Leakage coaxial cable and manufacturing method thereof

A leaky coaxial cable and outer conductor technology, applied to circuits, electrical components, leaky waveguide antennas, etc., can solve the problems of increased cable production costs, price increases, and shortage of copper resources, and achieve high structural stability and reduced usage , good bending performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

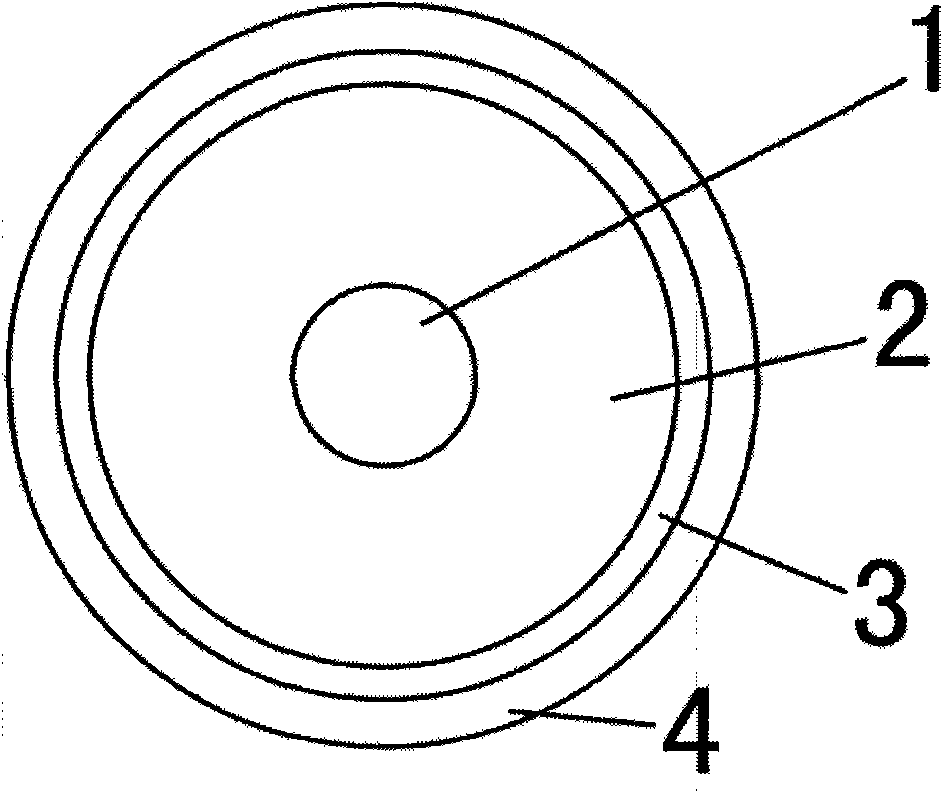

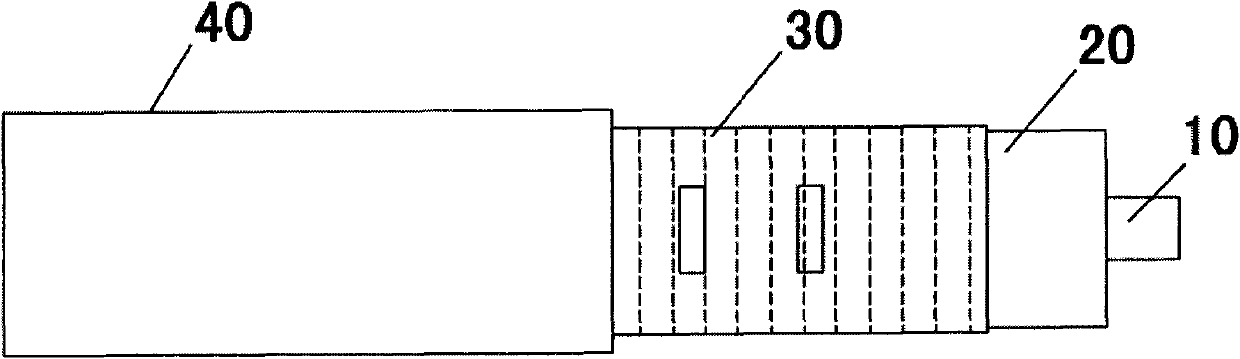

Embodiment 1

[0027] In this embodiment, the inner conductor 1 is folded copper tube, the insulating layer 2 is physical foamed polyethylene with high foaming degree, the sheath layer 4 is made of halogen-free flame-retardant polyethylene, and the outer conductor 3 is a self-adhesive structure. Smooth grooved copper-plastic composite tape. The thickness of the smooth slotted copper-plastic composite tape with self-adhesive structure is 0.08mm, and the thickness of the copper base tape is 0.04mm. Compared with the existing products, the actual amount of copper used in the leakage coaxial cable of this embodiment is only the original 40% (calculated on the basis that the thickness of the pure copper strip of the existing leaky coaxial cable is 0.1 mm), effectively reducing the amount of copper used and saving costs.

