Checking platform and checking method for resetting and maintenance training of intelligent numerical control machine

A CNC machine tool and intelligent technology, applied in teaching models, educational tools, instruments, etc., can solve the problems of easily damaged equipment components, low efficiency, inconvenient use, etc., to reduce the probability of miswiring and improve the efficiency of assessment High, easy switching effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

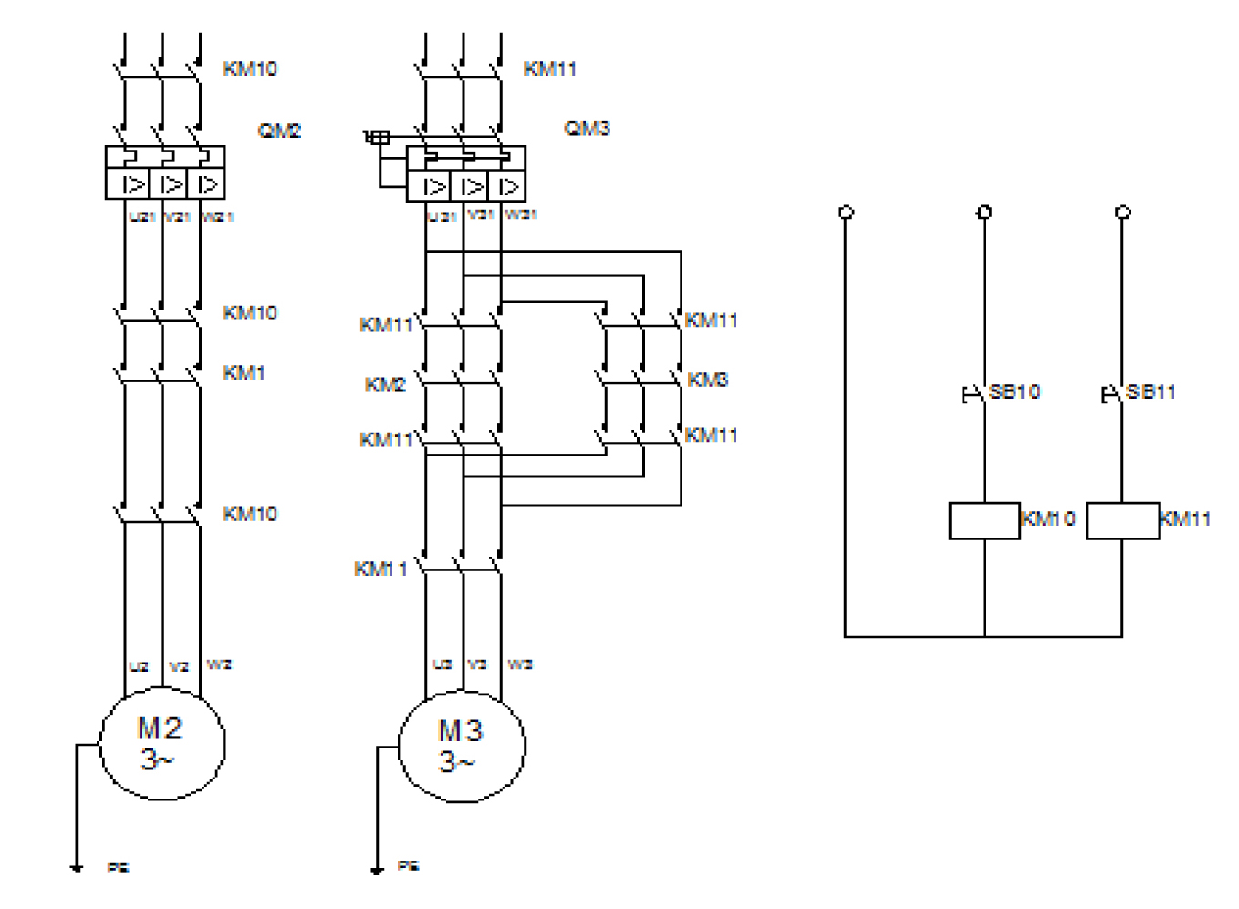

