Novel platinum alloy electrical contact material and preparation method thereof

An electrical contact material, platinum alloy technology, applied in the field of metal materials, can solve the problems of serious arc erosion crater on the contact surface, unrealizable, early failure of contact devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The preparation method of the platinum alloy of the present invention comprises the following processing steps in sequence:

[0019] (1) Select alloy raw materials with purity >99.99%, design formula requirements according to alloy chemical composition, alloy in vacuum intermediate frequency or high frequency melting furnace, vacuum degree: >1×10 -3 Pa;

[0020] (2) After the superheated temperature of the melt reaches 200°C-300°C, vacuum casting is carried out into plates or rods. The size of the plate is ≠5-10mm×30-50mm, the size of the bar is Φ6mm-Φ10mm, and the cooling rate of the melt is>1×10 4 K / s.

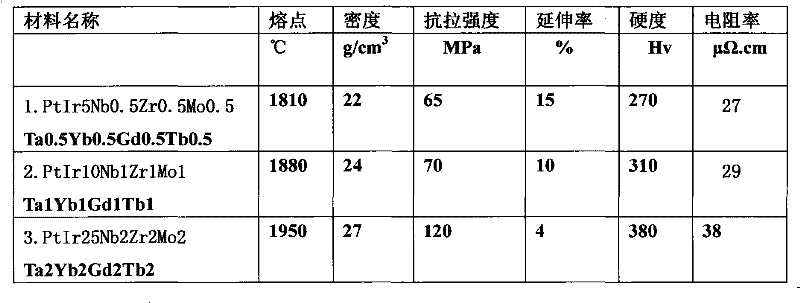

[0021] (3) The final preparation of PtIrNbZrMoTaYbGdTb multi-element rare metal alloy material

[0022] (4) The weight of the alloy ingot is 100g ~ 1000g;

[0023] (5) The alloy is prepared into finished products in the shape of plates, rods or contacts through rolling, drawing, heat treatment and other processes.

[0024] The specific implementation of the novel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com