Treating agent of a polluted water containing a heavy metal and treating method

A treatment method and technology of treatment agent, applied in water/sewage treatment, adsorption water/sewage treatment, water/sludge/sewage treatment, etc. problem, to achieve the effect of high adsorption efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

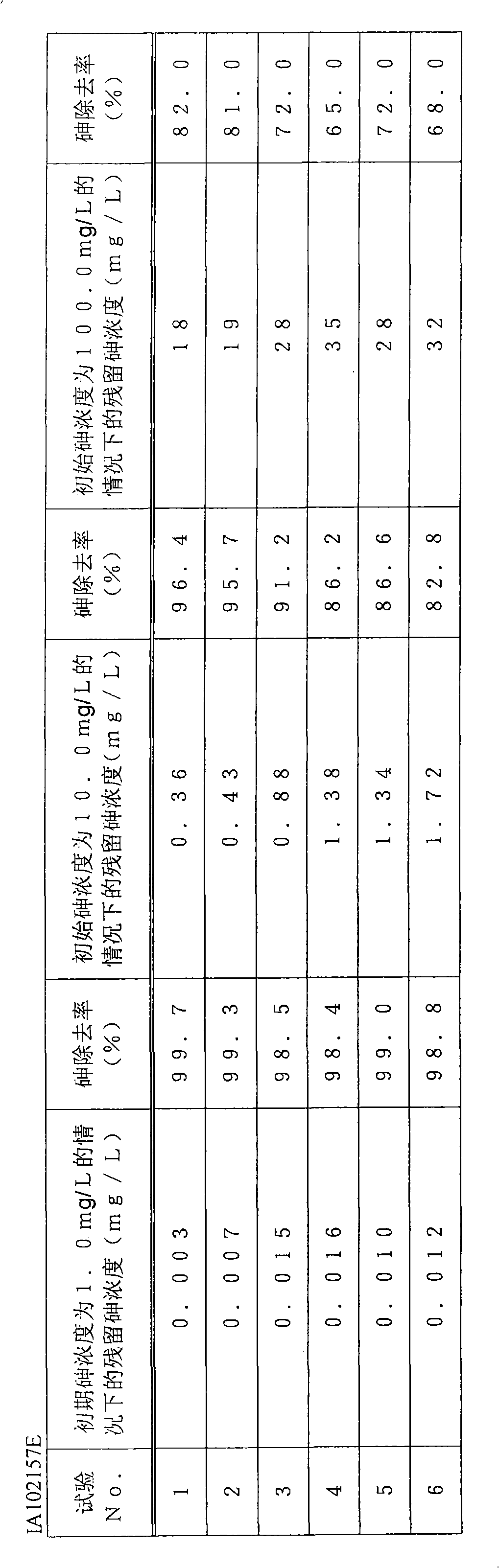

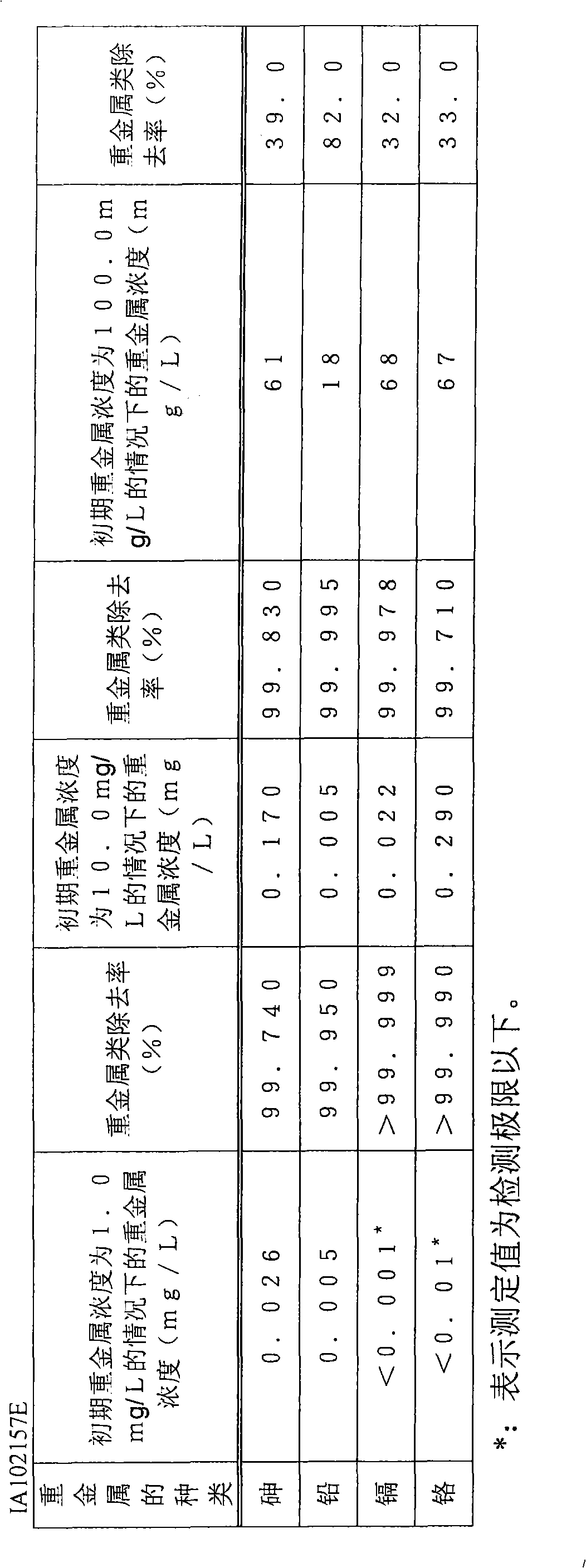

Examples

Embodiment Construction

[0023] The purpose of the treating agent of the present invention is to burn iron powder containing sulfur to form a granular form. The firing method applied in the present invention is useful in obtaining porous particles from the iron powder raw material basically without using a binder. In this method, in order to obtain the above-mentioned particulate matter from the iron powder raw material containing sulfur, for example, the sulfur-containing iron powder obtained by the spraying method is put into a heating furnace in an atmospheric atmosphere or a reducing atmosphere, and heated to at least 900° C. The above temperature can be fired. Thereby, the contact points between the iron powder particles can be firmly fired in the presence of the sulfur component, and a porous and high-strength lump can be obtained. By pulverizing the agglomerate by an appropriate method and classifying with a sieve, particulate matter within a predetermined particle size range can be obtained. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com