Method for removing hydrogen sulfide from industrial gas in recycling way

An industrial gas, hydrogen sulfide technology, applied in chemical instruments and methods, separation methods, manganese sulfate and other directions, can solve the problems of large heat consumption and sulfuric acid, waste of resource utilization, etc., to achieve high utilization rate of manganese, less secondary pollution, Effects with low taste requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

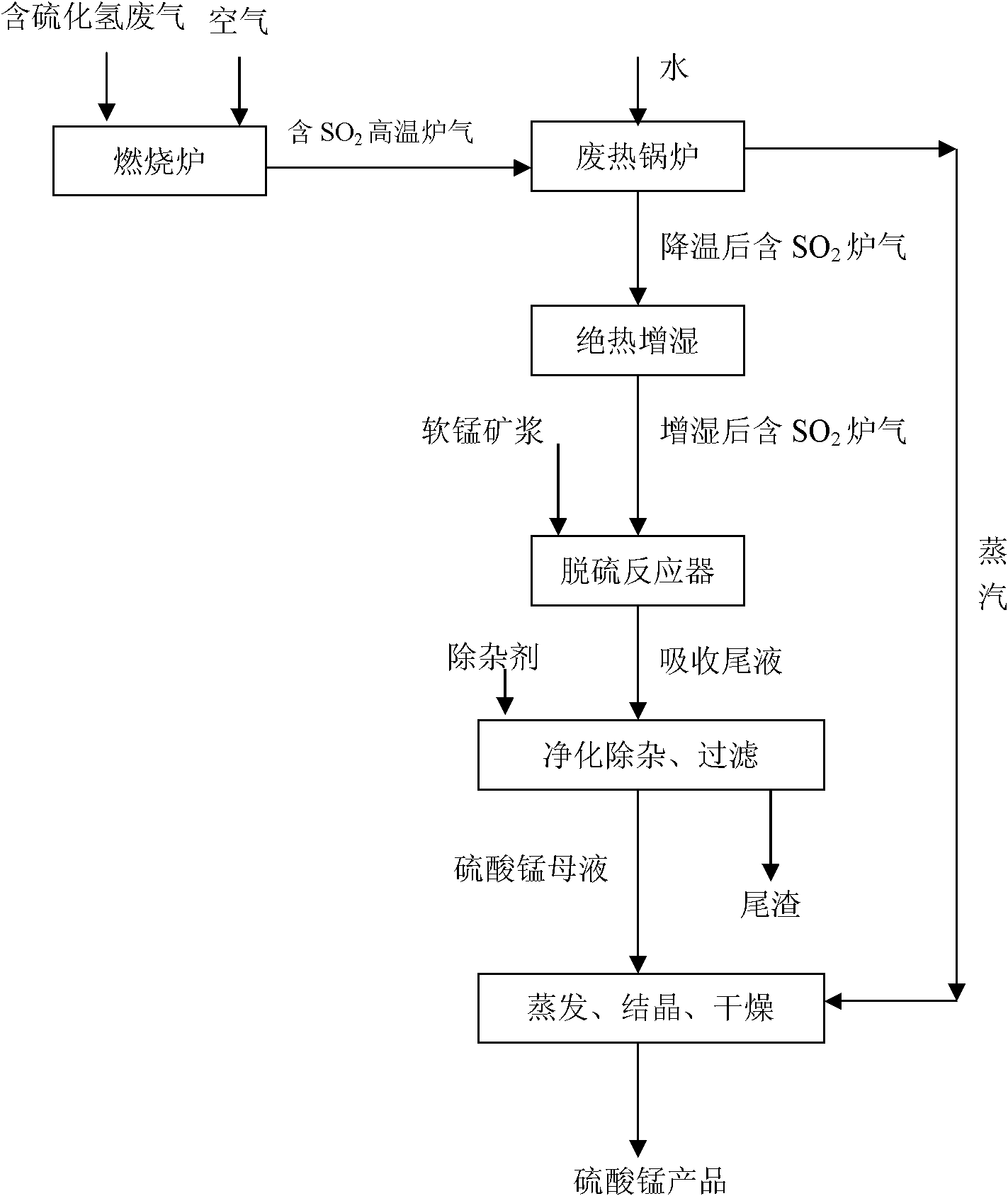

[0032] The waste gas treated in this embodiment is hydrogen sulfide-containing waste gas from coking chemical industry, and the amount of waste gas to be treated is 6000Nm 3 / h, the main composition of exhaust gas is: H 2 S 30%, CO 2 65%, N 2 4%. The technological process of this embodiment is as attached figure 2 shown. First, the pyrolusite powder and water are prepared in the slurry tank equipped with agitator to make a slurry with a liquid-solid ratio (mass ratio) of 3:1, and the slurry is pumped into the desulfurization reactor from the inlet by the slurry pump. Start the main blower set at the rear end of the combustion furnace, so that the combustion furnace is in a negative pressure state, including H 2 The exhaust gas and air of S are sucked into the combustion furnace by negative pressure through the pipeline to burn together, and the combustion temperature is controlled at about 1000°C. Combustion produces SO 2 The high-temperature furnace gas enters the w...

