Method for heating industrial pure titanium plate blank by common step-by-step heating furnace

A walking heating furnace, technology of industrial pure titanium, applied in temperature control, etc., can solve the problem of difficult heating of industrial pure titanium slabs, and achieve the effect of reducing investment costs and ensuring heating quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

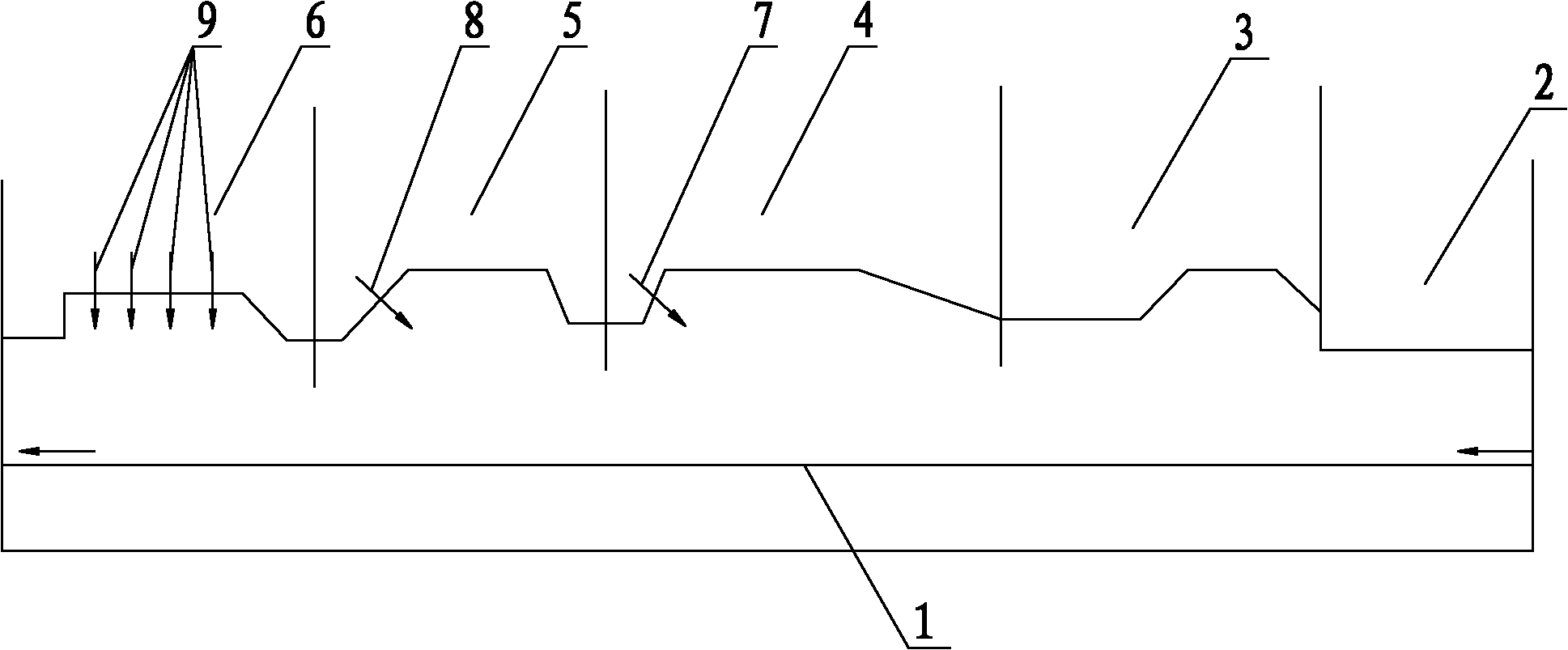

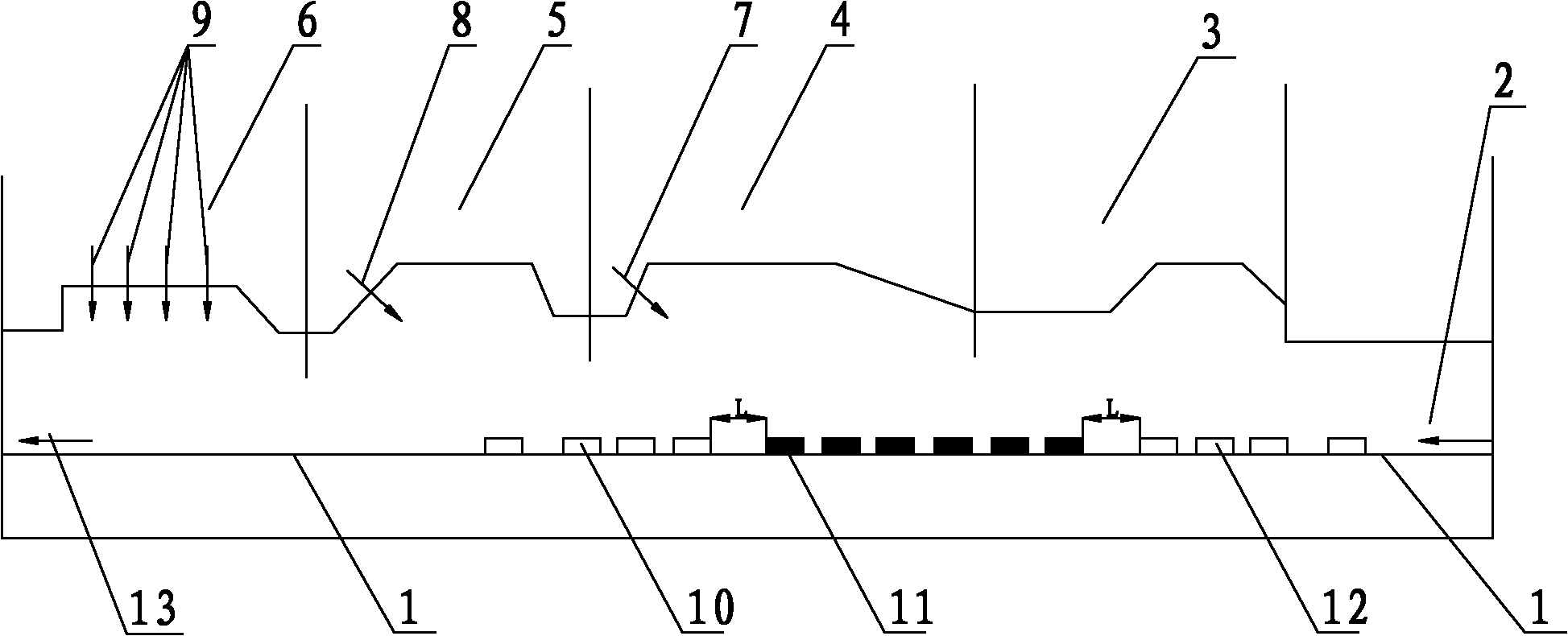

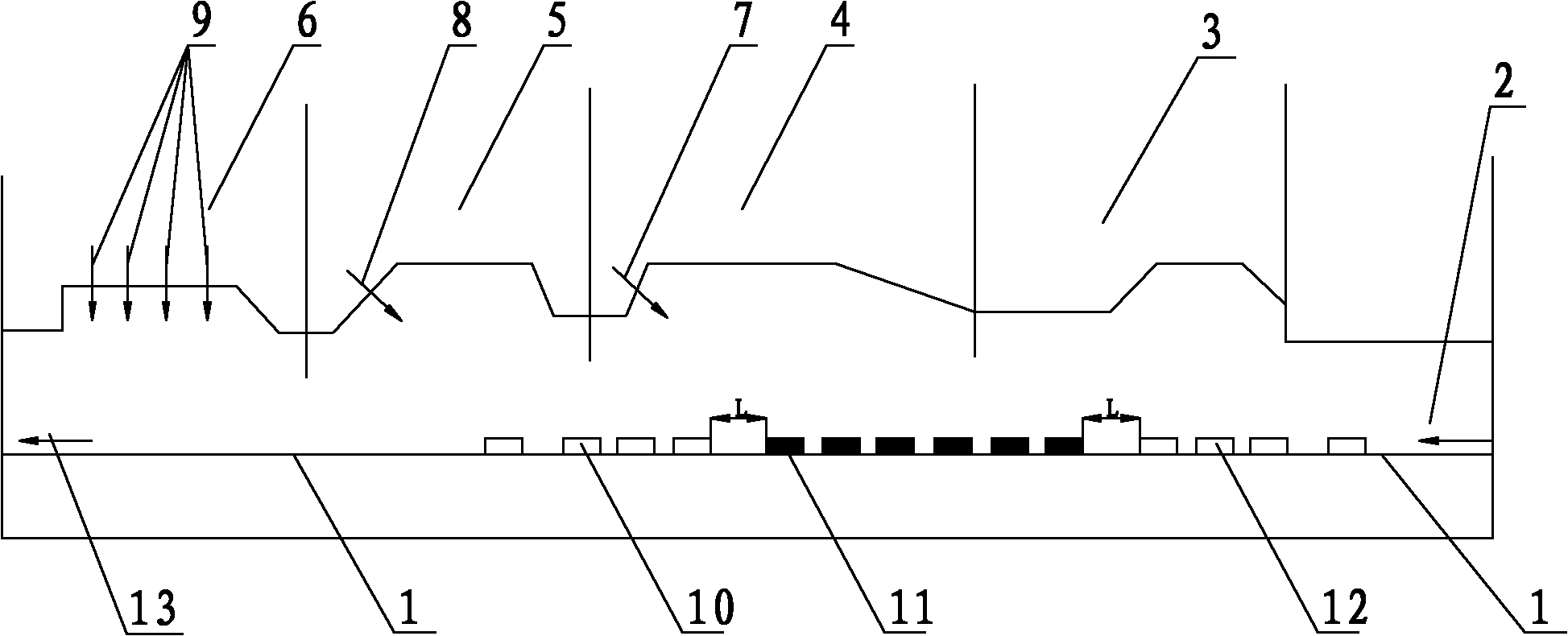

Method used

Image

Examples

Embodiment 1

[0028] In this embodiment, a common walking-type heating furnace for heating steel billets in a hot rolling mill is used to heat industrial pure titanium slabs with a thickness of 120 mm and a width of 1050 mm. The heating process is as follows: ① Arrange three billets before and after the industrial pure titanium billet; ② The distance between the front and rear billets of the industrial pure titanium slab and the titanium billet is 1 meter; ③ Turn off the heating section and preheating section during the heating process. Hot section burner, while controlling the furnace gas temperature of each heating section by adjusting the