Preparation method of titanium dioxide powder with big particle diameter

A technology of titanium dioxide and large particle size, which is applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., can solve the problems of inappropriate domestic sales and high cost, and achieve the effects of low cost, easy control of synthesis conditions, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

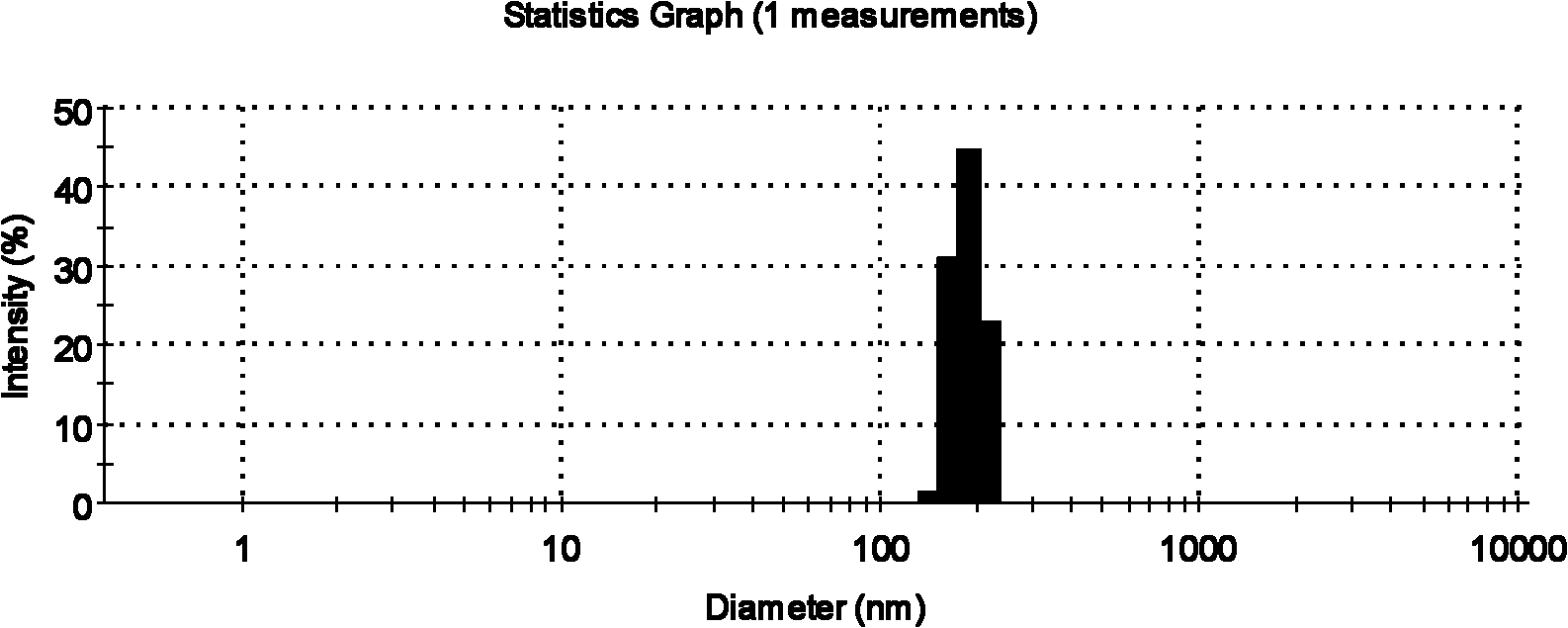

Image

Examples

Embodiment 1

[0012] Step 1: Under the condition of 15-20°C, mix titanyl sulfate with water to form a titanyl sulfate solution with a titanium ion concentration of 4mol / L, and then let stand for 12 hours;

[0013] Step 2: After clarifying and filtering the titanyl sulfate solution obtained in step 1, add 1 mol / L ammonia water to it, the molar ratio of the titanyl sulfate solution to ammonia water is 1:3, after the reaction is completed, a white precipitate appears and then wash the white precipitate until no sulfate remains;

[0014] Step 3: Separate the white precipitate in step 2, mix it with polyethylene glycol, citric acid and hydrogen peroxide at 30-80°C for peptization reaction, wherein, Ti 4+ , the molar ratio of polyethylene glycol, citric acid and hydrogen peroxide is 1:0.1:2:2, and then stand and age at 80°C for 12 hours to obtain a titanium dioxide gel;

[0015] Step 4: heat-treat the titanium dioxide gel obtained in step 3 at 1000° C. for 24 hours to obtain titanium dioxide pow...

Embodiment 2

[0017] Step 1: Under the condition of 15-20°C, mix titanyl sulfate with water to form a titanyl sulfate solution with a titanium ion concentration of 1 mol / L, and then let stand for 12 hours;

[0018] Step 2: After clarifying and filtering the titanyl sulfate solution obtained in step 1, add 1 mol / L ammonia water to it, the molar ratio of the titanyl sulfate solution to ammonia water is 1:6, after the reaction is completed, a white precipitate appears and then wash the white precipitate until no sulfate remains;

[0019] Step 3: Separate the white precipitate from step 2, mix it with polyethylene glycol, oxalic acid and hydrogen peroxide at 45°C for peptization reaction, wherein, Ti 4+ , the molar ratio of polyethylene glycol, oxalic acid and hydrogen peroxide is 1:0.1:10:10, and then stand and age at 30°C for 12 hours to obtain a titanium dioxide gel;

[0020] Step 4: heat-treat the titanium dioxide gel obtained in step 3 at 500° C. for 24 hours to obtain titanium dioxide po...

Embodiment 3

[0022] Step 1: Under the condition of 15-20°C, mix titanyl sulfate with water to form a titanyl sulfate solution with a titanium ion concentration of 2mol / L, and then let stand for 12 hours;

[0023] Step 2: After clarifying and filtering the titanyl sulfate solution obtained in step 1, add 1 mol / L ammonia water to it, the molar ratio of the titanyl sulfate solution to ammonia water is 1:5, after the reaction is completed, a white precipitate appears and then wash the white precipitate until no sulfate remains;

[0024] Step 3: Separate the white precipitate from step 2, mix it with polyethylene glycol, organic acid and hydrogen peroxide at 60°C for peptization reaction, wherein, Ti 4+ , the molar ratio of polyethylene glycol, organic acid and hydrogen peroxide is 1:0.1:4:4, and then stand and age at 50°C for 12 hours to obtain a titanium dioxide gel;

[0025] Step 4: heat-treat the titanium dioxide gel obtained in step 3 at 800° C. for 24 hours to obtain titanium dioxide pow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com