Production process of large-thickness high-performance pre-hardened SM4Cr2Mn plastic mold steel plates

A technology for plastic molds and production processes, applied in metal rolling and other directions, can solve the problems of poor quality stability, limited billet thickness, low efficiency, etc., to achieve uniform performance, reduce the hardness difference of the whole plate, and reduce production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

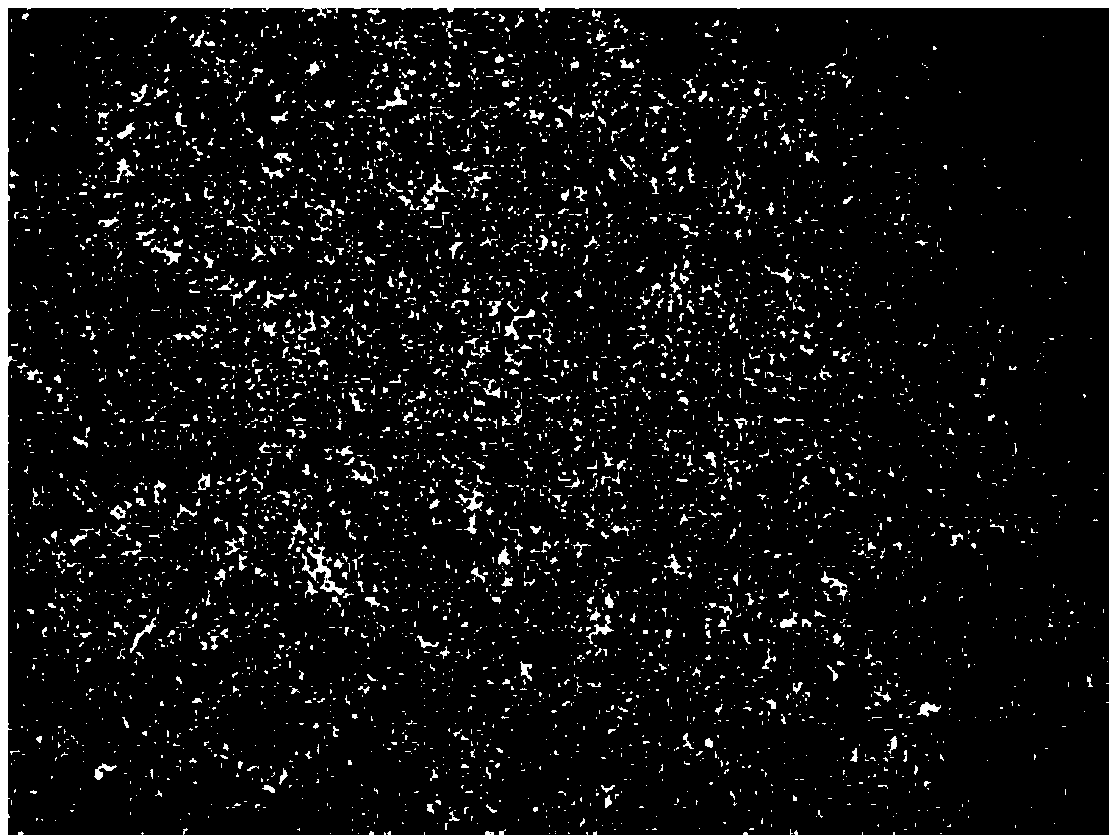

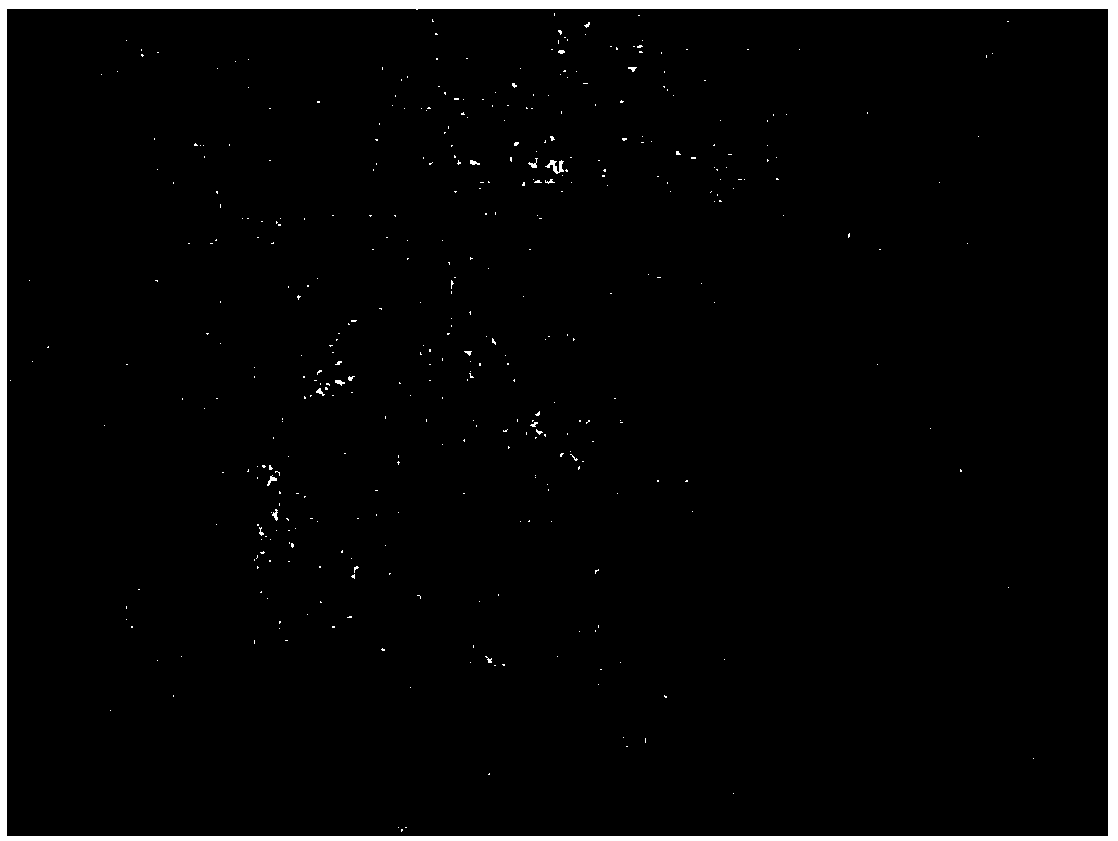

Image

Examples

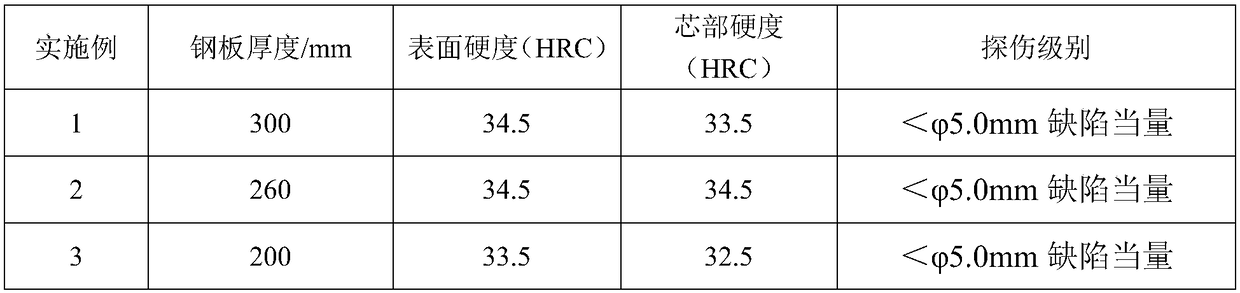

Embodiment 1

[0034] The thickness of the large-thickness high-performance pre-hardened SM4Cr2Mn plastic mold steel plate that this embodiment relates to is 300mm, and its chemical composition is calculated by mass percentage: C: 0.43%, Si: 0.28%, Mn: 1.55%, P: 0.005% , S: 0.002%, Cr: 1.95%, Mo: 0.23%, and the balance is Fe and unavoidable impurity elements.

[0035] The manufacturing process of the steel plate is as follows:

[0036] Production process: converter steelmaking→refining→vacuum degassing→continuous casting of φ900*1450mm ellipse billet→hot delivery→heating in soaking furnace→rolling→heat treatment→flaw detection→finishing→inspection→warehousing.

[0037] The specific operation of the main process is as follows:

[0038] Refining and vacuum degassing treatment reduce five harmful elements in steel; continuous casting with low superheat and constant drawing speed, and adopt electromagnetic stirring and light reduction technology to ensure the internal quality of φ900*1450mm ova...

Embodiment 2

[0044]The thickness of the large-thickness high-performance pre-hardened SM4Cr2Mn plastic mold steel sheet that this embodiment relates to is 260mm, and its chemical composition is calculated by mass percentage: C: 0.41%, Si: 0.28%, Mn: 1.50%, P: 0.006% , S: 0.002%, Cr: 1.95%, Mo: 0.20%, and the balance is Fe and unavoidable impurity elements.

