Scale separation and purification method of pentaxanthin amylose

A technology for separation and purification of sea urchin yellow, applied in the field of biomedicine, can solve the problems of inconvenient large-scale industrial production of sea urchin yellow polysaccharide, reduce sample volume, and cannot remove impurities, etc., and achieve large-scale production with high value, good purity, and increased yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

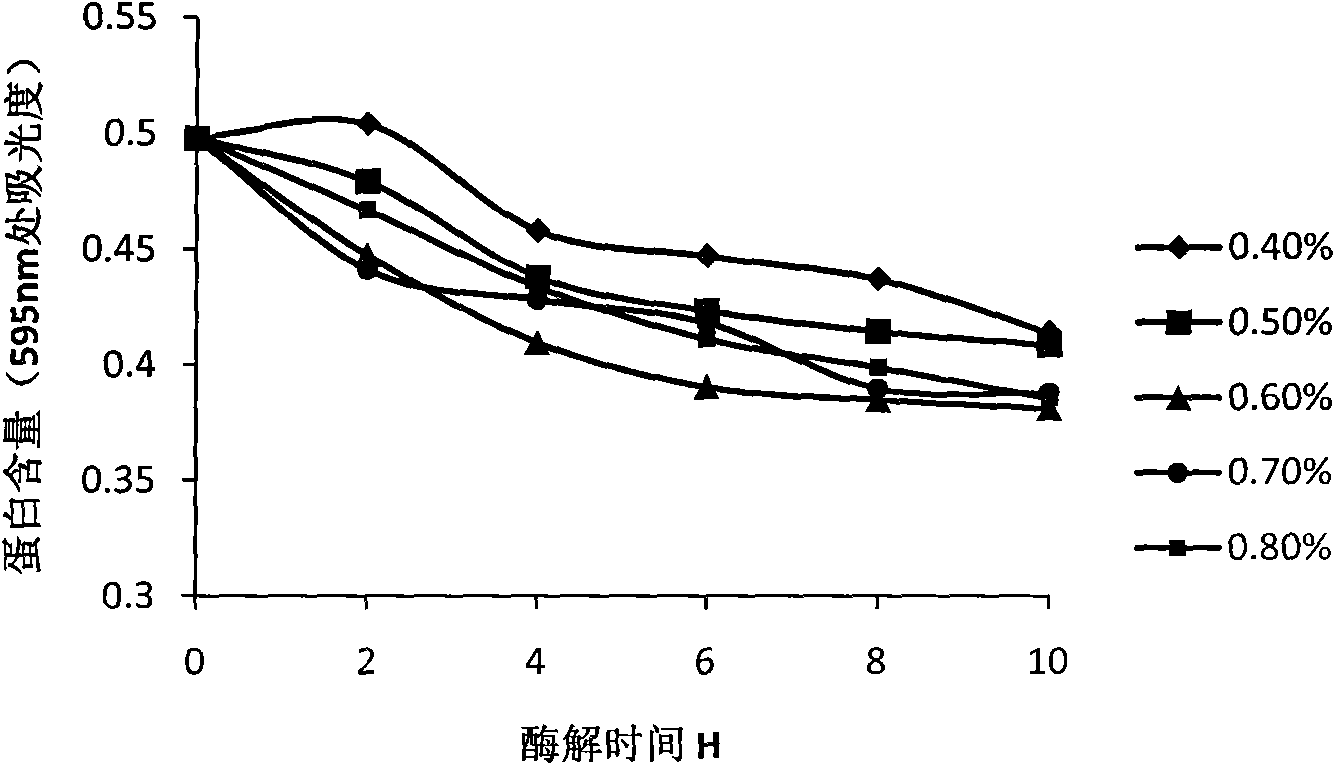

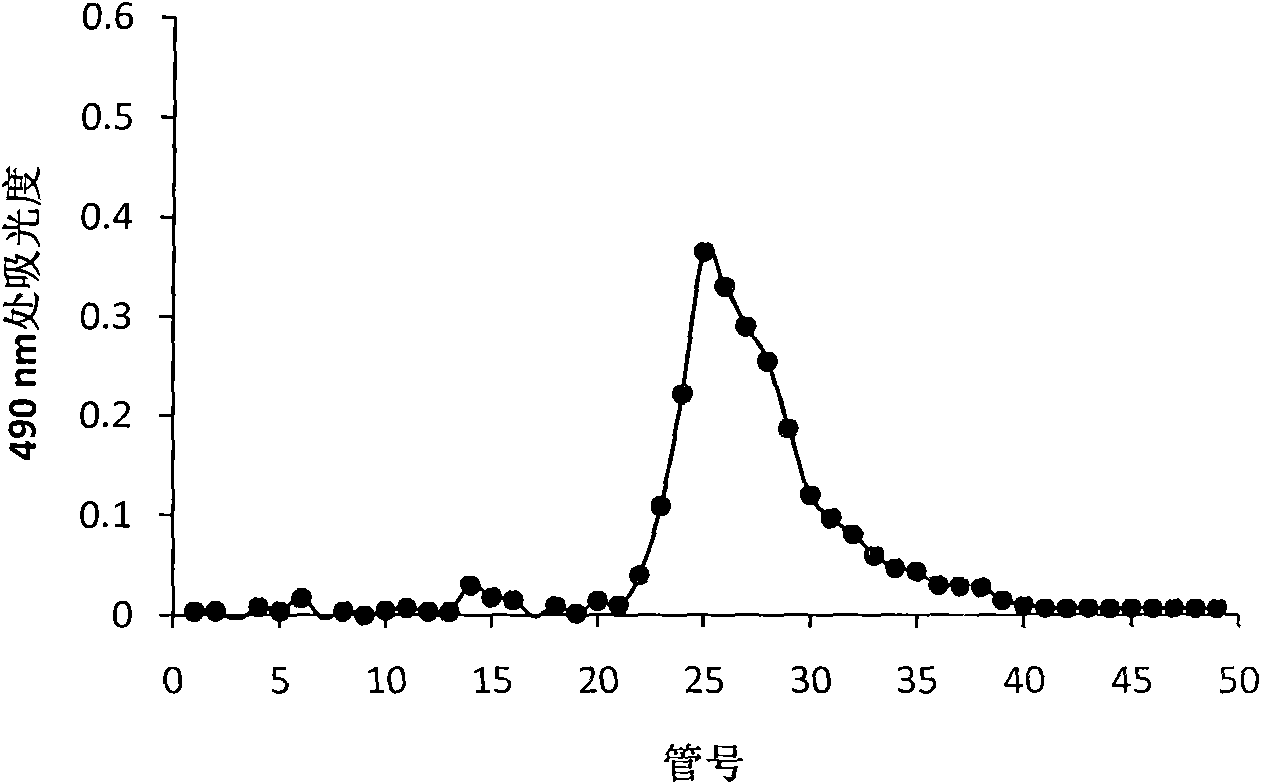

Embodiment 1

[0029]Take 50kg of fresh Echinococcus glabra sea urchin as raw material, take the yellow and weigh about 10kg, cut it into small pieces, put it in a stirring tank, add an equal volume of acetone, stir it to make it fully contact with the acetone, let it stand for 30min, discard the upper layer of acetone , repeated 8 times until the acetone layer is basically colorless, finally the acetone is evaporated to dryness under reduced pressure, and ground to make 1.5kg of sea urchin yellow acetone powder. Put 1.5kg of sea urchin yellow acetone powder in 30 times of water (112L), cook at 90°C for 6h, extract twice, collect the extract, concentrate under reduced pressure to 56L. For papain enzymatic deproteinization, adjust the pH of sea urchin yellow extract to 6.5, add 0.6% (w / w) papain, incubate at 60°C for 24h, heat at 90°C for 15min to inactivate the enzyme, and collect the supernatant by centrifugation. Select an ultrafiltration membrane with a cut-off molecular weight of 100K to...

