Etching method and substrate having conductive polymer

A conductive polymer and etching technology, which is applied to the conductive layer, circuit, and electrical components on the insulating carrier, can solve the problems that it is difficult to make ink, and the conductive polymer is easy to condense, so as to achieve the effect of stable etching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

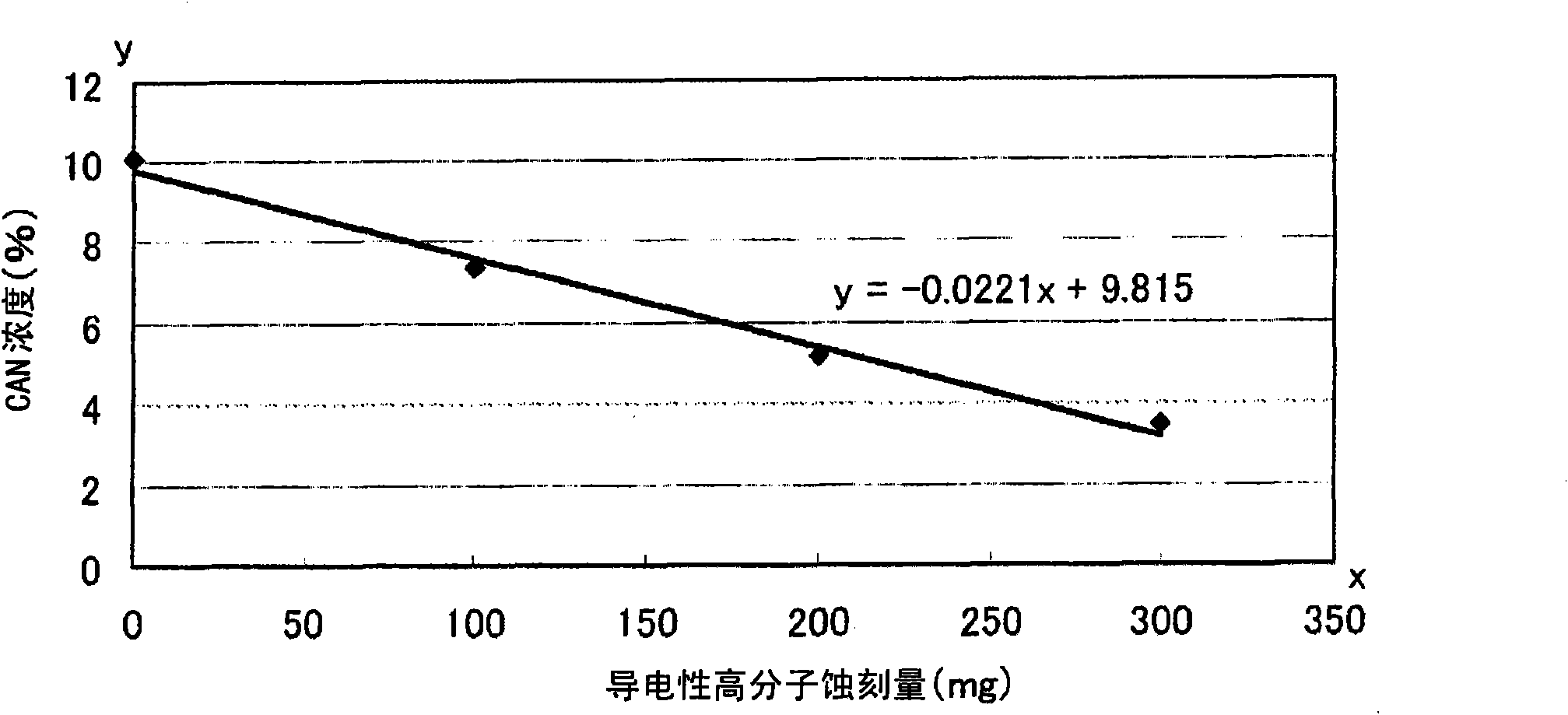

[0159] In the water, add a specified amount of ammonium cerium nitrate (NH 4 ) 2 Ce(NO 3 ) 6 (Hereafter also referred to as "CAN".) and concentrated nitric acid to prepare etching solution 1.

[0160] In addition, a polythiophene-based conductive polymer (Baytron PH 500 manufactured by H.C. Starck Co., Ltd.) was placed on the surface of a 2.5×5 cm square polyethylene terephthalate (PET) sheet so that the weight of the conductive polymer Film formation was performed at 100 mg, and the member thus produced was subjected to an etching test.

[0161] The conductive polymer test piece formed into a film was immersed in 100 g of this etching solution, stirred at room temperature for 27 hours, and dissolved.

[0162] Next, the CAN concentration was determined by a titration method (redox titration method) using potassium iodide. The results are shown in Table 4 and figure 2 .

[0163] As a result, it was confirmed that the CAN concentration decreased as the etching amount of ...

