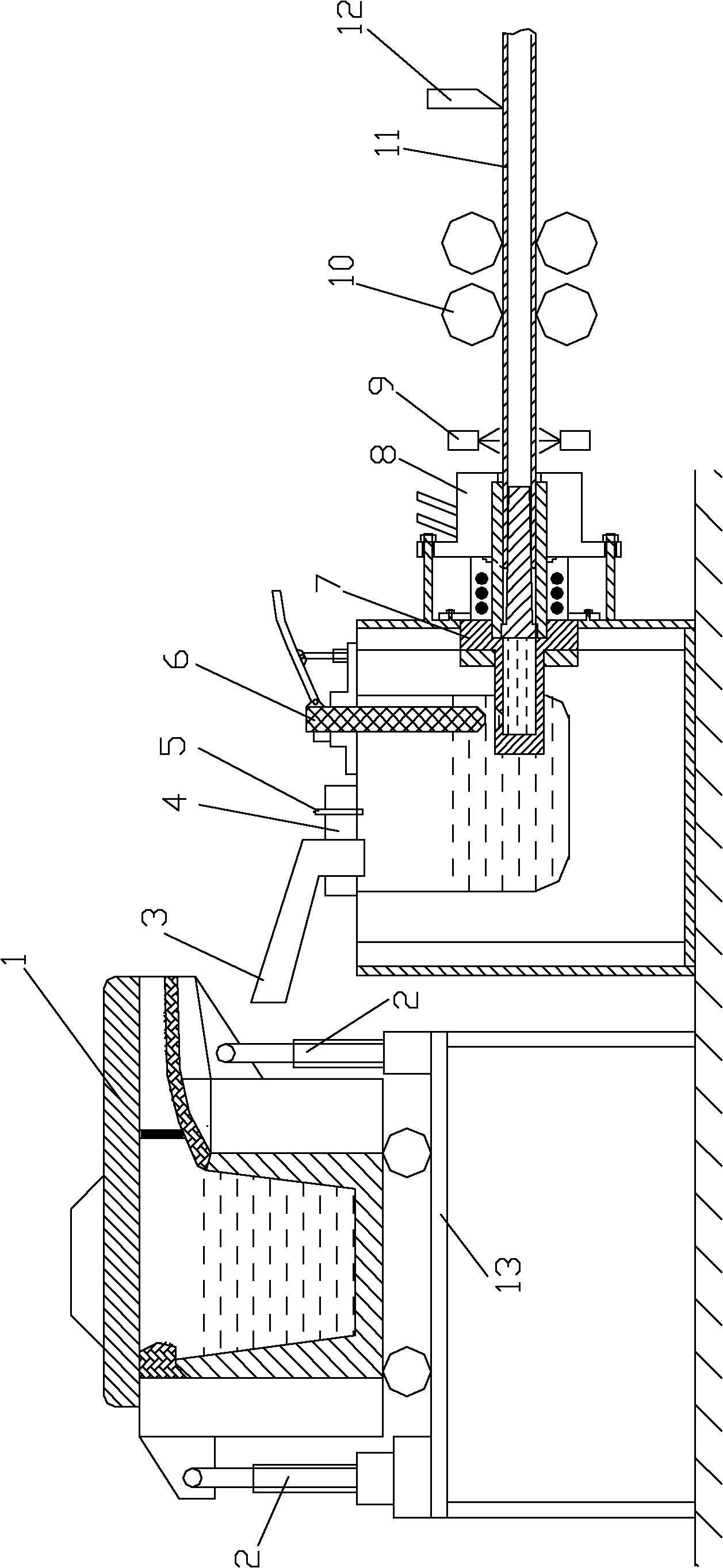

Hot-cold combined casting mould horizontal continuous casting equipment of cupronickel tubing and technology thereof

A technology of horizontal continuous casting and combination of hot and cold, applied in the field of material preparation, can solve the problems of poor surface quality of casting billets, large geometric loss of head and tail, and eccentric scrapping of billets, so as to achieve excellent surface quality, improve surface quality, and improve surface quality. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