burning capacity of the soaking section burner; ④The heating temperature and heating time during the heating process are: the furnace gas temperature of the heat recovery section is 280℃, heating The time is 32 minutes; the gas temperature in the preheating section is 350℃, and the heating time is 40 minutes; the gas temperature in the heating section is ...

Embodiment 2

[0030] In this embodiment, a common walking-type heating furnace for heating steel billets in a hot rolling mill is used to heat industrial pure titanium slabs with a thickness of 220 mm and a width of 1250 mm. The heating process is as follows: ① five billets are arranged before and after the industrial pure titanium billet; ② the distance between the billet and the industrial pure titanium billet is 2 meters; ③ the heating section and preheating section burners are closed during the industrial heating process, and at the same time The furnace gas temperature of each heating section is controlled by adjusting the burning capacity of the burner in the soaking section; ④The heating temperature and heating time during the heating process are: the furnace gas temperature in the heat recovery section is 560℃, and the heating time is 65 minutes; The furnace gas temperature in the hot zone is 680°C and the heating time is 78 minutes; the furnace gas temperature in the heating zone is ...

Embodiment 3

[0032] In this embodiment, a common walking-type heating furnace for heating steel billets in a hot rolling mill is used to heat industrial pure titanium slabs with a thickness of 180 mm and a width of 1050 mm. The heating process is as follows: ① Arrange four billets before and after the industrial pure titanium billet; ② The distance between the billet and the industrial pure titanium billet is 1.5 meters; ③ Close the heating section and preheating section burners during the industrial heating process, and at the same time The gas temperature of each heating section is controlled by adjusting the burning capacity of the burner in the soaking section; ④The heating temperature and heating time during the heating process are: the furnace gas temperature in the heat recovery section is 450°C, and the heating time is 46 minutes; The furnace gas temperature in the hot zone is 580°C and the heating time is 58 minutes; the furnace gas temperature in the heating zone is 750°C and the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com