Hyposmosis/super-hyposmosis oil extraction sewage reinjection method in oil field

A technology for oil extraction sewage and treatment method, which is applied in biological water/sewage treatment, water/sludge/sewage treatment, sustainable biological treatment, etc. The effect of reducing the treatment process and residence time, reducing the energy consumption of aeration, and low suspended solids in the effluent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

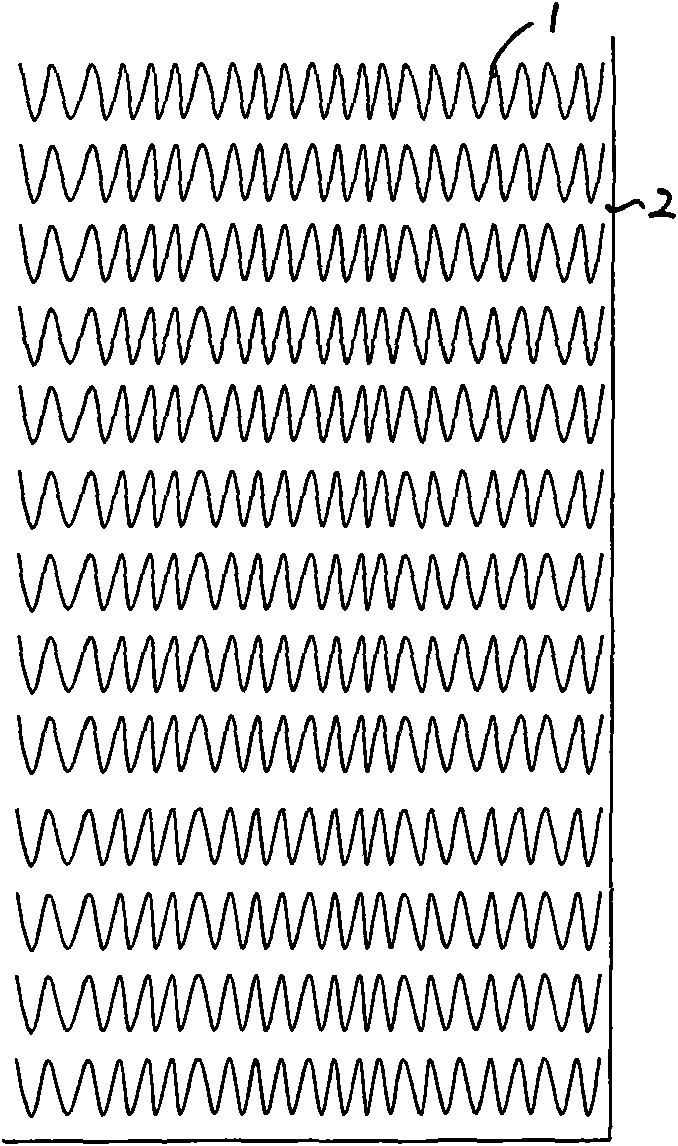

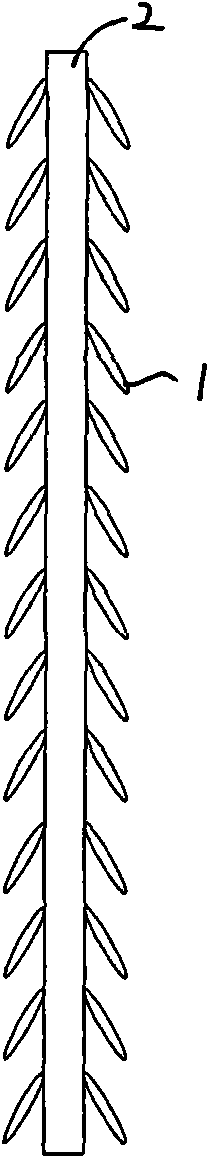

[0028] Example 1: see Figure 2-5 , the surface for contacting oxidation of the present invention has a fiber cloth sheet suspension filler, which is composed of a synthetic fiber cloth sheet 2 and a fiber thread 1 evenly distributed on both sides; the combined semi-soft suspension filler is composed of a middle plastic clip ring 4 and a uniform inner and outer perimeter. The distributed fiber filaments 3 and 6 form a sheet-like structure, which is composed of central ropes 5 connected in series. Both have relatively high density, which is beneficial to improve the contact time between the treated water and the filler and prevent short flow.

