Reinforced wear-resistance nylon 66 composite for textile apparatuses and preparation method thereof

A technology for textile equipment and composites, which is applied in the field of material science and achieves the effects of high continuous production efficiency, simple process and simple preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1~ example 5

[0033] Nylon 66 is DuPont PA66101L with a viscosity of 2.7±0.05.

[0034] The toughening agent is a mixture of maleic anhydride grafted EPDM rubber and maleic anhydride grafted ethylene-octene copolymer.

[0035] The wear-resistant agent is silicone powder LIYSI-100 from Sichuan Chengdu Silike Technology Co., Ltd. and polytetrafluoroethylene powder PTFE from Shanghai Fluoroplastic Research Institute.

[0036] The 1010 phenolic antioxidant and calcium stearate lubricant selected by Qiba Refining Chemicals as processing aids,

[0037] The glass fiber is the alkali-free fiber of Jushi Group, 988A type, and the number of added parts is controlled by adding the number of glass fiber strands.

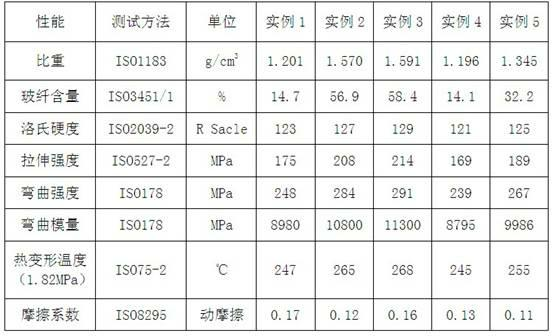

[0038] Weigh each component according to the ratio in the table below in parts by weight.

[0039]

[0040]

[0041] Put the weighed material into the high-speed mixer and mix it for 120~180 seconds at the speed of 600r / min, then add it to the twin-screw extruder for mixing, and add the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com