Wind turbine blade with lift-regulating means in form of slots or holes

一种风力涡轮机、调节装置的技术,应用在与风向一致的的风力发动机、风力发动机、风力发动机的控制等方向,能够解决液压技术不适于快速且几乎瞬时的运动、风力涡轮机不能特别快地进行调整等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

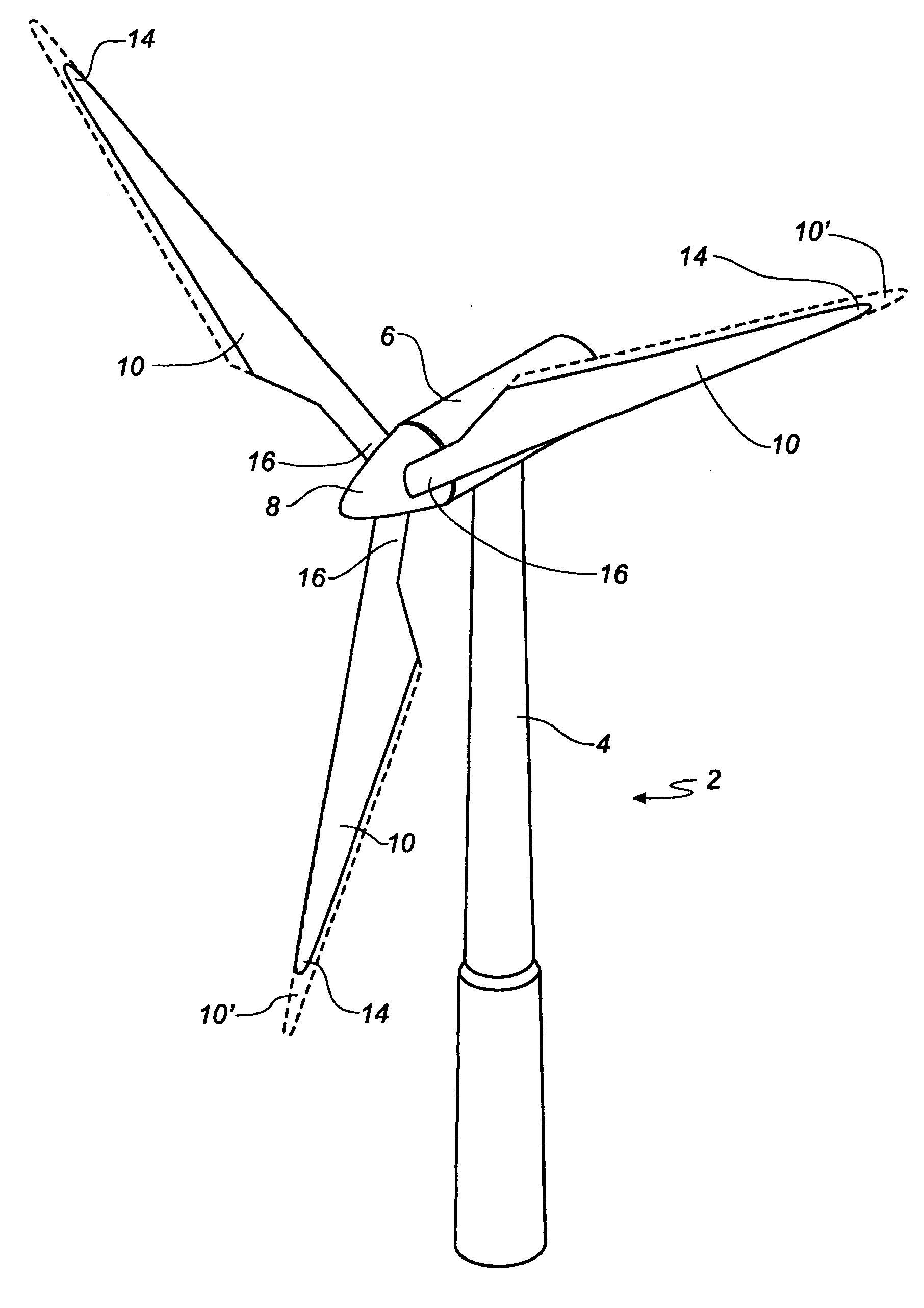

[0043] figure 1 A conventional modern wind turbine is shown having a tower 4 , a nacelle 6 and a rotor comprising a hub 8 and three blades 10 extending from the hub 8 . The blade 10 may be provided with a lift regulating device which can gradually reduce the blade lift in a region extending from the blade tip 14 to a position between the blade tip and the blade root 16 at high wind speeds by activating the actuating device. As a result, at high wind speeds, the blade 10 is unloaded in the region extending inwardly from the blade tip 14 towards the root 16, so that a wind turbine 2 with a given blade 10 can still operate at higher wind speeds than usual. The invention also makes it possible to provide a wind turbine 2 with longer blades 10' than usual, which at increased wind speeds and thus under increased loads are only unloaded by the lift regulating means, so that the turbine and the blades are overloaded be avoided.

