Single-power driven double-generator set using electric injection system

A generator set and single-power technology, applied in the direction of electric components, charging systems, engine components, etc., can solve the problems of small generator sets that have not been applied, and achieve the effects of avoiding end vibration, avoiding wind resistance, and reducing size Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

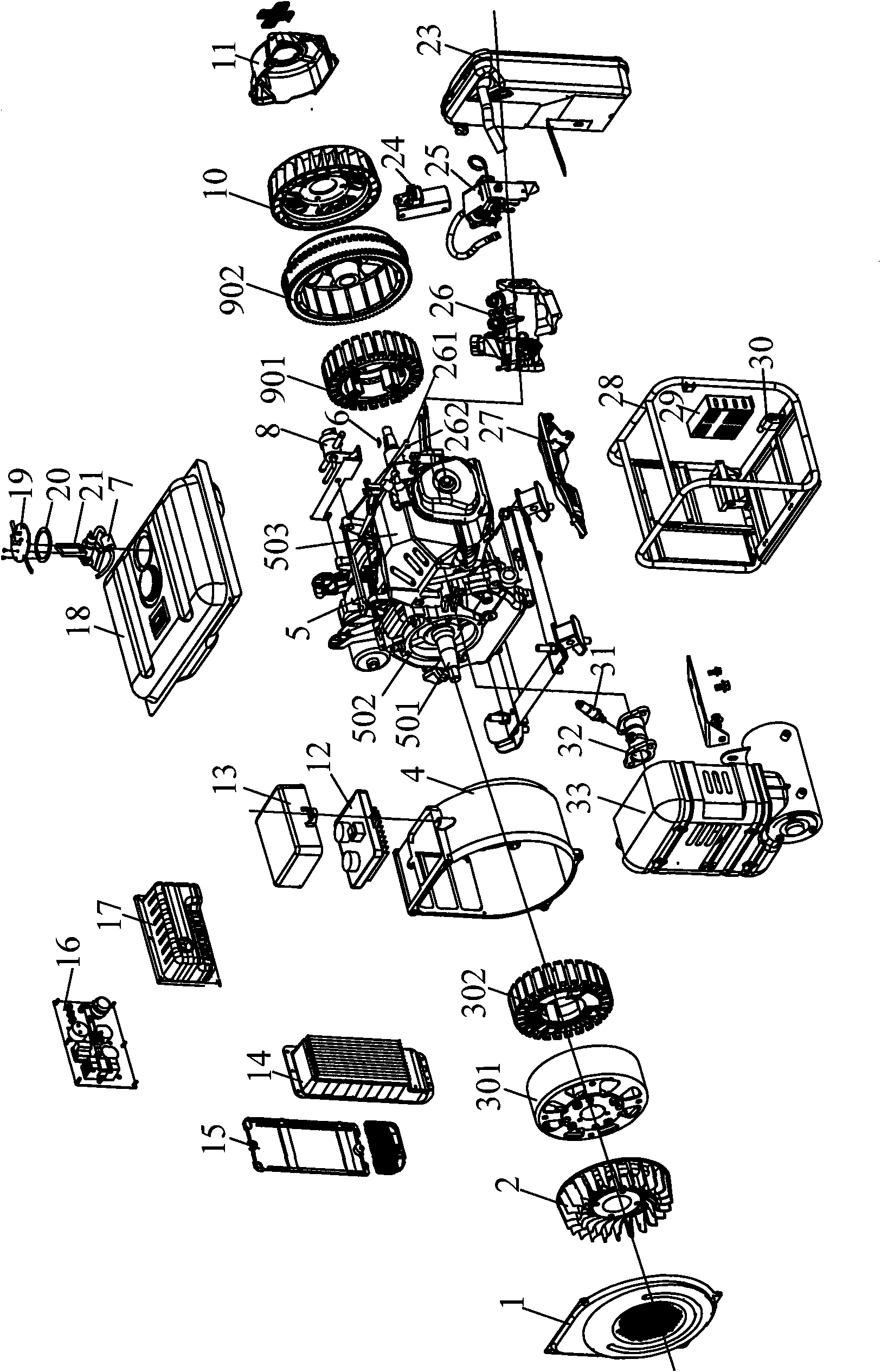

[0033] A preferred embodiment will be given below, and the present invention will be described more clearly and completely in conjunction with the accompanying drawings.