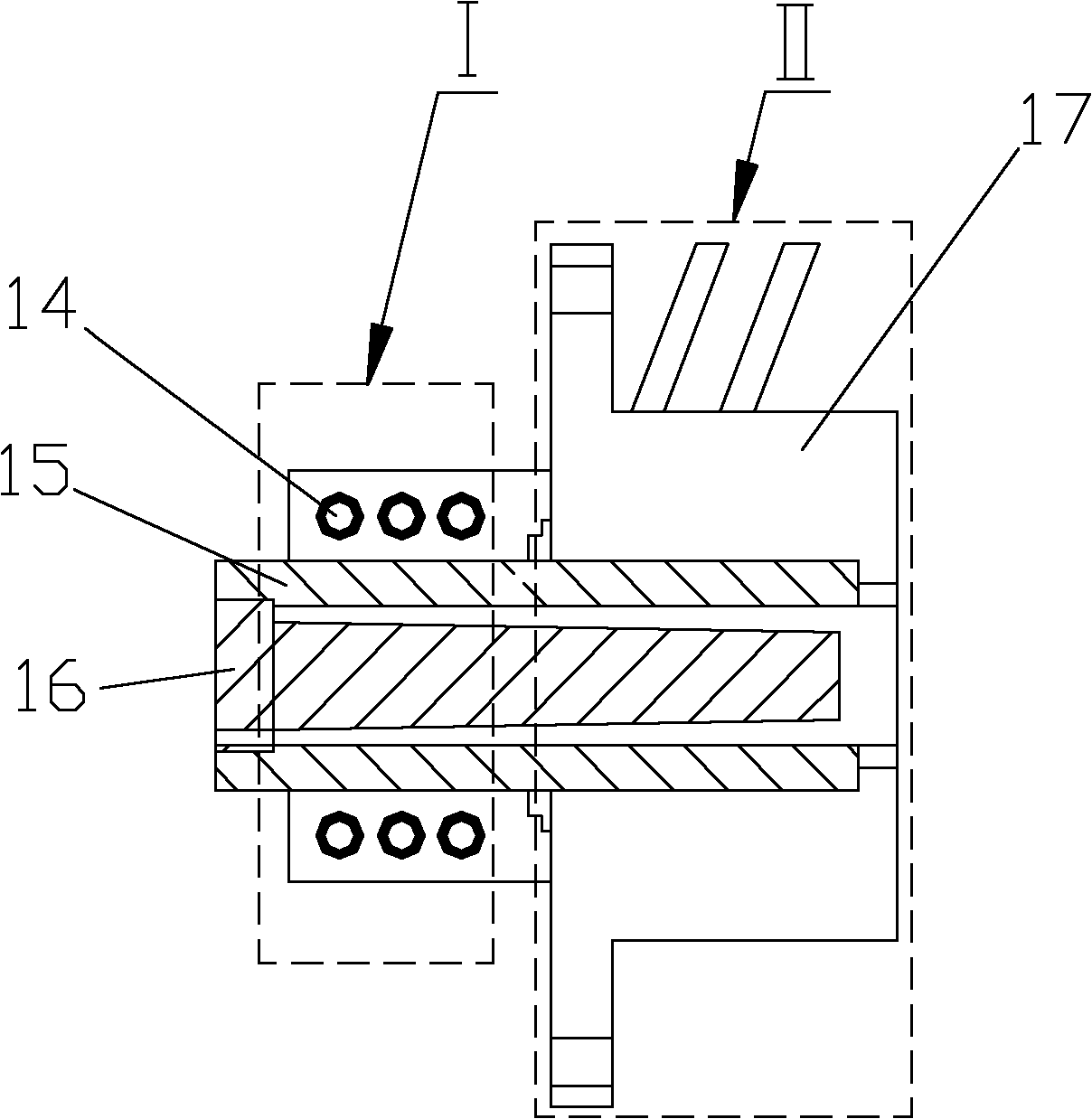

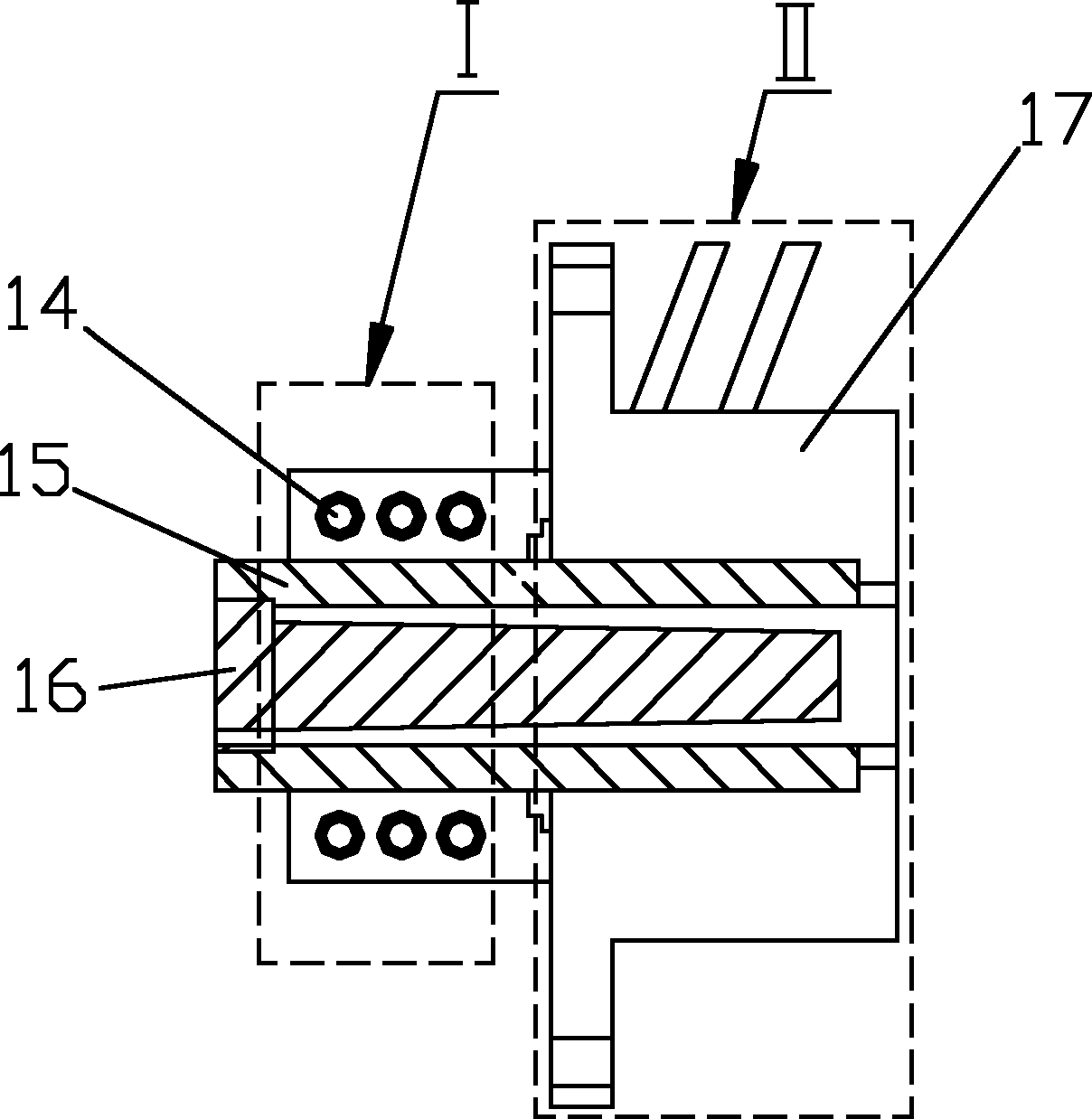

Method used

Image

Examples

Embodiment 1

[0040] Example 1: Continuous casting of BFe10-1-1 white copper pipes with a diameter of Ф50mm and a wall thickness of 5mm

[0041] The ratio is Ni 9.0%, Fe 1.0%, Mn 0.5% electrolytic nickel, pure iron, electrolytic manganese, and the remaining electrolytic copper is stacked in the melting furnace in sequence, heated and melted, the melting temperature is 1200 ℃, and the temperature of the holding furnace is 1200 ℃ ,

[0042] The hot type (mold heating) adopts high-frequency induction heating method, the heating frequency is 50kHz, the power is 20kW, the heating temperature of the hot type is 1200°C, the cooling water flow rate of the cold type (water-cooled copper sleeve) is 400L / h, and the traction speed is 200mm / min. The specification of the formed cupronickel pipe is Ф50×5mm BFe10-1-1, the inner surface and the outer surface of the pipe are smooth, the structure is a columnar crystal structure oriented along the axial direction of the pipe, and the mechanical properties o...

Embodiment 2

[0043] Example 2: Continuous casting of BFe10-1-1 white copper pipes with a diameter of Ф150mm and a wall thickness of 20mm