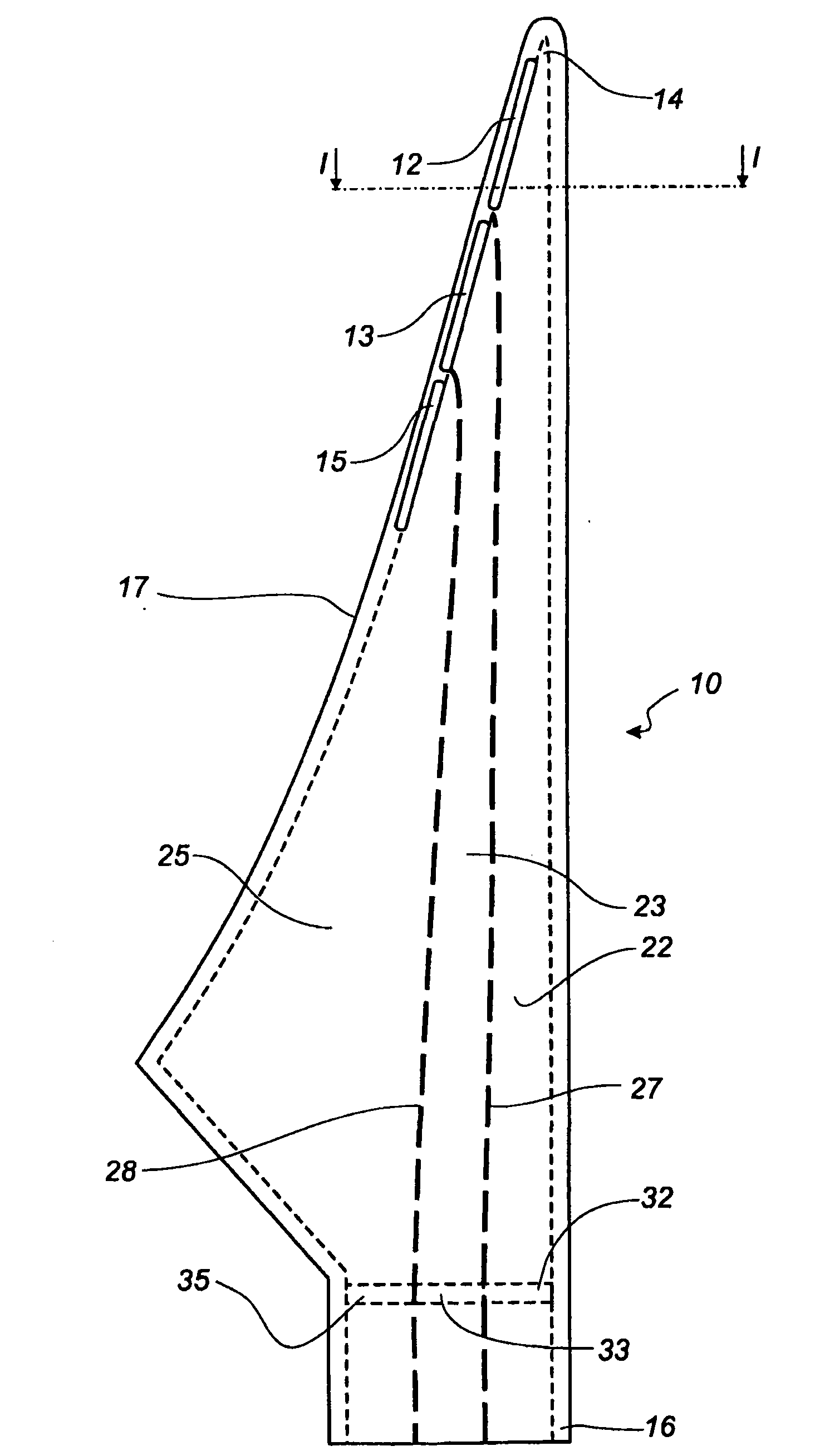

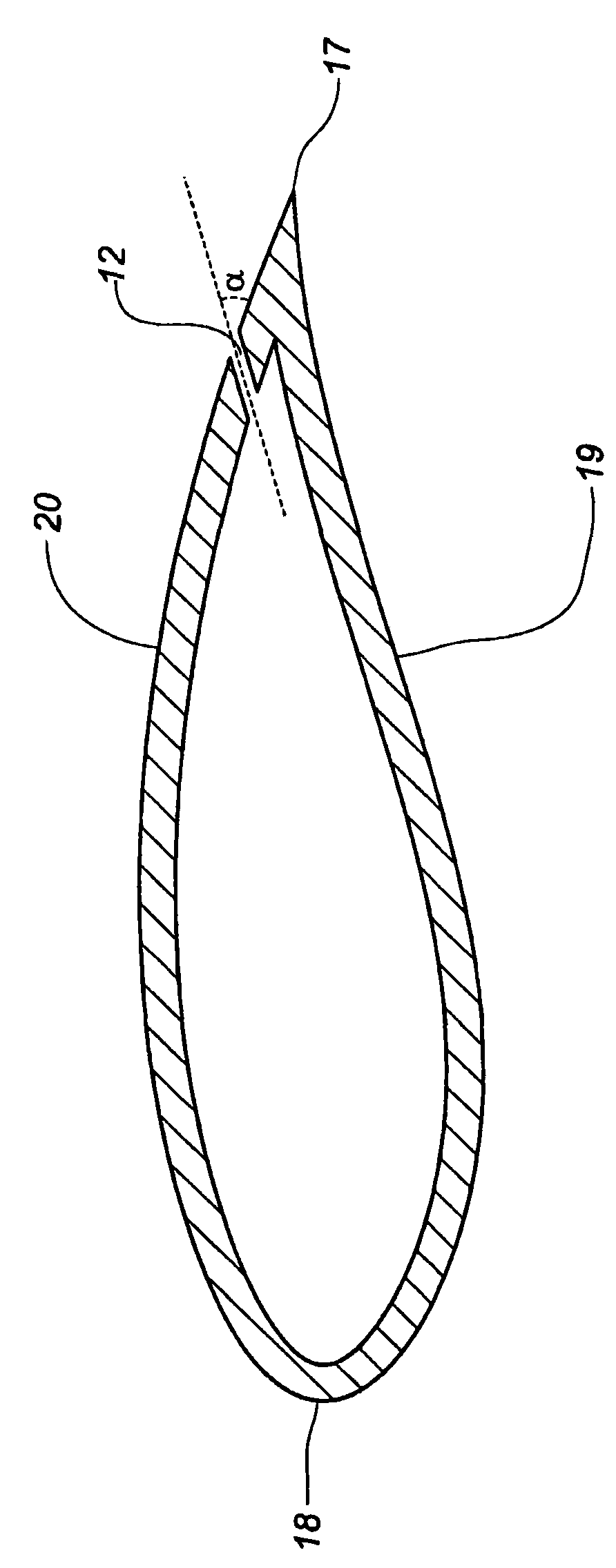

[0044] figure 2 A schematic diagram showing a first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com