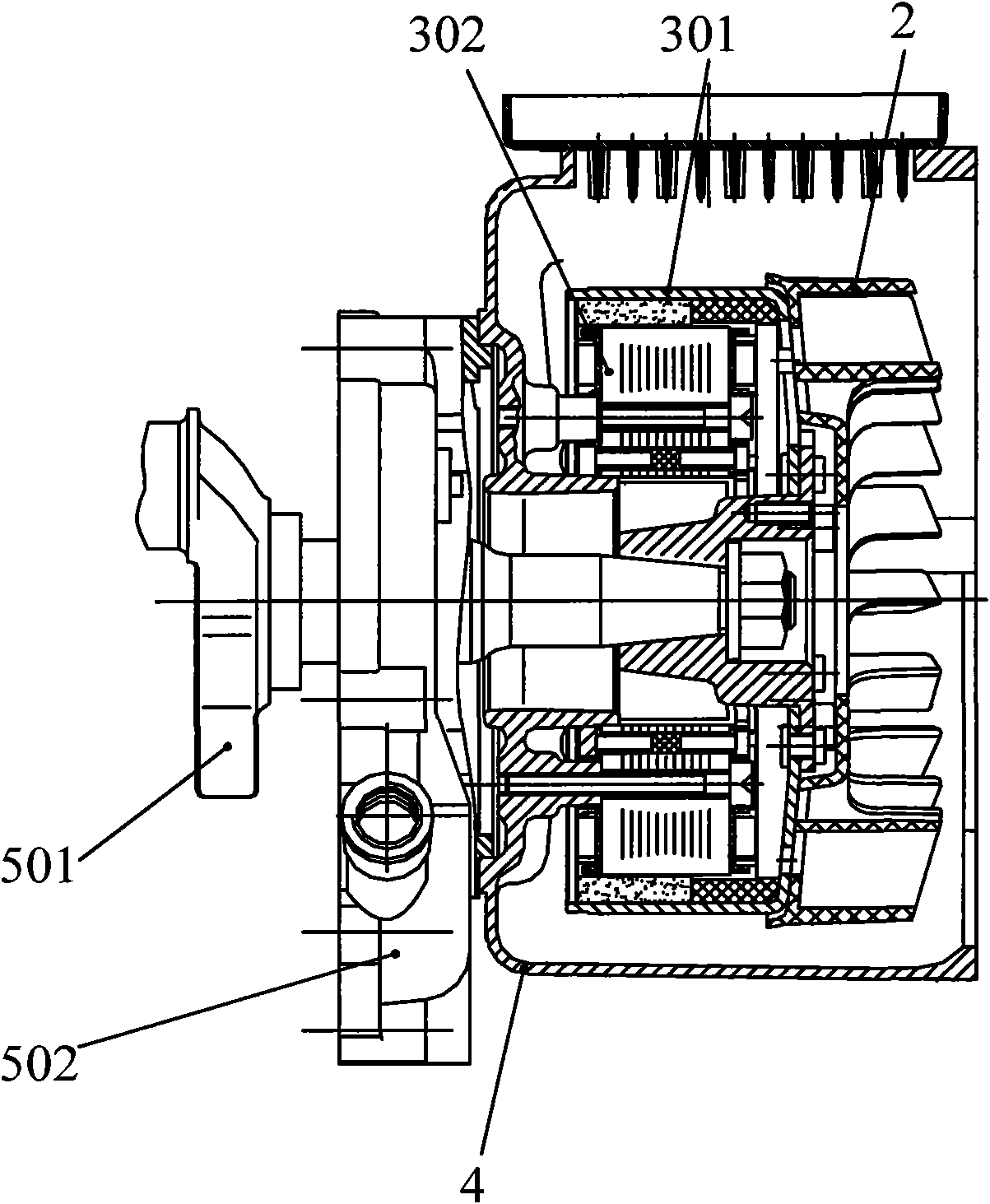

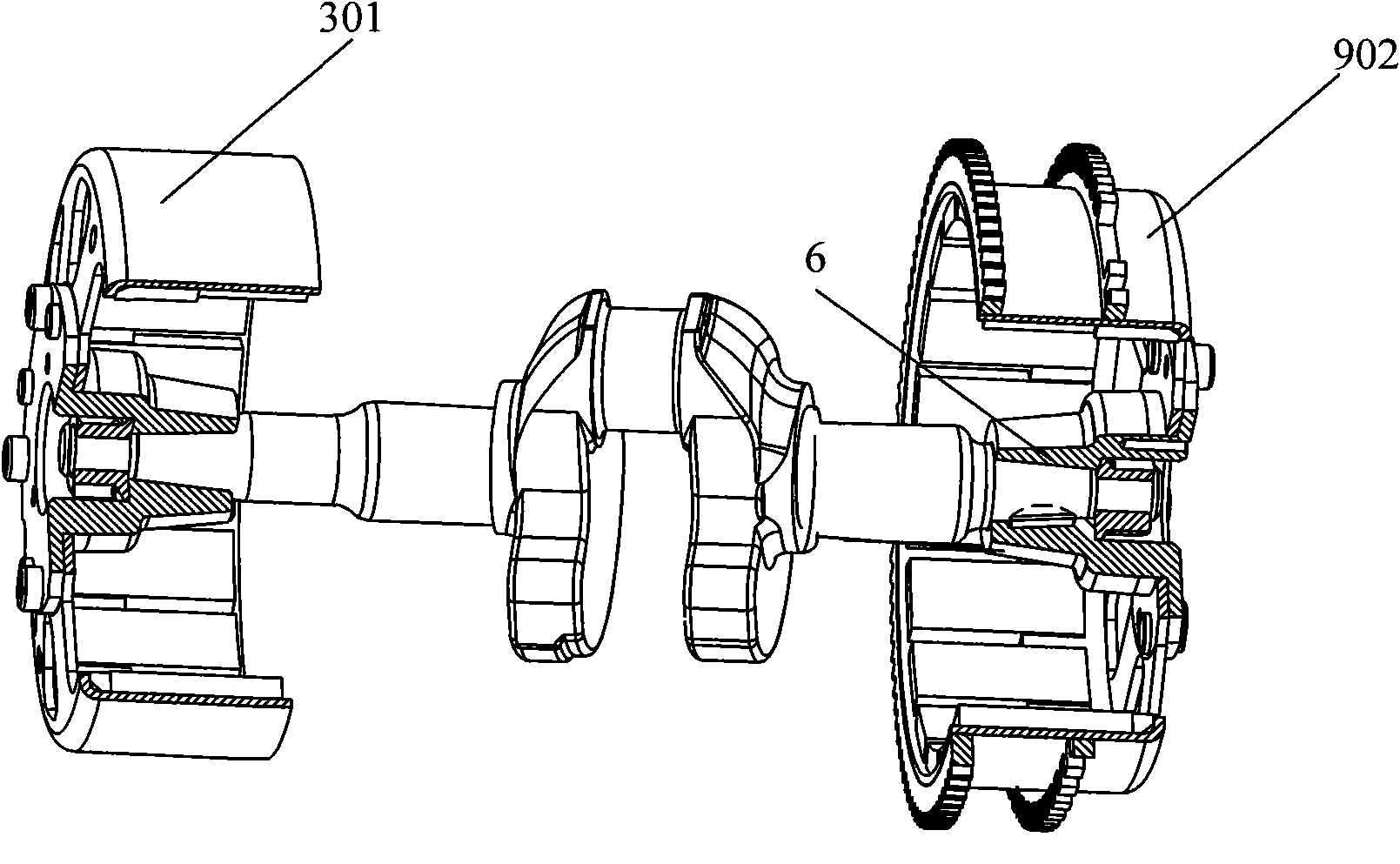

[0034] like figure 1 As shown, the present invention adopts the single power driven double generating set of EFI system to include generator rear cover 1, left cooling fan 2, left generator, left wind guide cover 4, engine 5, fuel filter 7, fuel pressure Regulator 8, right generator, right cooling fan 10, right wind guide cover 11, auxiliary inverter 12, auxiliary inverter cover 13, main inverter 14, main inverter cover 15, panel 16, panel rear cover 17 And fuel tank 18, connection block 19, gasket 20, fuel pump 21, air filter 23, crankshaft position sensor 24, damper pump 25, throttle assembly 26, second deflector 27, frame 28, ECU control box 29 , ignition coil 30, oxygen sensor 31, muffler intake pipe 32 and secondary muffler 33. like figure 2 As shown, the left generator includes a left generator rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com