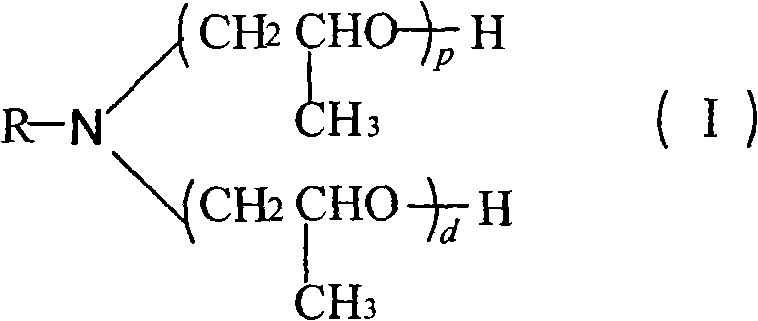

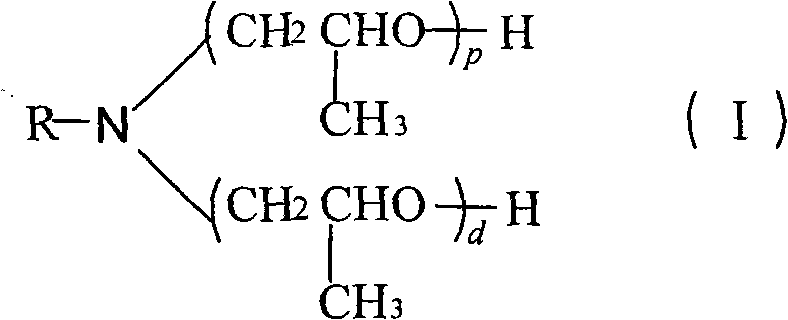

Gasoline detergent prepared by using fatty amine polyoxypropylene ether

A technology for aliphatic amine polyoxypropylene ether and gasoline detergent, which is applied in the petroleum industry, fuel additives, liquid carbon-containing fuels, etc., can solve the problems of lengthy preparation steps, high product cost, high production difficulty and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example 2

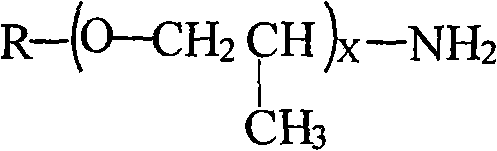

[0029] Preparation of the synthesis reactor: brush the 2L high-pressure reactor with distilled water several times until it is clean, dry the reactor, and lower the temperature to 50-70°C for later use.

[0030] In the first step, 450 g of hexadecylamine was added to the reaction kettle, and after nitrogen replacement twice, the vacuum was drawn while raising the temperature, and when the temperature rose to 130° C., the vacuum valve was closed. Slowly add 180g of propylene oxide, and after the reaction is complete at 135-160°C, cool down to 80°C and discharge.

[0031] The second step: add 370g of the product obtained in the first step and 3.8g of solid KOH into the reactor, heat up to 90-110°C, vacuum dehydrate for 0.5-1.0h, then press 1500g of propylene oxide into the reactor, and control the feeding speed , keep the pressure of the reactor at 0.1-0.5MPa, keep the reaction temperature at 135-160°C, react until the pressure of the reactor no longer drops, cool down to normal...

Embodiment 1

[0033] Laurylamine polyoxypropylene ether obtained in Synthesis Example 1 is compounded with antioxidant, rust inhibitor, corrosion inhibitor and cosolvent, and the mass ratio of each component is: 65.0% laurylamine polyoxypropylene ether , 2.5% T502, 1.5% T747, 1.0% T551 and 30.0% aromatic oil.

[0034] The above-mentioned components are measured according to the ratio to be added, mixed and stirred evenly at room temperature until transparent, and the gasoline detergent of the present invention is obtained after filtration. The gasoline detergent of the present invention is added to commercially available 93# gasoline at a dose of 600 ppm. After evaluation by a professional department, the physical and chemical indicators of the oil product all meet the requirements of GB17930-2006. According to the GB / T19230.4 test method, the decrease rate of deposits generated by the automobile intake valve is simulated, and the change of the deposit increment of the combustion chamber of...

Embodiment 2

[0036] The cetylamine polyoxypropylene ether obtained in Synthesis Example 2 is compounded with antioxidant, rust inhibitor, corrosion inhibitor and cosolvent, and the mass ratio of each component is: 70.0% cetylamine polyoxypropylene ether , 2.5% T502, 1.5% T747, 1.5% T551 and 24.5% aromatic oil. Repeat the preparation method of Example 1 to obtain the gasoline detergent of the present invention.

[0037]The gasoline detergent of the present invention is added to commercially available 93# gasoline at a dose of 700 ppm. After evaluation by a professional department, the physical and chemical indicators of the oil product all meet the requirements of GB17930-2006. According to the GB / T19230.4 test method, the decrease rate of the deposit generated by the automobile intake valve is simulated, and the change of the deposit increment of the combustion chamber of the automobile engine is simulated by a thermogravimetric analyzer. After testing, the sediment reduction rate of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Amine value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com