Bottle blank plug of heater of plastic bottle blank

A heater and plastic bottle technology, applied in the field of preform plugs, can solve the problems of affecting the heating quality of plastic preforms, no expansion device, and preform tilting, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

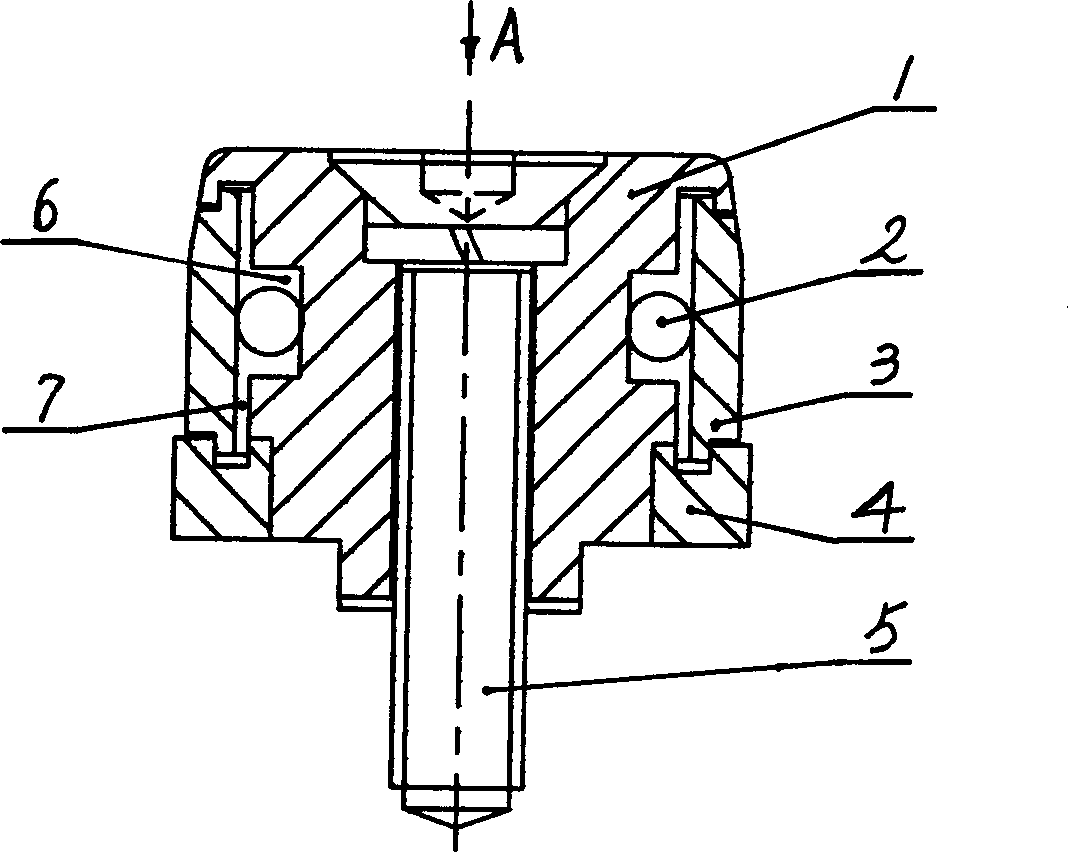

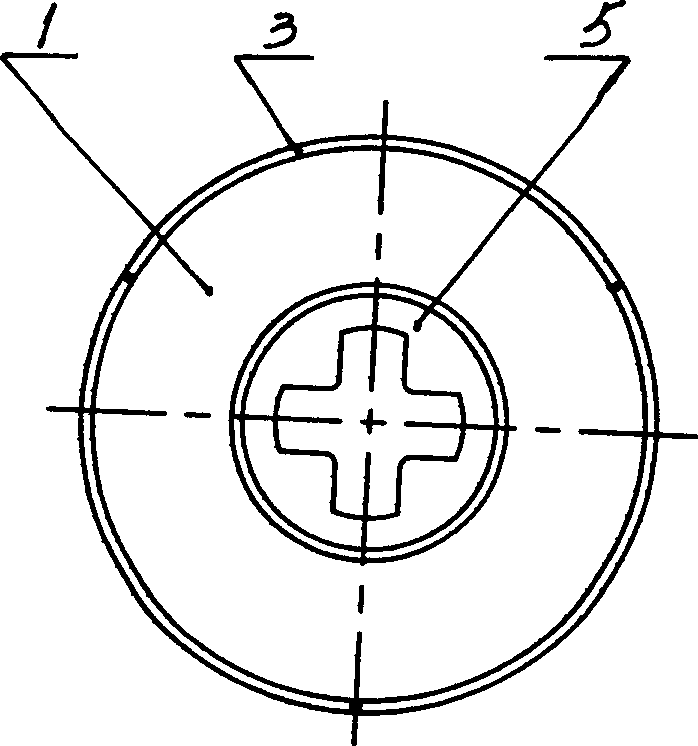

[0007] The invention discloses a bottle blank plug of a plastic bottle blank heater, which is a part of the plastic bottle blank heater. The main structure has a main body 1. The main body is connected to the preform conveying mechanism. The preform conveying mechanism is generally a carrying mechanism driven by a chain. The connection can be as follows: figure 1 Connected by screws 5 as shown. It is characterized in that the outer wall of the main body 1 is formed with a movable groove 7, and a movable ring piece 3 is installed in the movable groove. Due to processing needs, one end of the movable ring piece 3 is fixed by a limit pad 4, and the limit pad 4 can be made of steel or copper. Material is made, and copper heat dissipation is good, elastic ring 2 is installed in the inboard of movable ring sheet 3. With the movable ring piece and the elastic ring, the size of the shape of the plug can be automatically adjusted, and the inner mouth of the plastic preform can be tigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com