Method for controlling Pichia pastoris to ferment to produce antibacterial peptide by utilizing dissolved oxygen parameters

A production method and parameter control technology, applied in the field of bioengineering, can solve the problems of no antibacterial peptide LL-37 genetically engineered yeast fermentation production method, etc., and achieve the effects of shortened antibacterial activity, simple preparation process, and reduced cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

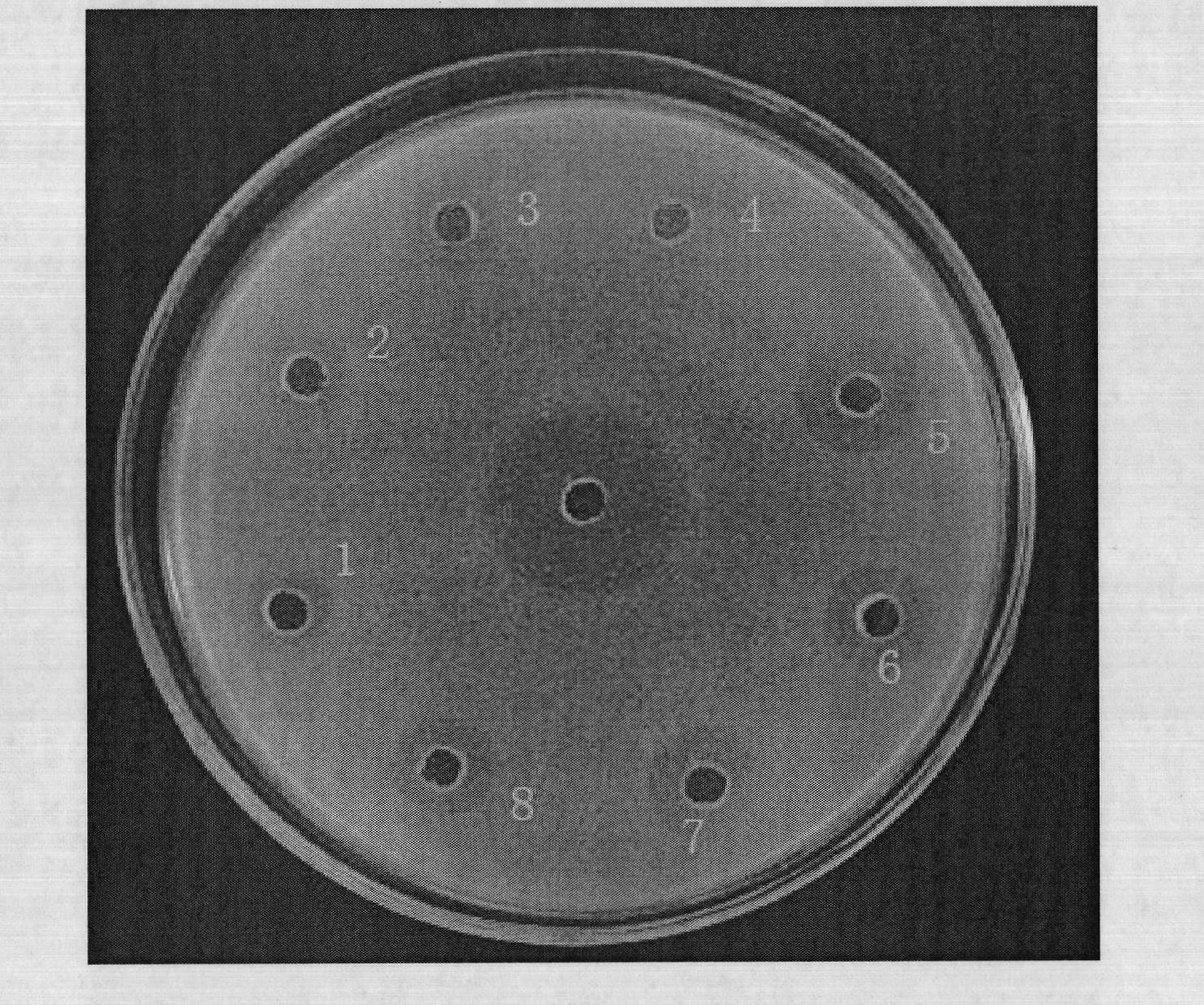

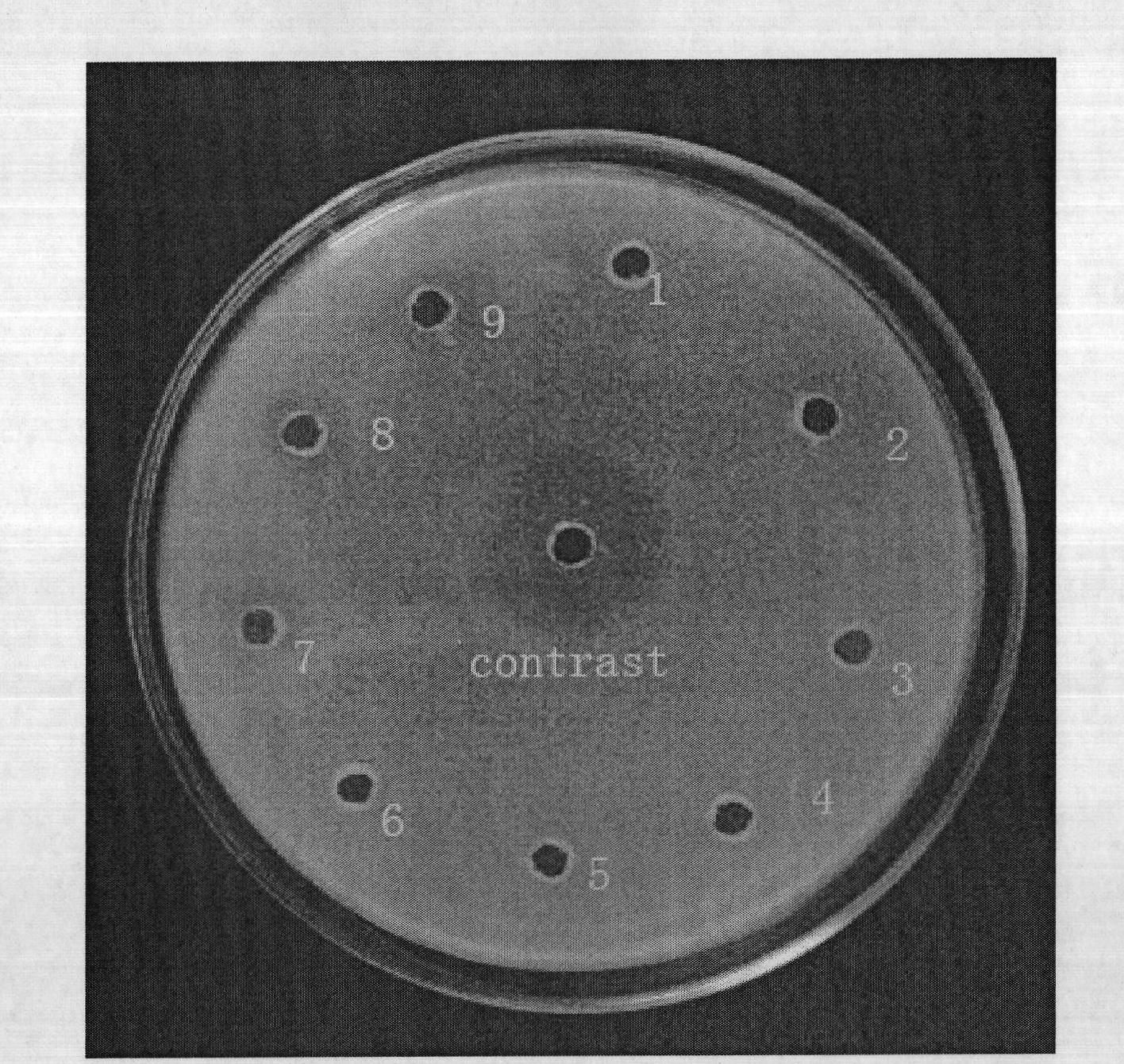

Image

Examples

Embodiment Construction

[0010] Technical scheme of the present invention is as follows:

[0011] A method for producing antimicrobial peptides by using dissolved oxygen parameters to control Pichia pastoris fermentation, characterized in that the steps are as follows:

[0012] (1) Add the culture medium into the fermenter, and after cooling it down, adjust the fermentation temperature to 27-30°C, calibrate the dissolved oxygen (DO ) to obtain the fermentation medium;

[0013] (2) Inoculate the activated gene yeast strain in the fermentation medium, the inoculation amount is 10% (v / v), mark it as 0 point at the same time, start fermentation, the fermentation conditions are: ventilation is 0.3~1.5vvm, stirring The speed is 100~400rpm, the tank pressure is 0.02~0.1MPa;

[0014] (3) When the DO value rises from less than 10% to more than 50%, start feeding methanol until the DO value falls back to 10% to 30%, stop feeding methanol, and when the DO value rises steadily to more than 50% again, Start fee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com