Electric dialyzator for desalting fermentation liquor

An electrodialyzer and fermented liquid technology, applied in electrodialysis, general water supply saving, dispersed particle separation, etc., can solve the problems of lack of parameter monitoring and process control, high energy consumption of fermented liquid desalination, difficulty in long-term stable operation, etc., to achieve Realize unified management and process optimization control, improve the degree of automation, and promote the effect of engineering application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

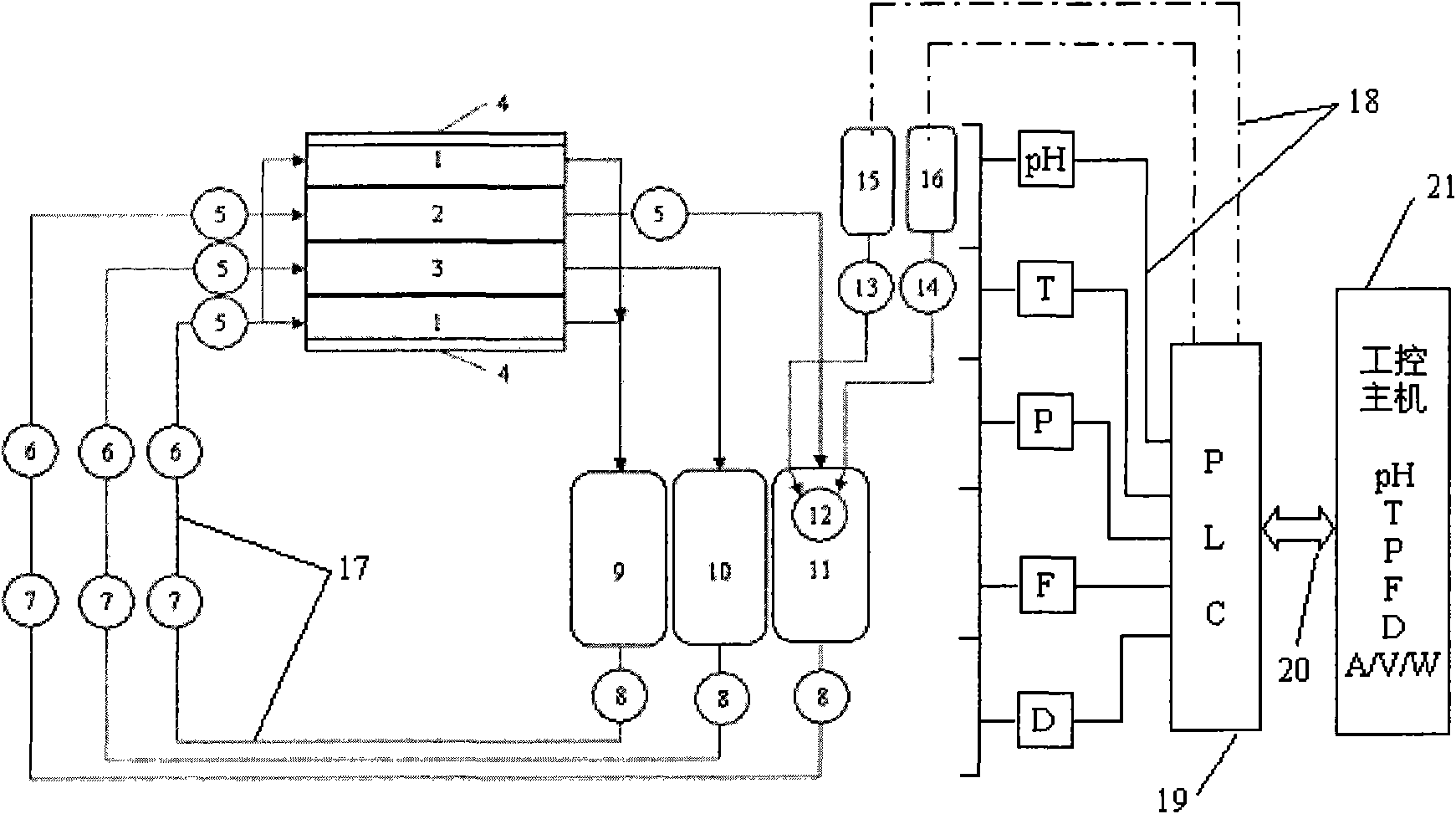

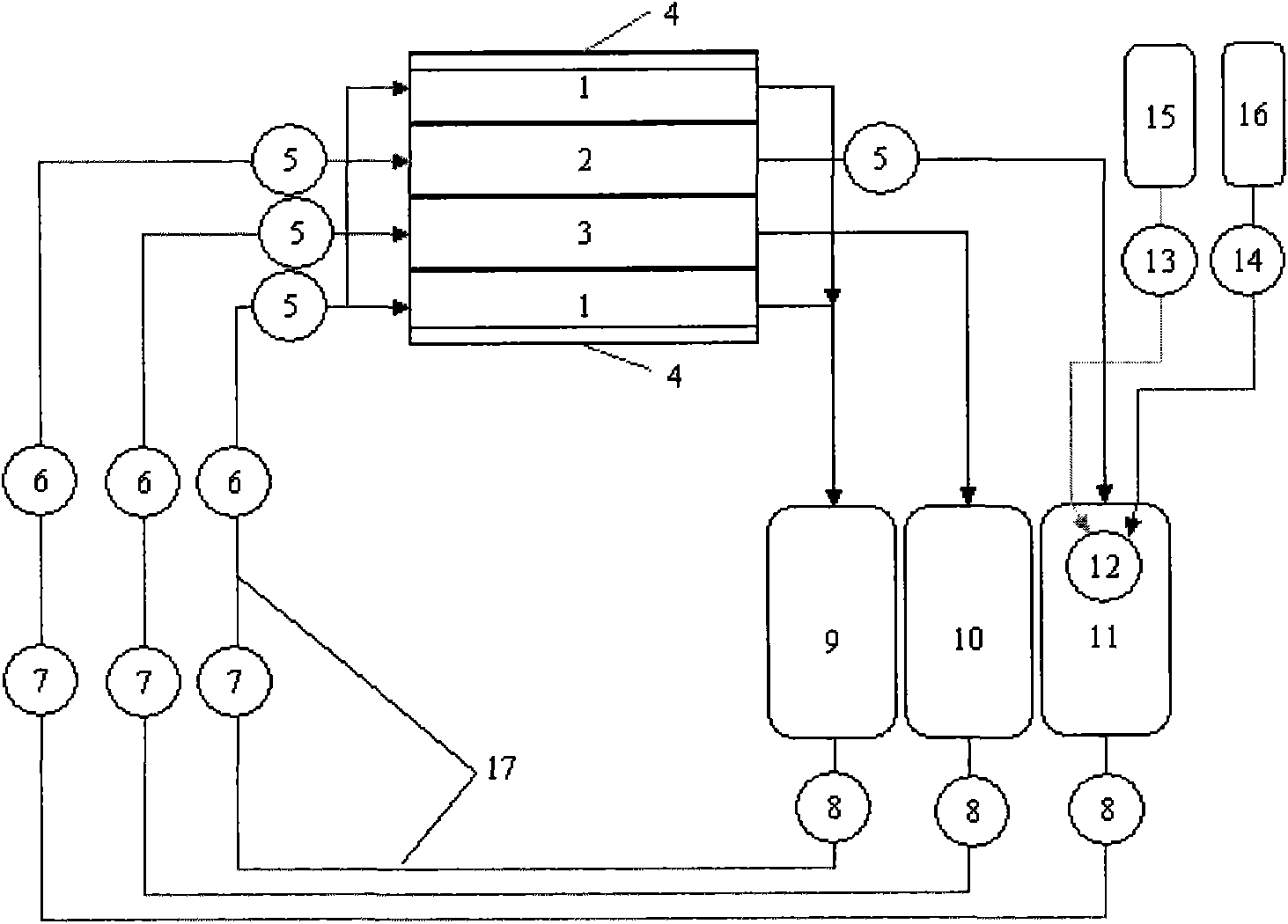

Method used

Image

Examples

Embodiment 1

[0052] Embodiment 1 adopts electrodialyzer of the present invention to reclaim glutamate from fermented liquid

[0053] The electrodialyzer of the present invention is used to recover glutamate from glutamic acid simulated fermentation broth. It operates intermittently at constant voltage 20V, constant temperature 30°C, and cycle. The initial feed of each chamber is as follows: desalination chamber: 1000ml glutamate simulated fermentation broth (100g L -1 Sodium glutamate or ammonium glutamate), the circulation flow is 100L h -1 ;Concentration chamber: 1000ml initial concentration is 1g L -1 Glutamate (sodium glutamate or ammonium glutamate) solution, the circulation flow rate is 100L h -1 ; Pole chamber: 1000ml 0.2mol L -1 Sodium sulfate solution, the circulation flow is 40L h -1 .

[0054] Glutamic acid simulated fermentation broth: With the prolongation of the running time, the concentration of the desalted solution gradually decreased, and the concentration of the co...

Embodiment 2

[0056] Embodiment 2 adopts electrodialyzer of the present invention to desalt from glutamic acid fermentation liquid

[0057] The electrodialyzer of the invention is used to remove sulfate from the simulated glutamic acid isoelectric mother liquor. It operates intermittently at a constant temperature of 30°C, constant pressure, and circulation. The initial feed is as follows: Desalination chamber: 1000ml sulfate simulated aqueous solution, circulation flow rate is 100L h -1 ;Concentration chamber: 1000ml initial concentration is 0.05mol L -1 Ammonium sulfate solution, the circulation flow rate is 100L h -1 ; Pole chamber: 1000ml 0.2mol L -1 Sodium sulfate solution, the circulation flow is 40L h -1 .

[0058] Simulated fermentation broth: investigate sulfate concentration, desalination rate, current efficiency and energy consumption during electrodialysis desalination of simulated solution. When the feed volume of the desalting chamber: the feed volume of the concentratin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| salt rejection rate | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

| salt rejection rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com