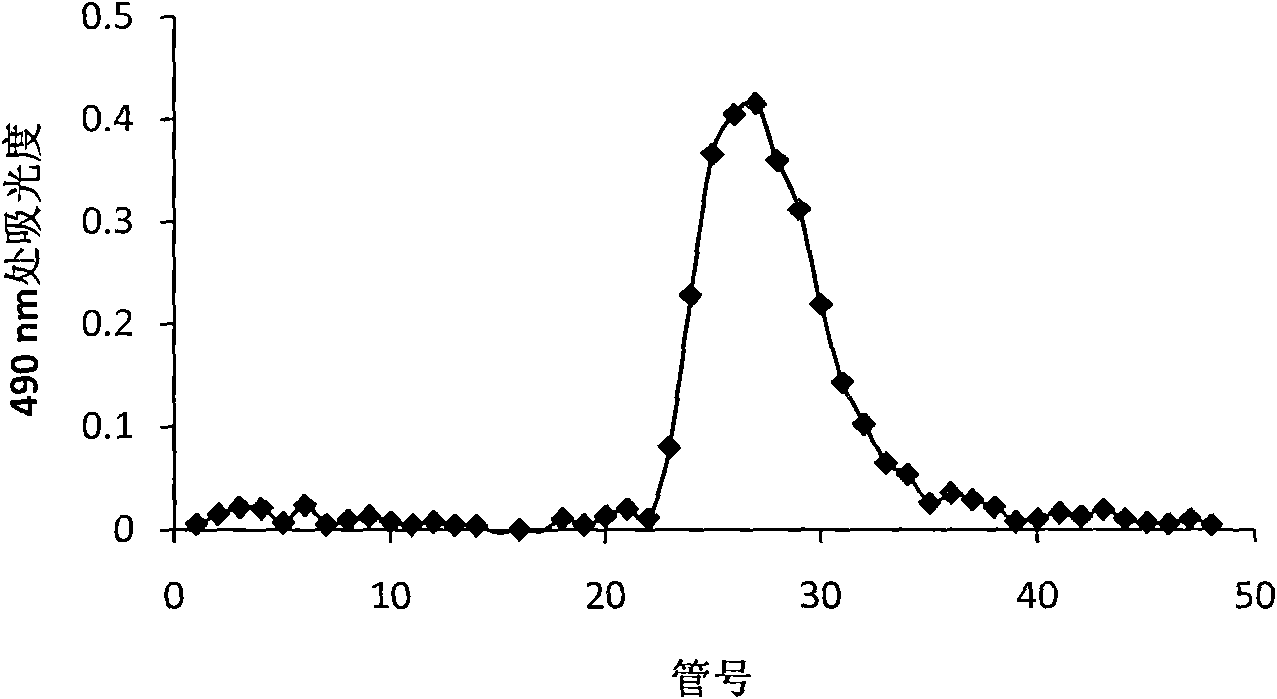

Embodiment 2

[0033] Take 100kg of fresh Echinococcus glabra sea urchin as the raw material, take the yellow and weigh about 20kg, cut it into small pieces, put it in a mixing tank, add an equal volume of acetone, stir it to make it fully contact with the acetone, let it stand for 30min, discard the upper layer of acetone , repeated several times until the acetone layer is substantially colorless (about 6-8 times), finally the acetone is evaporated to dryness under reduced pressure, and ground to make 3 kg of sea urchin yellow acetone powder. Put 3kg of sea urchin yellow acetone powder in 30 times of water (225L), cook at 90°C for 6h, extract twice, collect the extract, concentrate under reduced pressure to 112L. For papain enzymatic deproteinization, adjust the pH of sea urchin yellow extract to 6.5, add 0.6% (w / w) papain, incubate at 60°C for 20h, heat at 90°C for 15min to inactivate the enzyme, and collect the supernatant by centrifugation. Select an ultrafiltration membrane with a cut-o...

Embodiment 3

[0037] Take 200kg of fresh Echinococcus glabra sea urchin as the raw material, take the yellow and weigh about 40kg, cut it into small pieces, put it in a mixing tank, add an equal volume of acetone, stir it to make it fully contact with the acetone, let it stand for 30min, discard the upper layer of acetone , repeated several times until the acetone layer is basically colorless (about 6-8 times), finally the acetone is evaporated to dryness under reduced pressure, and ground to make 6 kg of sea urchin yellow acetone powder. Put 3kg of sea urchin yellow acetone powder in 30 times of water (450L), cook at 90°C for 6h, extract twice, collect the extract, concentrate under reduced pressure to 224L. For papain enzymatic deproteinization, adjust the pH of sea urchin yellow extract to 6.5, add 0.6% (W / W) papain, incubate at 60°C for 22h, heat at 90°C for 15min to inactivate the enzyme, and collect the supernatant by centrifugation. Select an ultrafiltration membrane with a cut-off m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com