Embodiment 2

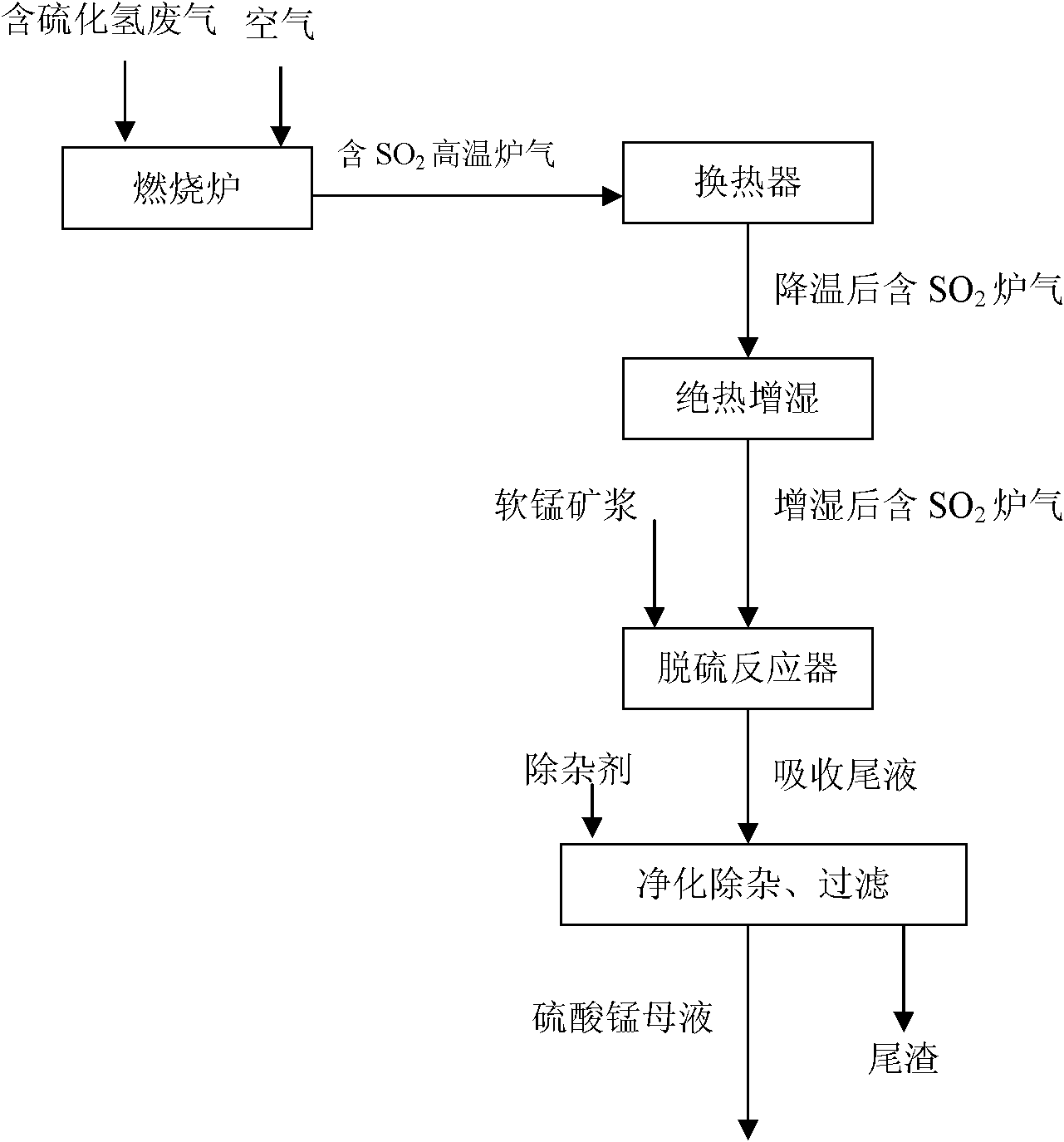

[0034] The waste gas treated in this embodiment is hydrogen sulfide-containing waste gas from coking chemical industry, and the amount of waste gas to be treated is 6000Nm 3 / h, the main composition of exhaust gas is: H 2 S 30%, CO 2 65%, N 2 4%. The technological process of this embodiment is as attached figure 1 shown. First, the pyrolusite powder and water are prepared in a slurry tank equipped with a stirrer to make a slurry with a liquid-solid ratio (mass ratio) of 5:1, and the slurry is driven into the desulfurization reactor from the inlet by a slurry pump. Start the main blower set at the rear end of the combustion furnace, so that the combustion furnace is in a negative pressure state, including H 2 The exhaust gas and air of S are sucked into the combustion furnace by negative pressure through the pipeline to burn together, and the combustion temperature is controlled at about 700°C. Combustion produces SO 2 The high-temperature furnace gas enters the heat e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com