Method for recycling low-temperature waste heat from waste incineration fume

A technology of waste incineration and low-temperature waste heat, which is applied in the low-temperature waste heat recovery and utilization of waste incineration flue gas, and the low-temperature waste heat recovery and utilization of flue gas in steel and chemical fields. Waste and other problems, to achieve the effect of good development prospects and promotion value, low operating costs, and strong acid resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Low temperature flue gas conditions after dedusting: temperature 150°C, dust content about 2g / Nm 3 , the flow is about 92881Nm 3 / h, moisture content 31%.

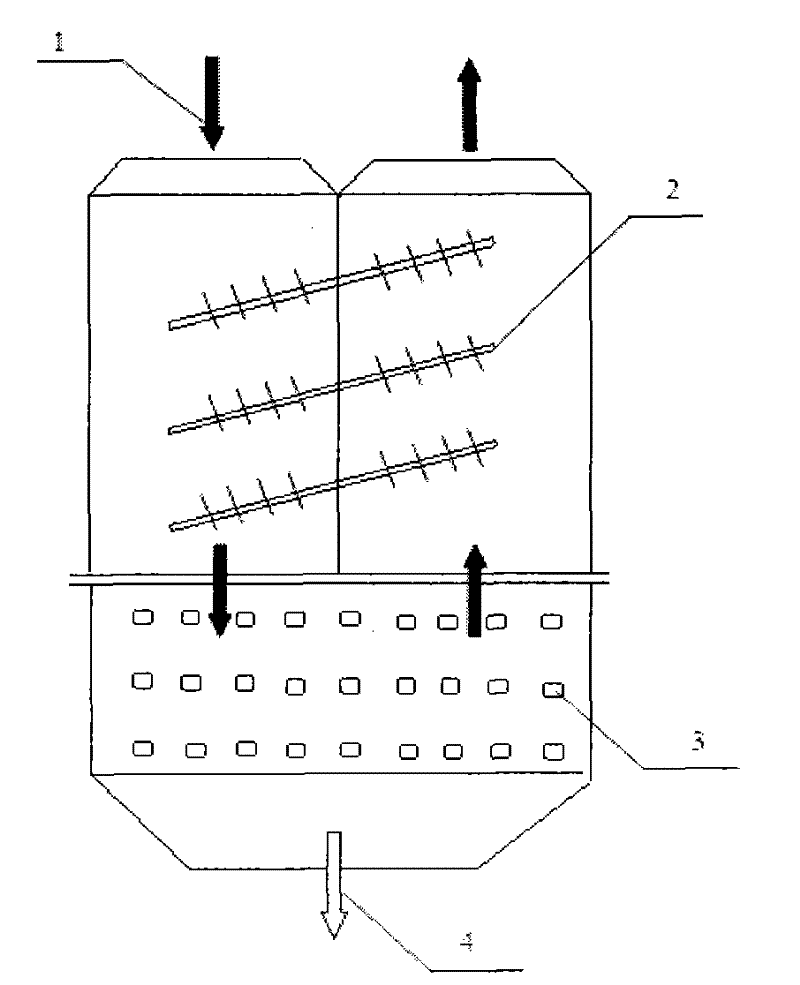

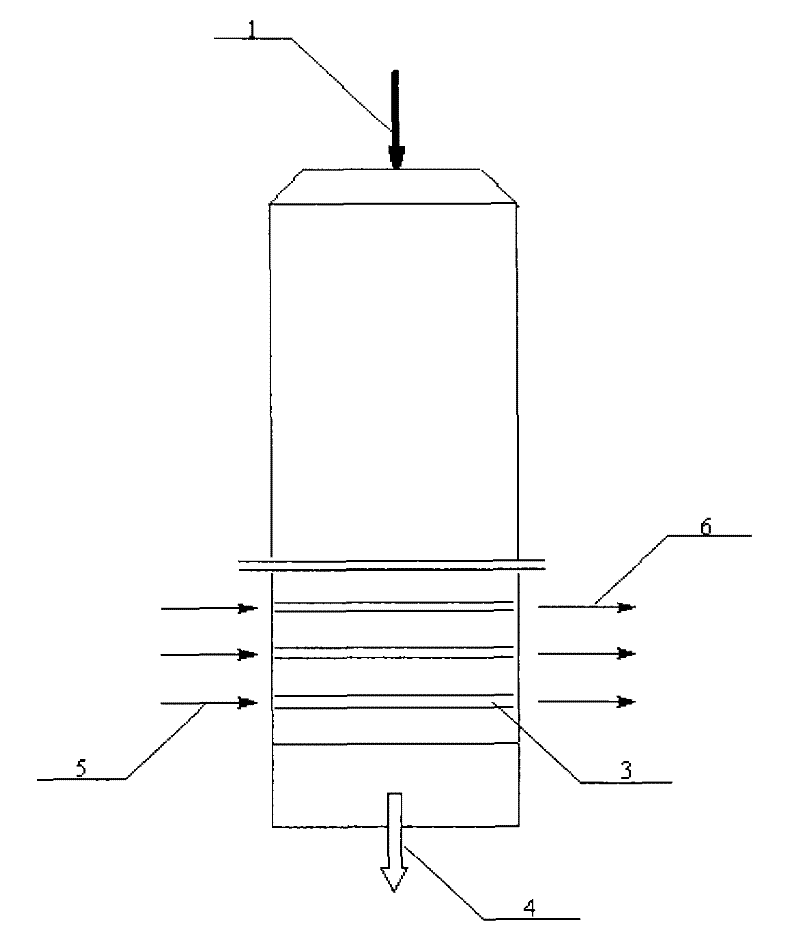

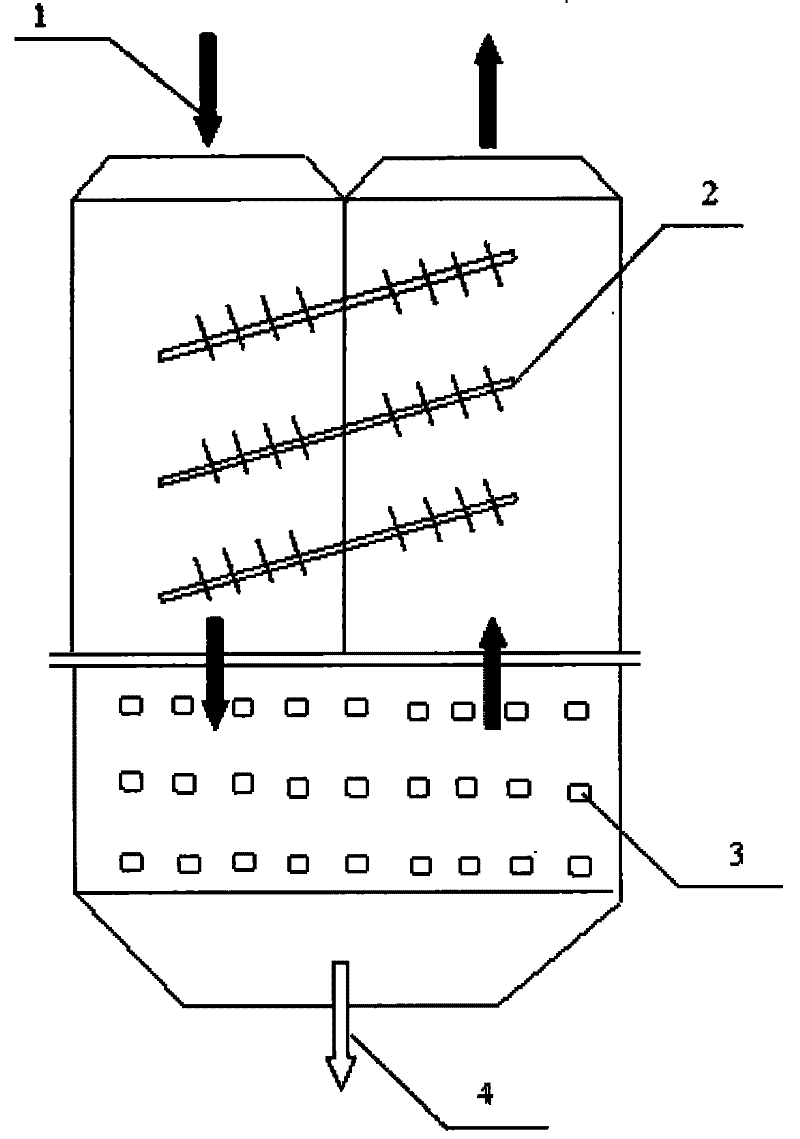

[0021] The low-temperature flue gas 1 after dedusting flows through the whole system in a U shape. On the inlet side, the flue gas 1 first cools down through the heat pipe 2 and then recovers part of the sensible heat. The temperature drops to 120°C, and then enters the shell side of the shell-and-tube condenser tube 3 to lower the flue gas temperature below the dew point temperature, about 34°C. The normal temperature cooling water 5 in the tube side is heated accordingly to obtain hot water 6 . In this process, the total waste heat recovery can reach 13MW, and the flue gas condensate 4 is discharged from the bottom of the equipment. On the outlet side, the low-temperature flue gas passes through the heat pipe 2

[0022] After recovering the sensible heat of the flue gas 1 on the inlet side, the temperature ris...

Embodiment 2

[0025] Low temperature flue gas conditions after dedusting: temperature 160°C, dust content about 1.5g / Nm 3 , the flow is about 113456Nm 3 / h, moisture content 22%.