Embodiment 2

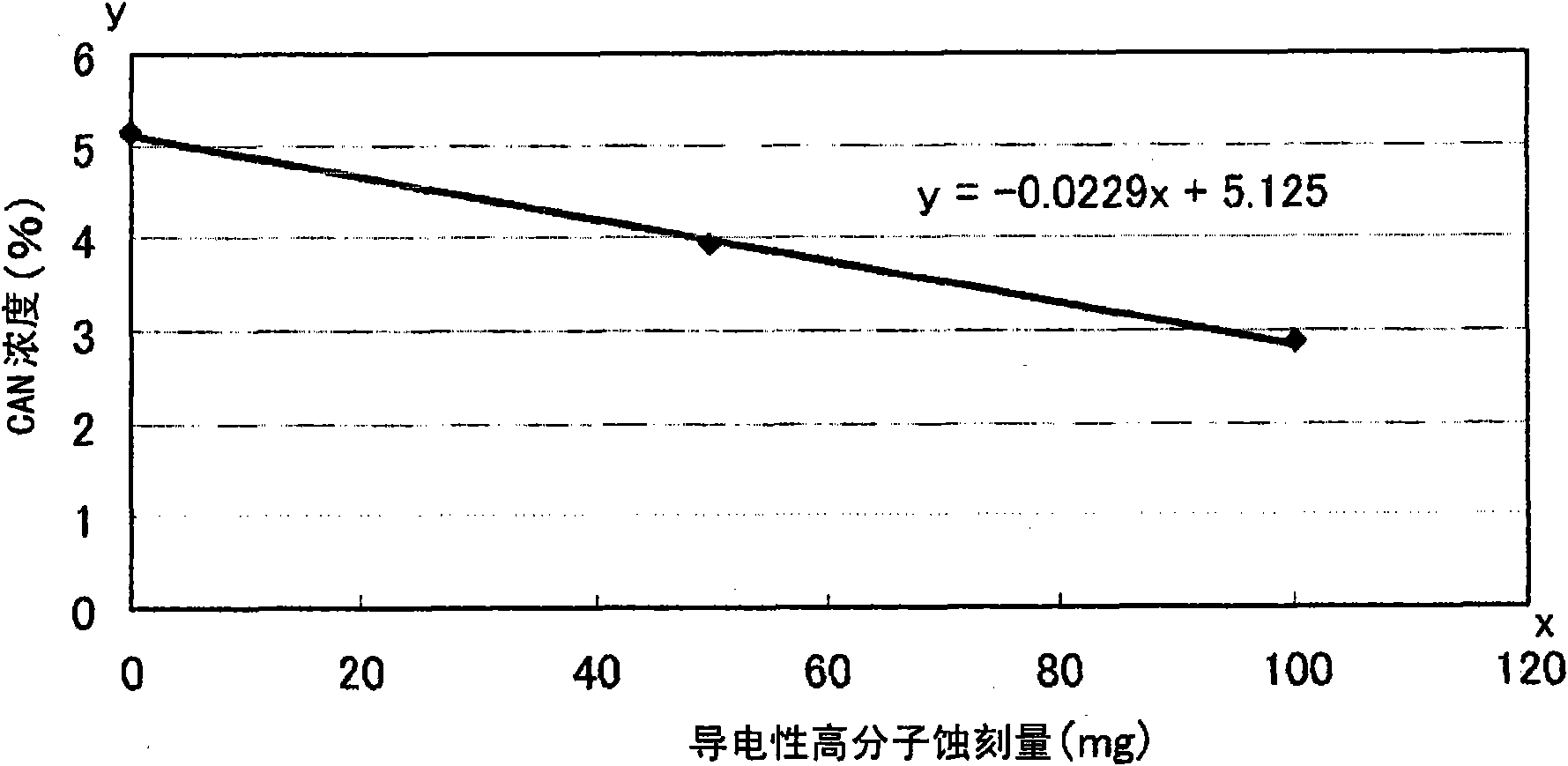

[0170] In the same manner as in Example 1, etchant 2 shown in Table 3 was prepared. In addition, a polythiophene-based conductive polymer (Baytron PH 500 manufactured by H.C. Starck Co., Ltd.) was similarly formed on the surface of a 2.5×5 cm square PET sheet so that the weight of the conductive polymer was 50 mg. The components thus fabricated were used for etching tests. The conductive polymer was dissolved in the same manner as in Example 1.

[0171] Next, the CAN concentration was determined by a titration method (redox titration method) using potassium iodide. The results are shown in Table 5 and image 3 .

[0172] As a result, it was confirmed that even if the concentration of CAN and the concentration of nitric acid were changed, the concentration of CAN decreased as the amount of conductive polymer added increased.

[0173] [table 5]

[0174]

Embodiment 3

[0176] The conductive polymer test piece was immersed in 100 g each of etching solutions 1 and 2, and stirred at room temperature for 27 hours to dissolve. Next, the oxidation-reduction potential (ORP) was measured, and the results are shown in Table 6.

[0177] As a result, it was confirmed that ORP decreased as the amount of conductive polymer added increased. From this, it can be seen that the etchant can be managed according to the ORP.

[0178] [Table 6]

[0179]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com