Method for preparing pore diameter controllable through hole anodized aluminum oxide film

A technology of anodic aluminum and anodic oxidation, which is used in the preparation of through-hole anodic aluminum oxide film, the preparation of anodic aluminum oxide film, and the field of controllable pore size, which can solve the problem of nano-pore size containing other impurities, and the process of stripping and removing aluminum is cumbersome and inaccurate. control and other problems, to achieve the effect of regular and orderly pore structure, high toughness and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

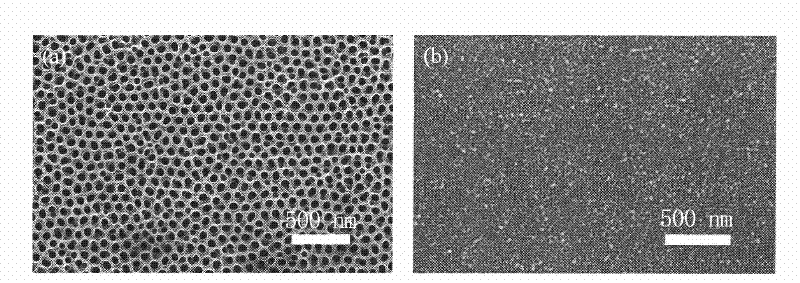

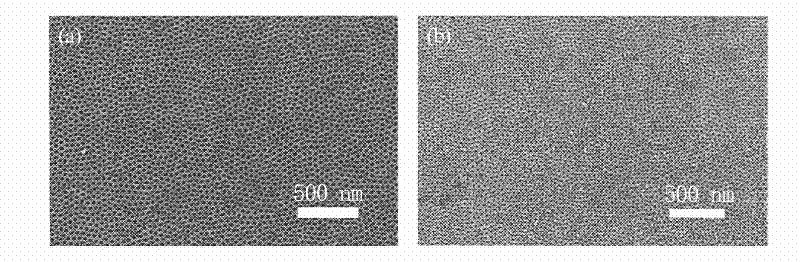

Image

Examples

Embodiment 1

[0025] (1) High-purity aluminum sheet (99.99wt% purity) is annealed at a constant temperature of 500° C. for 4 hours under the protection of an inert gas (such as argon), so as to eliminate the mechanical stress on the surface of the aluminum sheet.

[0026] (2) The aluminum sheet treated in step (1) was ultrasonically cleaned with acetone for 3 minutes and soaked in 1M sodium hydroxide solution for 5 minutes to further remove the grease and oxides present on the surface of the aluminum sheet.

[0027] (3) After the aluminum sheet after step (2) is cleaned with deionized water, it is electropolished at 12V for 5 minutes in the alcohol polishing solution of perchloric acid (the volume ratio of perchloric acid and alcohol is 1: 4) at 5°C, Get a flat and bright aluminum plane.

[0028] (4) The aluminum sheet treated in step (3) was anodized once at 10° C. with 20 V DC constant voltage for 2 hours in 10 wt % sulfuric acid aqueous solution with the aluminum sheet as the cathode.

...

Embodiment 2

[0034] (1) Repeat (1-3) steps in Example 1.

[0035] (2) The aluminum sheet after the above treatment was anodized in 3 wt % oxalic acid aqueous solution, with the aluminum sheet as the cathode at 20° C. and 40 V DC constant voltage for 2 hours once.

[0036](3) The alumina obtained after the treatment in step (2) was immersed in a mixed aqueous solution of 1.8wt% dichromic acid and 6wt% phosphoric acid at 60°C for 40 minutes to remove the oxide layer.

[0037] (4) After the aluminum sheet treated in step (3) was washed with deionized water, it was anodized again under the same conditions as in step (2) for 4 hours.

[0038] (5) After the oxidation in step (4) is completed, step down the voltage by 2V each time until the current is stable until the voltage is 20V, and an anodic aluminum oxide film with an aluminum substrate, regular and orderly pore structure and uniform pore size distribution is obtained. .

[0039] (6) The aluminum oxide film after step (5) is put into the...

Embodiment 3

[0041] (1) Repeat (1-3) steps in Example 1.

[0042] (2) The aluminum sheet after the above treatment was anodized in 10 wt% sulfuric acid solution, using the aluminum sheet as the cathode at 10°C for 3 hours at 10° C. with a constant voltage of 20 V direct current.

[0043] (3) The alumina obtained after the treatment in step (2) was immersed in a mixed aqueous solution of 1.8wt% dichromic acid and 6wt% phosphoric acid at 60°C for 50 minutes to remove the oxide layer.

[0044] (4) After the aluminum sheet treated in step (3) was washed with deionized water, it was anodized again under the same conditions as in step (2) for 4 hours.

[0045] (5) After the oxidation in step (4) is finished, step down the voltage by 2V each time until the current is stable until the current is zero (the voltage is 4V at this time), and the aluminum matrix is obtained and the pore structure is regular and orderly. Uniformly distributed anodized aluminum film.

[0046] (6) The aluminum oxide f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com