Embodiment 2

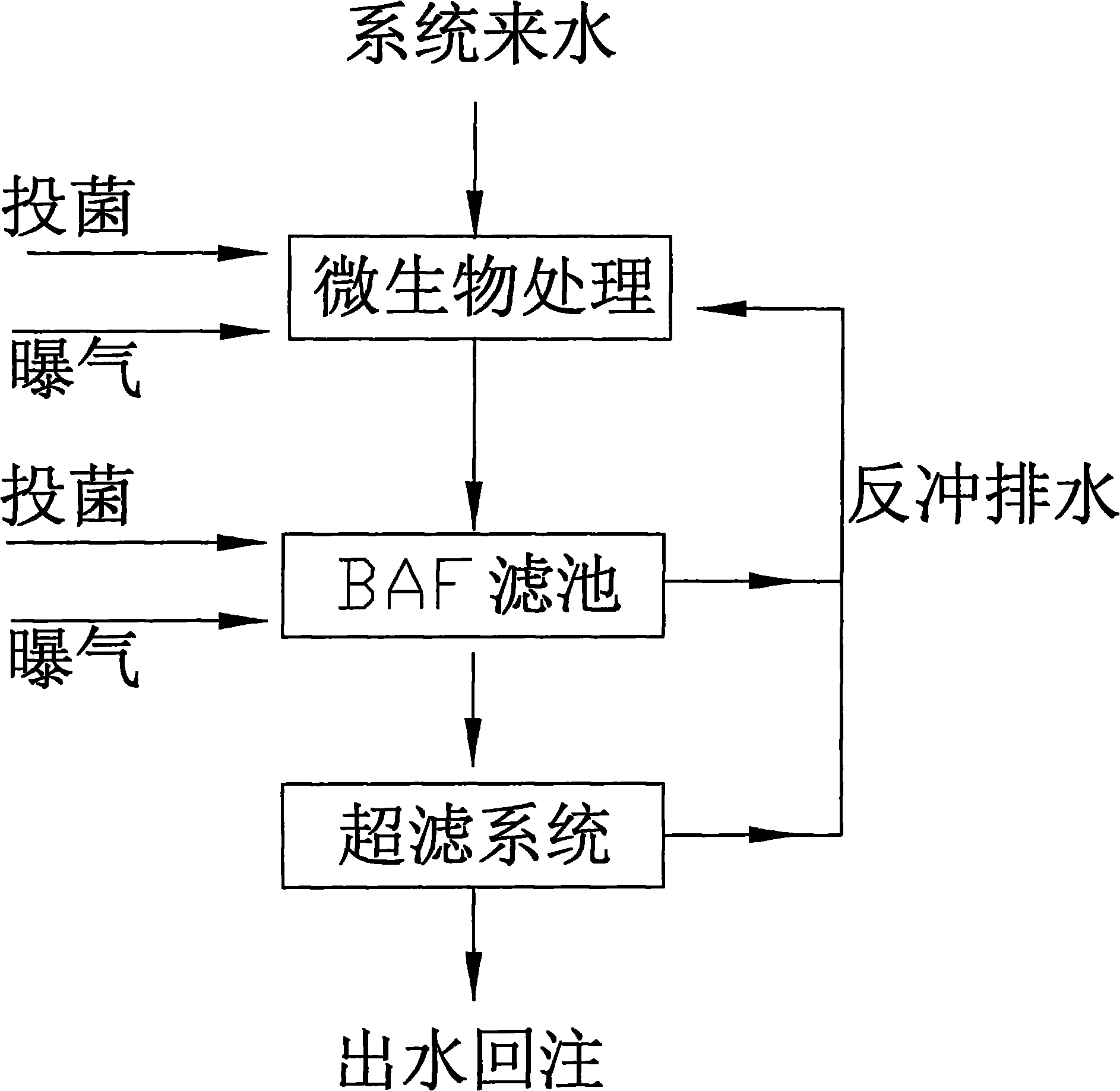

[0029] Example 2: The influent is the effluent from the descending tank of an oil field, and the sewage index (average value): oil content 300 mg / l, SS 565 mg / l. By adopting the process of the present invention, microbial contact oxidation + biological aeration filter + membrane separation (average pore diameter 100Nm). Among them, the contact oxidation reaction tank filler adopts Example 1 with a fiber cloth sheet hanging on the surface, and the filler has a filling density of 80V / V% in the tank. The microorganisms are: Zoogloeasp (Zoogloeasp), Bacillus cereus (Bacillus cereus), Pseudomonas alcaligenes (Pseudomonasalcaligenes) combination bacteria. The biological aeration filter adopts the applicant's previous patent application CN200620077234.7 with an internal circulation recirculation process. The bacteria on the surface of the filter material are: Brachybacterium collins, Bacillus licheniformis, Bacillus subtilis Bacillus subtilis (Bacillus subtilis), Pseudomonas (Pseudo...

Embodiment 3

[0030] Example 3: Basically the same as Example 2, wherein the contact oxidation filler adopts the combined semi-soft suspension filler of Example 1, and vertical partitions are arranged in the reaction tank, wherein the filler and filter material do not use protease-based active enzymes and Potassium, sodium, phosphorus, magnesium, calcium, amino acid and other trace elements dipping treatment, but the treatment time is longer than that of example 2, 5+3h, a total of 8h, the treatment results are basically the same as example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Median particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com