[0026] The low-temperature flue gas 1 after dedusting flows through the whole system in a U shape. On the inlet side, the flue gas 1 first cools down through the heat pipe 2 and recovers part of the sensible heat, the temperature drops to 135°C, and then enters the shell side of the tube condenser 3 to reduce the flue gas temperature below the dew point temperature, about 50°C. The normal temperature cooling water 5 in the tube side is heated accordingly to obtain hot water 6 . In this process, the total waste heat recovery can reach 10MW, and the flue gas condensate 4 is discharged from the bottom of the equipment. On the outlet side, the low-temperature flue gas recovers the sensible heat of the flue gas 1 on the inlet side through the heat pipe 2, and then the temperature rises again, reaching 90°C, and fin...

Embodiment 3

[0029] Low temperature flue gas conditions after dedusting: temperature 180°C, dust content about 1.8g / Nm 3 , the flow is about 10762Nm 3 / h, moisture content 25%.

[0030] The low-temperature flue gas 1 after dedusting flows through the whole system in a U shape. On the inlet side, the flue gas 1 first cools down through the heat pipe and recovers part of the sensible heat, the temperature drops to 130°C, and then enters the shell side of the tube condenser 3 to lower the flue gas temperature below the dew point temperature, about 59°C. The normal temperature cooling water 5 in the tube side is heated accordingly to obtain hot water 6 . In this process, the total waste heat recovery can reach 8MW, and the flue gas condensate 4 is discharged from the bottom of the equipment. On the outlet side, the low-temperature flue gas recovers the sensible heat of the flue gas 1 on the inlet side through the heat pipe 2, and then the temperature rises again, reaching 85°C, and finally ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com