[0028] After longitudinally wrapping the smooth slotted copper-plastic composite tape with self-adhesive structure on the insulating layer 2, extruding to form the sheath layer ...

Embodiment 2

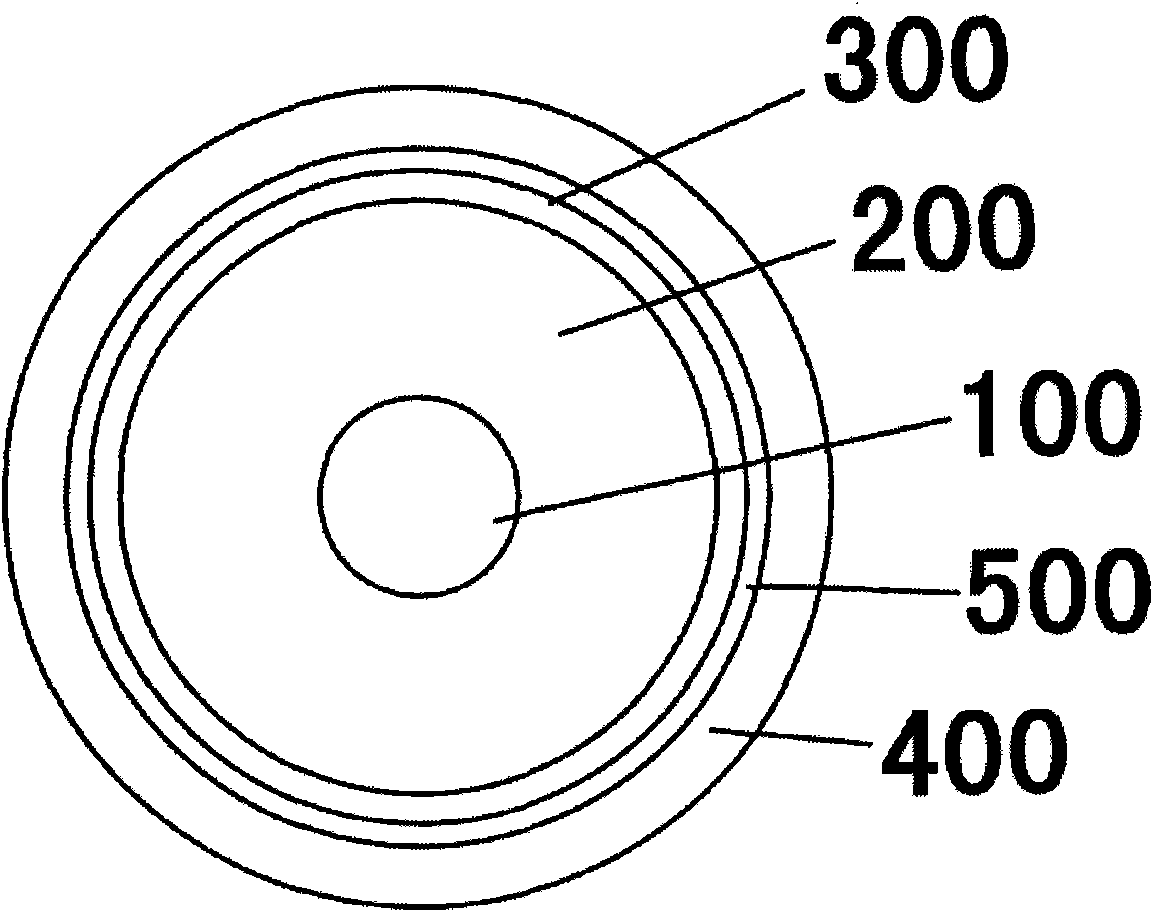

[0030] This embodiment is basically the same as the leaky coaxial cable described in Embodiment 1, and will not be described in detail here for simplicity. The difference between embodiment 2 and embodiment 1 is that the inner conductor 1 is a smooth copper tube, and the thickness of the smooth grooved copper-plastic composite tape with self-adhesive structure adopted by the outer conductor 3 is 0.06 mm, and the thickness of the copper base tape is 0.02 mm. mm, compared with existing products, the actual amount of copper used in the leaky coaxial cable of this embodiment has only 20% of the original (calculated with the pure copper strip thickness of the existing leaky coaxial cable as 0.1mm), which also effectively reduces The amount of copper used is reduced and the cost is saved.

[0031] The leaky coaxial cable of the present invention has high structural stability and good bending performance. At the same time, due to the use of metal foil with self-adhesive structure, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com