Sintered permeable environmental-friendly brick produced by using ceramic waste residue and manufacturing method thereof

A technology of ceramic waste slag and environmentally friendly bricks, applied in solid waste management, sustainable waste treatment, climate change adaptation, etc., can solve secondary air pollution, human health hazards, air pollution, etc., to protect the environment and save energy , The effect of improving freeze-thaw resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The waste produced in the production of ceramics and the grinding debris, abrasive grains, bricks and waste water produced in the deep processing and polishing of ceramic products, the sediment obtained from sewage treatment and the added inorganic flocculant are removed by sorting, crushing and magnetic separation After the waste metal is dried, wheel-milled and sieved, it is made into ceramic waste slag powder with a fineness of 30 mesh for use;

[0045] The waste glass fragments, waste glass bottles, waste glass produced in the construction site and home decoration process screened out during the sorting process of domestic waste are crushed, crushed, sorted, magnetically separated, dried, and wheel-milled to powder , After sieving, make waste glass powder with a particle size of 1 mm for use;

[0046] Waste ceramic tiles, waste sanitary ceramics produced in construction site decoration, waste ceramic fragments produced in commercial places and home decoration are pr...

Embodiment 2

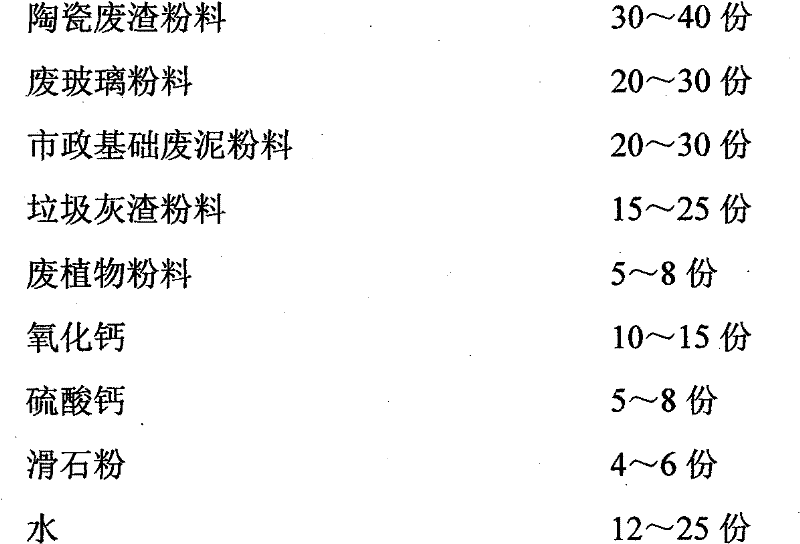

[0052] Get the ceramic waste slag powder 40kg of embodiment 1, waste glass powder 30kg, municipal basic waste mud powder 30kg, garbage ash powder 25kg, waste plant powder 8kg and particle diameter are 0.2mm calcium oxide powder 15kg , calcium sulfate powder 8kg, talcum powder 6kg and water 25kg, add the above-mentioned raw materials into the biaxial mixing mixer and stir to be damp, and then use mechanical vibration to extrude the lower brick of the permeable brick, and then take the above-mentioned prepared waste ceramic fragment powder 30kg, 8kg of bentonite and 4kg of water are evenly mixed, and then a layer of fine fabric is evenly spread on the upper part of the lower brick of the permeable brick with a secondary distributing machine, and then the shaped ceramic waste sintered permeable and environmentally friendly adobe is made under a pressure of 29Mpa and dried naturally. Then the naturally dried ceramic waste sintered permeable environmental protection bricks are sent ...

Embodiment 3

[0054] Get the ceramic waste slag powder 33kg of embodiment 1, waste glass powder 22kg, municipal basic waste mud powder 22kg, garbage ash powder 18kg, waste plant powder 6kg and particle diameter be 12kg of calcium oxide powder of 0.2mm , calcium sulfate powder 6kg, talcum powder 5kg and water 16kg, add the above-mentioned raw materials into the twin-shaft mixing mixer and stir to be moist, and then use mechanical vibration to extrude the lower brick of the permeable brick, and then take the above-mentioned prepared waste ceramic fragment powder 22kg, 6kg of bentonite and 4kg of water are evenly mixed, and then a layer of fine fabric is uniformly spread on the upper part of the lower brick of the permeable brick with a secondary distributing machine, and then the shaped ceramic waste sintered permeable environmental protection brick is made under a pressure of 28Mpa, and then dried naturally. Then the naturally dried ceramic waste sintered permeable environmental protection br...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com