[0044] The ratio is Ni 11.0%, Fe 1.5%, Mn 1.0% electrolytic nickel, pure iron, electrolytic manganese, and the remaining electrolytic copper is stacked in the melting furnace in sequence, heated and melted, the melting temperature is 1250 ℃, and the temperature of the holding furnace is 1250 ℃ , the hot type (mold heating) adopts high-frequency induction heating method, the heating frequency is 50kHz, the power is 20kW, the heating temperature of the hot type is 1200°C, the cooling water flow rate of the cold type (water-cooled copper sleeve) is 1200L / h, and the traction speed is 50mm / min. The inner and outer surfaces, structure and mechanical properties of the formed pipe are similar to those in Example 1.

Embodiment 3

[0045] Example 3: Continuous casting of BFe30-1-1 white copper pipes with a diameter of Ф30mm and a wall thickness of 3mm

[0046] The ratio is Ni 32.0%, Fe 0.5%, Mn 1.2% electrolytic nickel, pure iron, electrolytic manganese, and the remaining electrolytic copper is stacked in the melting furnace in sequence, heated and melted, the melting temperature is 1350 ℃, and the temperature of the holding furnace is 1300 ℃ , The hot type (mold heating) adopts high-frequency induction heating method, the heating frequency is 50kHz, the power is 25kW, the heating temperature of the hot type is 1250°C, the cooling water flow rate of the cold type (water-cooled copper sleeve) is 1000L / h, and the traction speed is 500mm / min. The mechanical properties of the formed pipe = 45.4%, = 348 MPa, and the inner and outer surfaces and structures are similar to those in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com