Method for preparing water-soluble sulfo-copolyester

A sulfocopolyester, water-soluble technology, applied in the field of preparation of water-soluble sulfopolyester, can solve the problems of difficult recovery of ethylene glycol, increased cost, difficult control of side reactions, etc., and achieves a simple preparation process and reduced cost , the effect of good sizing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

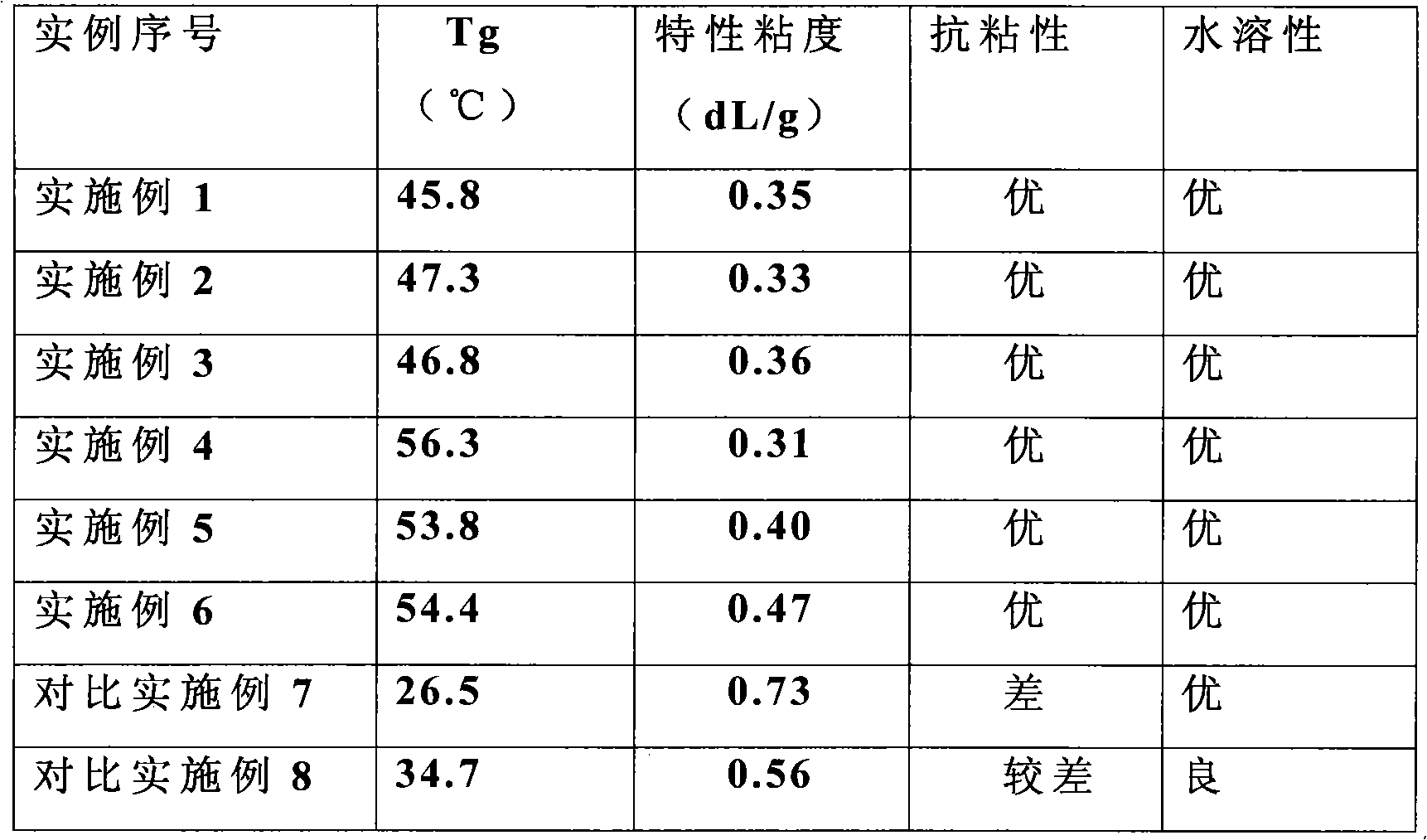

Examples

Embodiment 1

[0035] Raw material dosage

[0036] Isophthalic acid 37.92kg (228.2mol)

[0037] Dimethyl isophthalate-5-sodium sulfonate 29.63kg (100mol)

[0038] Terephthalic acid 93.05kg (560.1mol)

[0039] Ethylene glycol 85.27kg (1373.7mol)

[0040] 1,6-Adipic acid 7.74kg (53.0mol)

[0041] The molar ratio of dibasic acid to diol is 1:1.45

[0042] After mixing 37.92kg of isophthalic acid, 29.63kg of dimethyl isophthalate-5-sodium sulfonate, 93.05kg of terephthalic acid, 85.27kg of ethylene glycol, and 7.74kg of 1,6-adipic acid, Put it into a 300L stainless steel reaction kettle, and add 90g of antimony trioxide, 120g of sodium acetate, 100g of tetrabutyl titanate, 40g of trimethyl phosphite, protect the reaction system with pure nitrogen gas, and keep the system pressure at atmospheric pressure. Stir at 65rpm and heat up to 200-250°C for esterification. When the esterification rate reaches or exceeds 95% and all the theoretical by-products are evaporated, stop the esterification, ...

Embodiment 2-6

[0046] Similar to the steps and conditions of Example 1, only the raw materials and proportioning are different.

Embodiment 2

[0048] Raw material dosage

[0049] Isophthalic acid 41.53kg (250.0mol)

[0050] Sodium isophthalic acid-5-sulfonate 33.52kg (124.9mol)

[0051] Terephthalic acid 80.57kg (484.9mol)

[0052] Ethylene glycol 85.27kg (1373.7mol)

[0053] 1,6-Adipic acid 7.74kg (53.0mol)

[0054] The molar ratio of dibasic acid to diol is 1:1.50

[0055] Catalyst: 90g antimony acetate, 120g sodium acetate, 30g phosphoric acid

[0056] The properties of the obtained polyester are shown in Table (1).

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com