Long segmental structure of offshore high-piled wharf

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

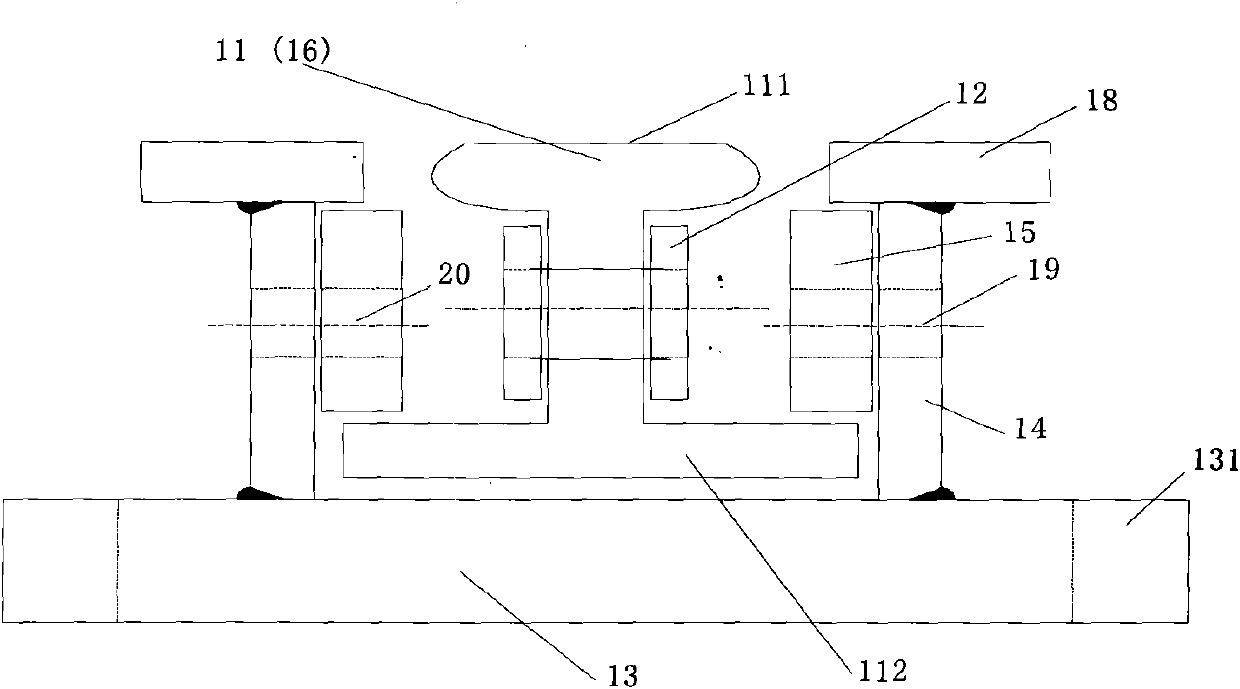

[0052] In order to make the technical means, creative features, goals and effects of the present invention easy to understand, the present invention will be further elaborated below in conjunction with the specific diagrams for the long segmental structure characteristics of the high-pile wharf.

[0053] 1. Calculation of the longitudinal internal force of the wharf structure under the action of annual weather temperature difference deformation, shrinkage deformation and prestress creep of concrete.

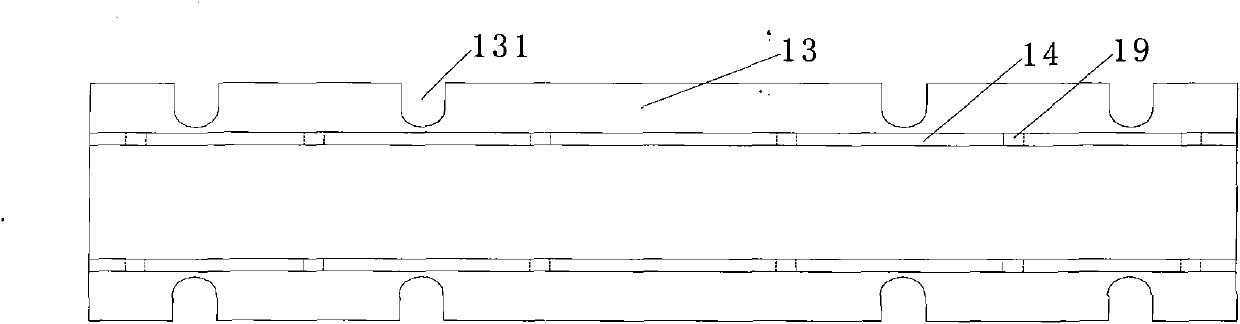

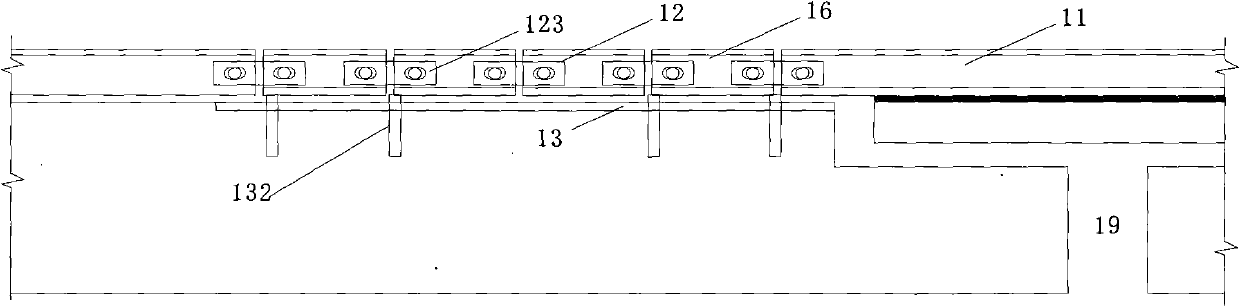

[0054] 2. Pile foundation layout of long section wharf.

[0055] 3. The distribution of the horizontal force of the long section wharf in each bent frame.

[0056] 4. Simplified calculation method for the design of long section wharves.

[0057] 5. The key points of the design and construction of the long section wharf.

[0058] 6. Track machinery and other mobile machinery can smoothly transition to expansion joints.

[0059] The following elaborates on the above issues:

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com