Membrane adsorbent for removing heavy metal ions from drinking water effectively and preparation method thereof

A technology for heavy metal ion and membrane adsorption, applied in chemical instruments and methods, adsorption water/sewage treatment, water pollutants, etc., can solve problems such as insufficient removal of heavy metal ions, and achieve good adsorption and retention performance and high water permeability , the effect of the simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The present invention has designed the preparation method of described membrane adsorbent simultaneously, and it comprises the steps:

[0035] 1. Preparation of film casting solution: according to the mass percentage requirements of the film adsorbent formula of the present invention, fully mix the various components described, stir at 40-50°C for 4-12 hours, and stand at room temperature for degassing After 5 to 24 hours, a uniformly mixed casting solution is obtained;

[0036] 2. Membrane production: Scrape and coat the prepared casting solution on a flat glass plate to form a flat film, and then soak it in a coagulation bath at 10-80°C for 12-72 hours to make the film solidify and form completely, ensuring that After the residual solvent and additives are removed, the membrane adsorbent with adsorption function can be prepared. The scraping method is manually scraped with a scraper. The thickness of the scraping film or the thickness of the film adsorbent should be...

Embodiment 1

[0045] The mass percentage formula design of the membrane adsorbent casting liquid is: 16wt% polyethersulfone [PES, produced by BASF]; 16wt% macroporous strongly acidic cation exchange resin powder [Nankai University chemical plant, model D061] (polyethersulfone / resin =50 / 50), with an average particle size of 10 μm; 16wt% polyethylene glycol (PEG); 4wt% polyvinylpyrrolidone (PVP) and 48wt% N,N dimethylacetamide (DMAc).

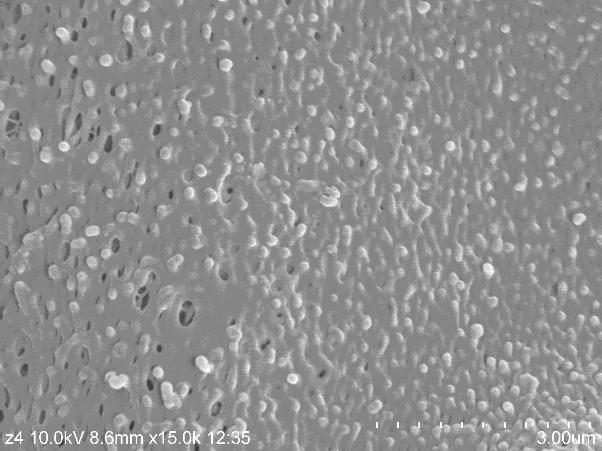

[0046] The process of manufacturing membrane adsorbent is: first add 8g resin to 24gDMAc and stir, after the dispersion is uniform, add 8gPEG and 2gPVP, after the solid is completely dissolved, add 8g PES several times to ensure that the ion exchange resin is dispersed in the polymer Evenly, after adding PES, stir the solution at 50°C for 5 hours; after the dissolution and dispersion are complete, let it stand for defoaming for 24 hours to prepare a casting solution; manually scrape the casting solution at a temperature of 50°C on a glass plate After forming a...

Embodiment 2

[0048] The mass percentage formula design of membrane adsorbent casting solution is: 16wt% polyethersulfone [BASF production]; 13wt% macroporous strongly acidic cation exchange resin powder [Nankai University chemical plant, model D061] (polyethersulfone / resin=55 / 45), with an average particle size of 10 μm; 16wt% ethylene glycol; 4wt% polyvinylpyrrolidone and 51wt% N,N dimethylformamide (DMF).

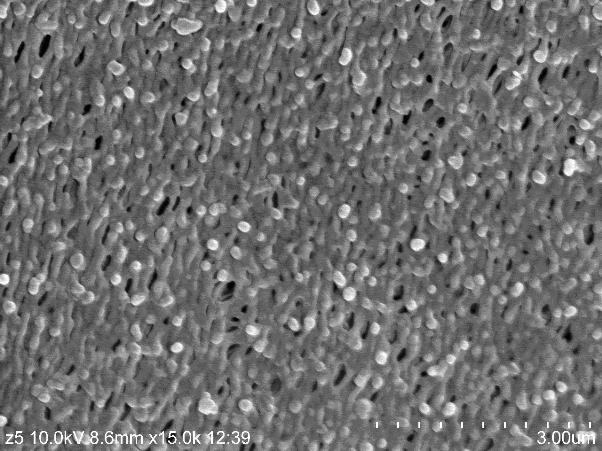

[0049] The process of manufacturing membrane adsorbent is as follows: first add 6.5g resin to 25.5gDMF and stir, after the dispersion is uniform, add 8gEG and 2gPVP, and after the solid is completely dissolved, add 8g PES several times to ensure that the ion exchange resin is in the polymer. After adding PES, the solution was stirred at 50°C for 5 hours; after the dissolution and dispersion were complete, it was left to defoam for 24 hours to prepare a casting solution; the casting solution at a temperature of 20°C was artificially placed on a glass plate After scraping to form a flat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com