Novel material testing machine

A new type of material and testing machine technology, applied in the direction of analyzing materials, measuring devices, instruments, etc., can solve problems such as inability to achieve bidirectional tension, compression, torsion, high use and maintenance costs, and failure to meet experimental requirements. The principle is simple and clear, the cost of equipment is low, and the effect of expanding the scope of application and use occasions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

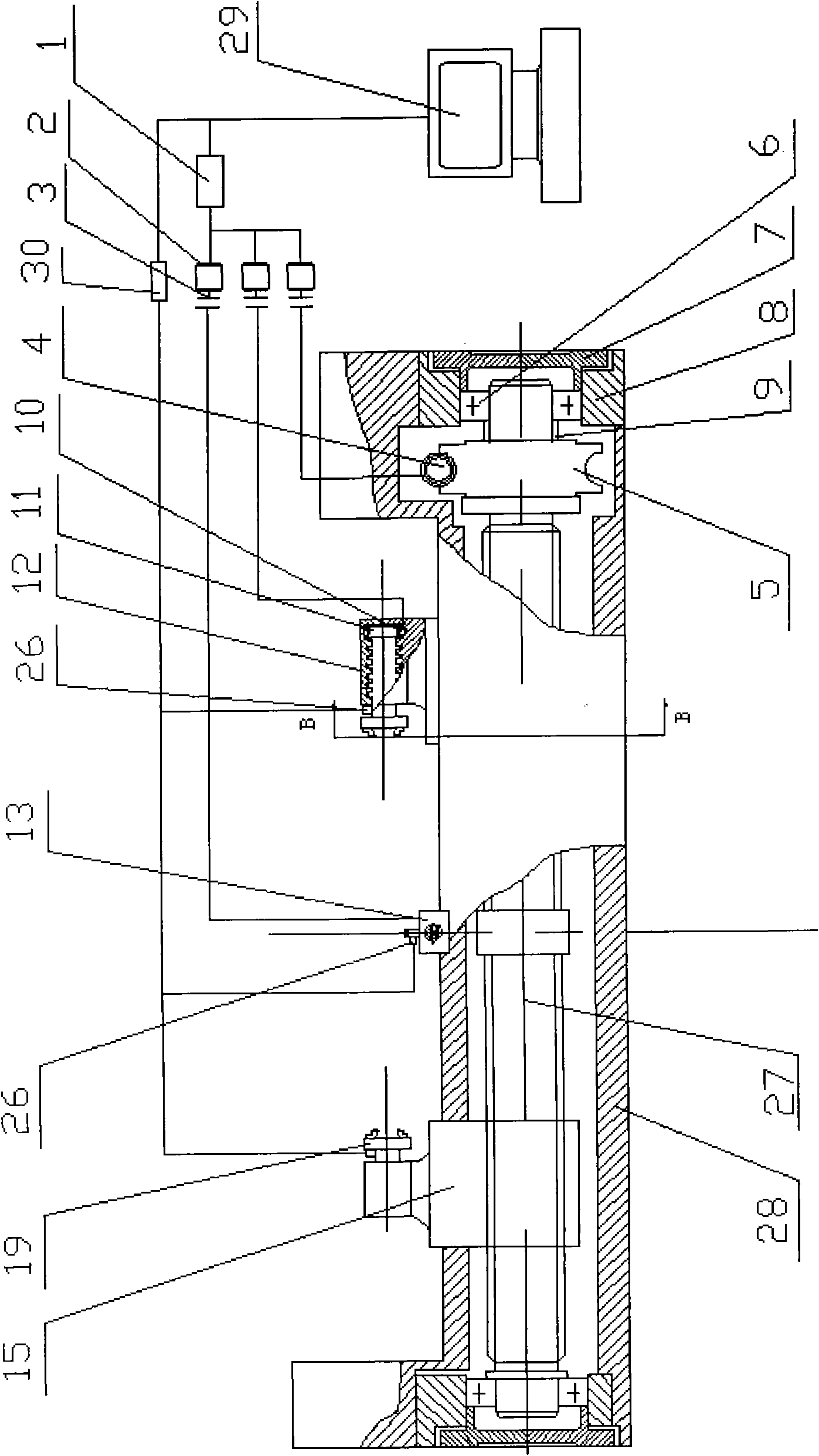

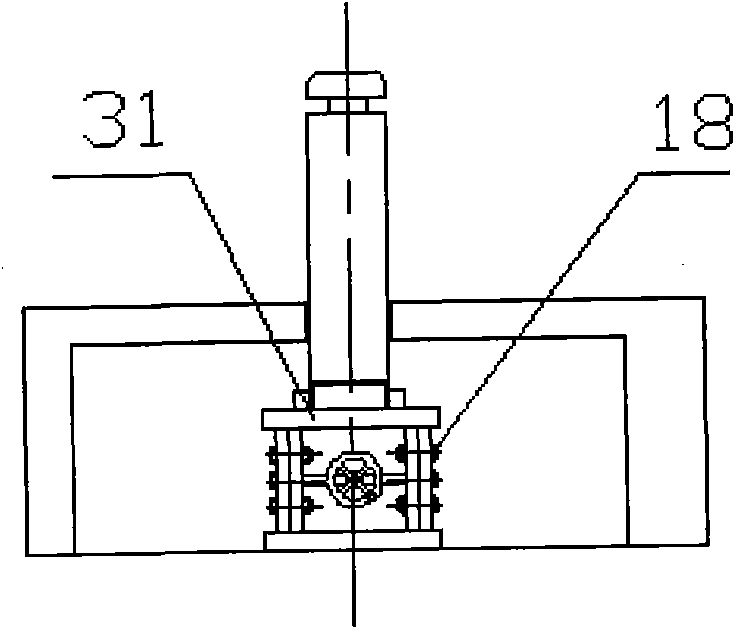

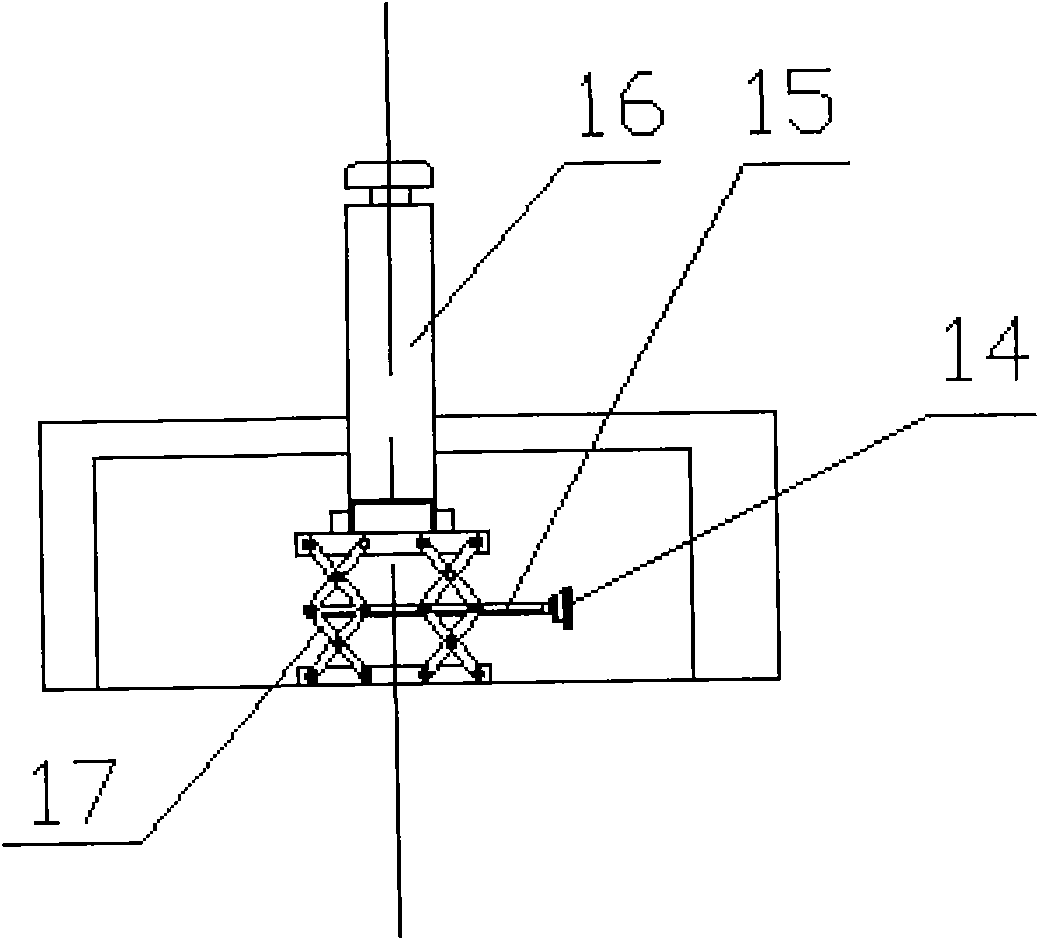

[0030] Said invention consists of figure 1 The overall structure diagram of the material testing machine, figure 2 Front view of bending loading system, image 3 Side view of the bending loading system, Figure 4 Four-jaw chuck front view, Figure 5 The side view of the four-jaw chuck, Figure 9 is a cross-sectional view of the testing machine, which also includes Figure 6 , Figure 7 , Figure 8 Schematic diagram of the specific specimen clamping method. The loading method is divided into automatic control loading and manual control loading.

[0031] The concrete function realization mode of the patent experiment machine of the present invention is as follows:

[0032] 1. Control system: the specific implementation of the control system is by inputting the required realization parameter values on the corresponding program interface of the industrial computer 29, and then the software system sends a control signal to the motion control card 1, and the motion control ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com