[0045] The manufacturing process of the steel plate is as follows:

[0046] Production process: converter steelmaking→refining→vacuum degassing→continuous casting of φ900*1450mm ellipse billet→hot delivery→heating in soaking furnace→rolling→heat treatment→flaw detection→finishing→inspection→warehousing.

[0047] The specific operation of the main process is as follows:

[0048] Refining and vacuum degassing treatment reduce five harmful elements in steel; continuous casting with low superheat and constant drawing speed, and adopt electromagnetic stirring and light reduction technology to ensure the internal quality of φ900*1450mm oval...

Embodiment 3

[0054] The thickness of the large-thickness high-performance pre-hardened SM4Cr2Mn plastic mold steel plate that this embodiment relates to is 200mm, and its chemical composition is calculated by mass percentage: C: 0.40%, Si: 0.28%, Mn: 1.50%, P: 0.006% , S: 0.003%, Cr: 1.93%, Mo: 0.21%, and the balance is Fe and unavoidable impurity elements.

[0055] The manufacturing process of the steel plate is as follows:

[0056] Production process: converter steelmaking→refining→vacuum degassing→continuous casting of φ900*1450mm ellipse billet→hot delivery→heating in soaking furnace→rolling→heat treatment→flaw detection→finishing→inspection→warehousing.

[0057] The specific operation of the main process is as follows:

[0058] Refining and vacuum degassing treatment reduce five harmful elements in steel; continuous casting with low superheat and constant drawing speed, and adopt electromagnetic stirring and light reduction technology to ensure the internal quality of φ900*1450mm ova...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com