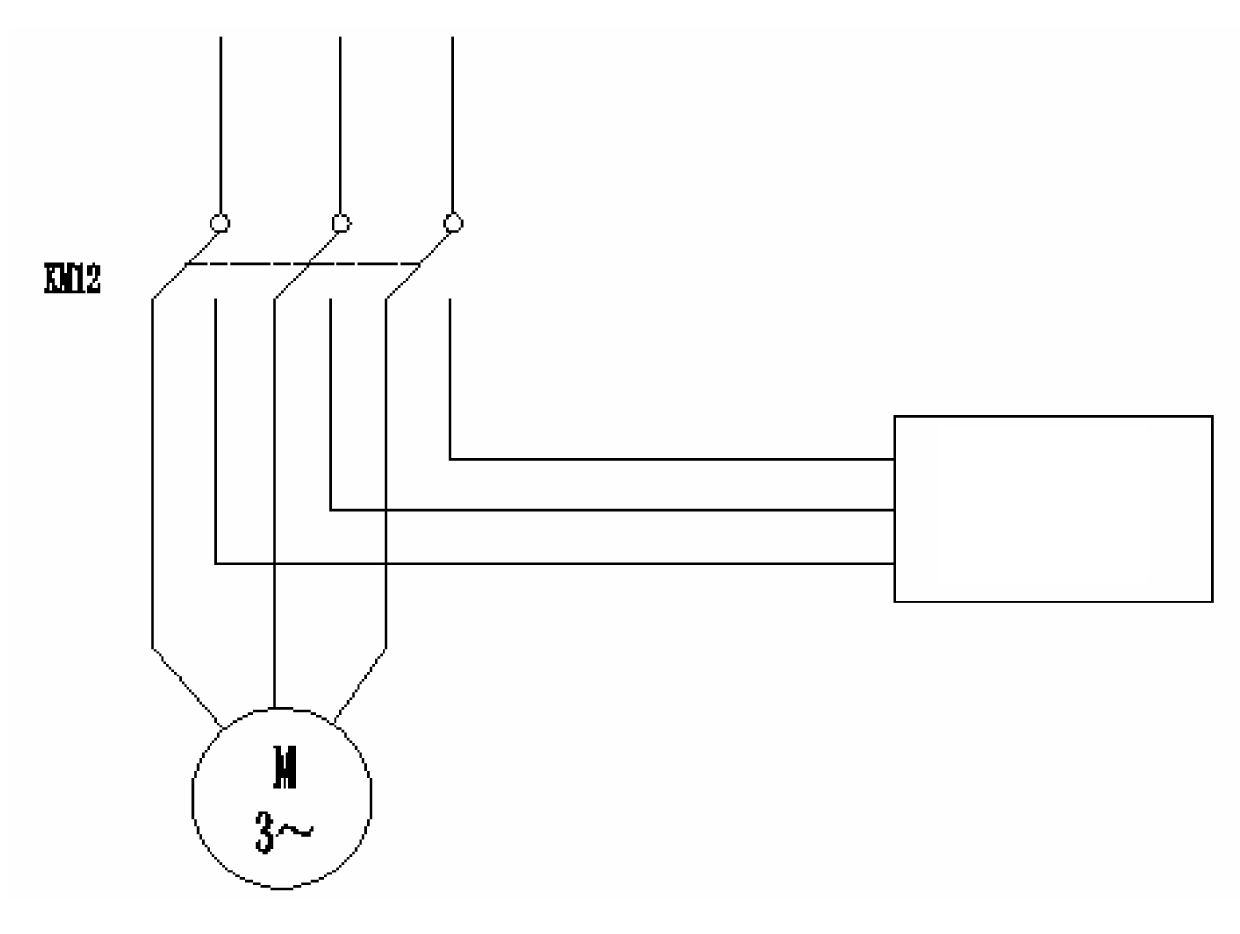

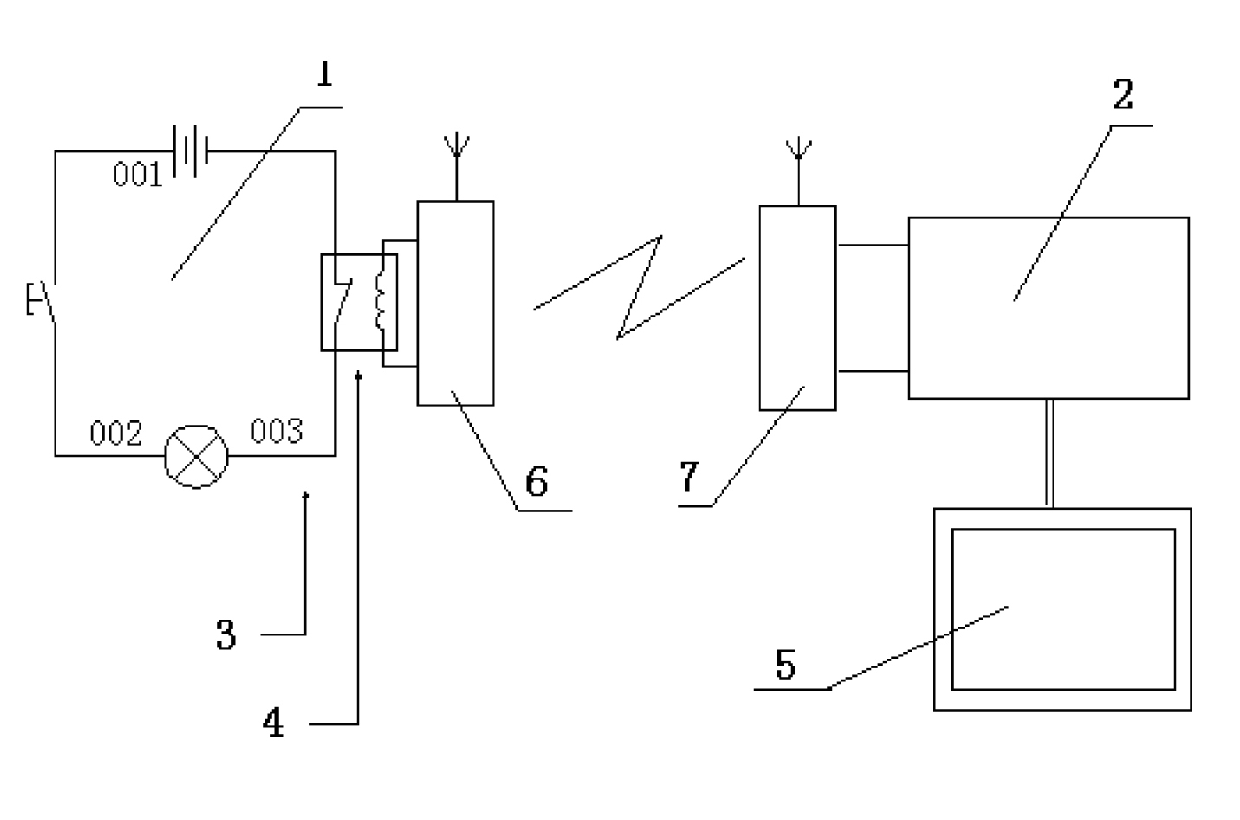

[0032] refer to figure 1 , an intelligent CNC machine tool assembly and maintenance training assessment platform, including an assessment circuit 1 and an assessment system 2, the assessment circuit 1 includes a controllable switch fault point 3, and the assessment system 2 includes a computer 5, and the computer 5 Real-time control of the setting and closing of the fault point 3 of the controllable switch, and detection of the elimination status of the fault point 3, and real-time statistical evaluation.

[0033] Further as a preferred embodiment, the controllable switch fault point 3 of the assessment circuit 1 is connected to a wireless receiving system 6, and the computer 5 of the assessment system 2 is connected to a wireless transmitting system 7, and the wireless transmitting system 7 is connected to the The wireless receiving system 6 wirelessly connects and communicates.

[0034] As a further preferred embodiment, the computer is a touch screen computer.

[0035] Fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com