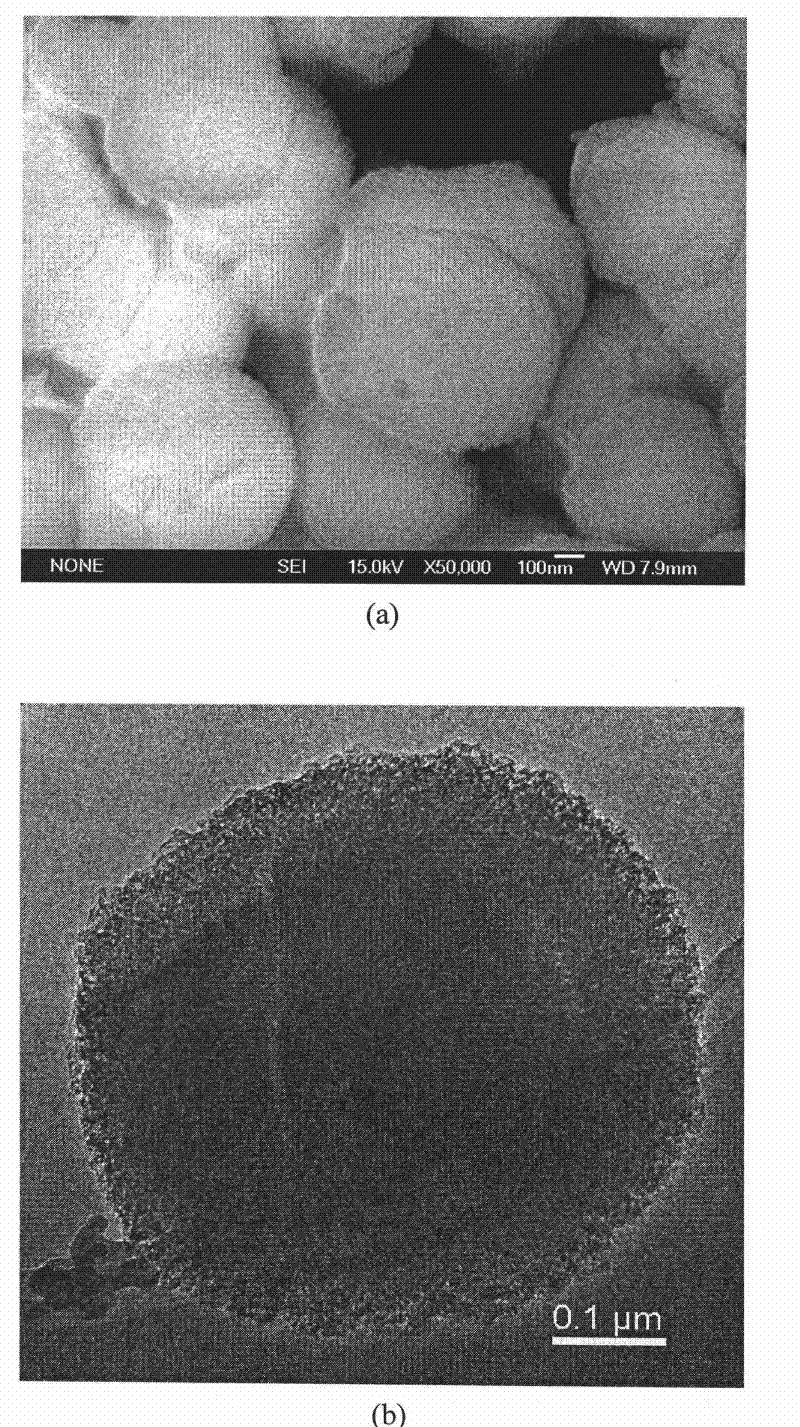

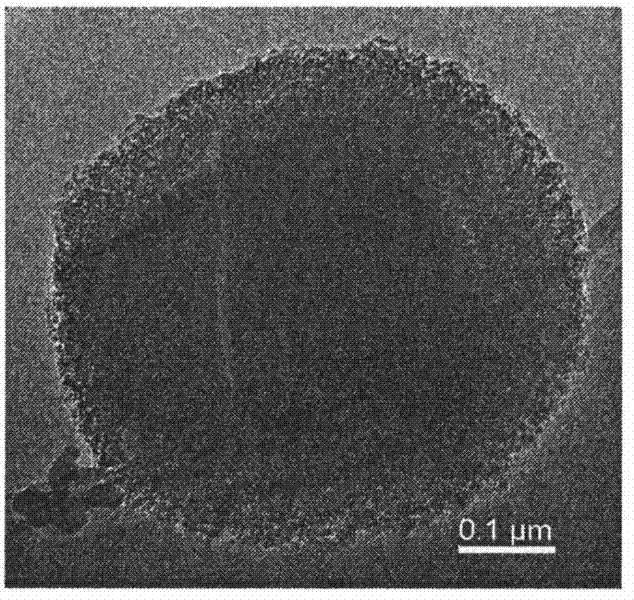

Image

Examples

Embodiment approach 1

[0022] (1) Dissolve 0.1mol of anilinopropyltrimethoxysilane in 670mL of alcoholic aqueous solution containing 60% (w / w) of methanol, and add 30g (0.5mol) after the dissolution is complete, with a specific surface area of 200m 2 / g, silicon dioxide with a particle size of 12nm, poured into a 1500mL three-necked flask, refluxed and stirred at 100°C for 8h, separated from solid and liquid, washed with ethanol at room temperature, and dried at 100°C to obtain a solid surface silanized silica powder.

[0023] (2) Take 1.86 g of the above-mentioned silanized silica, add 32 mL of NaOH solution with a concentration of 1.8 mol / L and 4.3 mL of sodium metaaluminate solution (wherein Al 2 o 3 The content of 2.52mol / L, OH - content of 11.77mol / L), stirred at room temperature for 3 hours to obtain silica-alumina gel; put it into a reaction kettle, and crystallize at 90°C for 20h; centrifuge the crystallized product from solid and liquid, wash at room temperature, dry at 100°C, and dry at...

Embodiment approach 2

[0027]Change the amount of anilinopropyltrimethoxysilane in step (1) of Embodiment 1 to 0.0625mol, and keep other conditions unchanged, carry out silanization to silicon dioxide; then take 1.67g of silanized silicon dioxide, and then follow the steps (2) Synthesis of mesoporous 4A zeolite. N 2 The mesopore specific surface area measured by adsorption is 193m 2 / g, mesopore volume 0.15mL / g. For calcium ion exchange, the measured t 50 and t 100 2 minutes and 30 minutes, respectively; for magnesium ion exchange, the measured t 50 and t 100 8 minutes and 90 minutes respectively.

Embodiment approach 3

[0029] Change the amount of anilinopropyl trimethoxysilane in embodiment 1 step (1) to 0.025mol, and keep other conditions constant, carry out silanization to silicon dioxide; 1.44g of silicon was used to synthesize mesoporous 4A zeolite. N 2 The mesopore specific surface area measured by adsorption is 115m 2 / g, mesopore volume 0.08mL / g. For calcium ion exchange, the measured t 50 and t 100 5 minutes and 60 minutes, respectively; for magnesium ion exchange, the measured t 50 and t 100 30 minutes and 180 minutes respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com