Method for preparing antihypertensive peptides by using enzymatic degradation on mussel-digested protein

A technology of hypotensive peptides and mussels, applied in the field of bioengineering, can solve the problems of low activity of antihypertensive peptides ACE inhibitory peptides, etc., and achieve the effects of strong industrial implementation, improved utilization, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

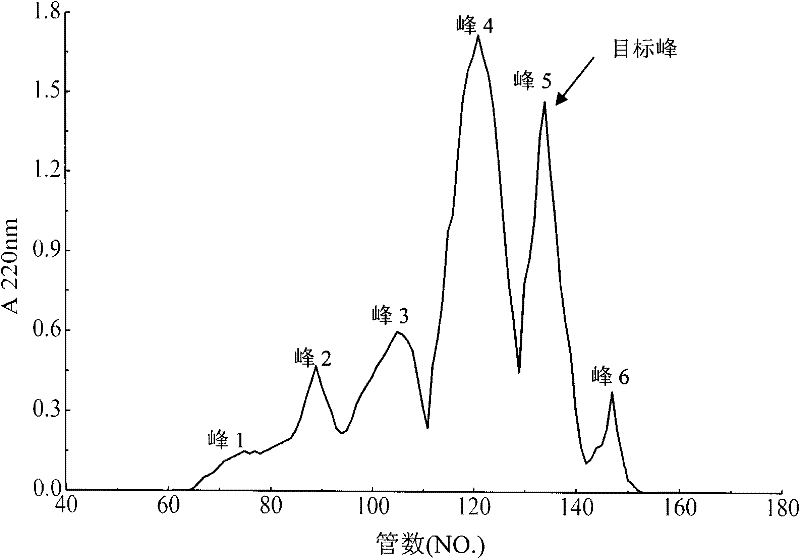

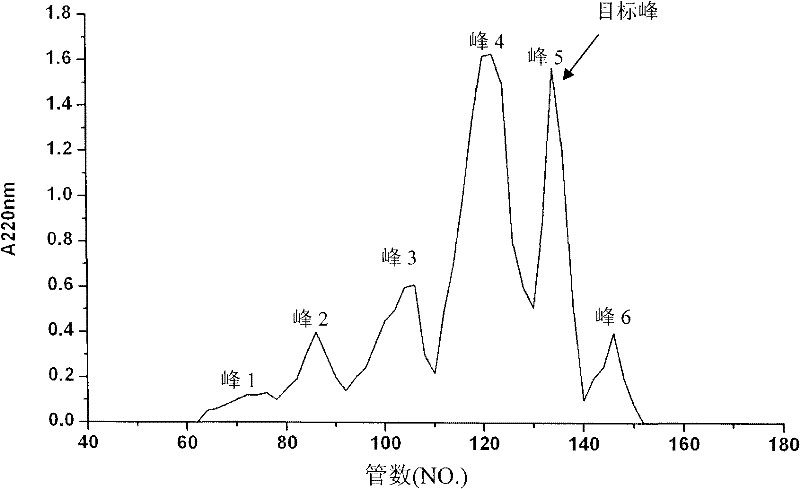

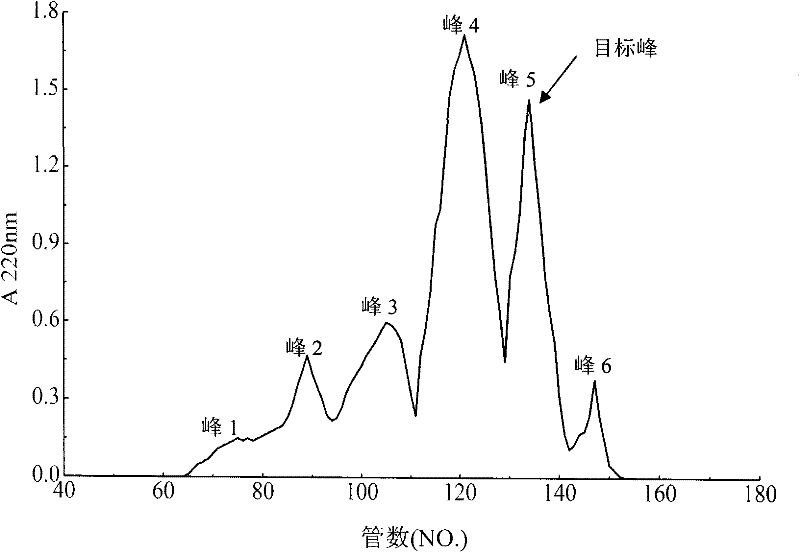

Image

Examples

Embodiment 1

[0043] Embodiment 1. A method for enzymatically hydrolyzing mussel protein to prepare hypotensive peptides, the following steps are performed in sequence:

[0044] 1), prepare defatted dry mussel powder:

[0045] Wash the fresh blue mussels with water, shell and remove the silk, homogenize them with a beater until they are paste, freeze-dry (-50°C, 72 hours) to obtain mussel powder. Add the mussel powder at 40°C to degrease the ethanol solution with a volume concentration of 95% in the ratio of 1g:4ml for 4h, repeat three times; vacuum-dry the above-mentioned degreased mussel powder at 40°C (5 hours), pulverize And pass through a 100-mesh sieve to obtain defatted dried mussel powder with a moisture content of ≤2.34%.

[0046]2) Weigh 5.0 g of the above degreased dried mussel powder (protein weight content 60.23%) in the enzyme reactor, add 100 ml of deionized water and stir evenly, homogenize for 10 min, adjust the pH to 9.2 with 0.5 mol / L NaOH solution ; A mixture was obtai...

Embodiment 2

[0058] Embodiment 2, a method for enzymatically hydrolyzing mussel protein to prepare hypotensive peptides, the following steps are carried out in sequence:

[0059] 1), prepare defatted dry mussel powder:

[0060] Replace fresh blue mussel with fresh thick shell mussel, all the other are the same as embodiment 1.

[0061] 2) Weigh 5.0 g of defatted dried mussel powder (protein weight content 72.56%) into the enzyme reactor, add 100 ml of deionized water and stir evenly, homogenize for 10 min, and adjust the pH to 9.2 with 0.5 mol / L NaOH solution; Get a mixture.

[0062] 3), the temperature of the mixed solution was raised to 60° C., stirred and preheated, and kept under stirring for 20 minutes; 4 U / g) to start the enzymolysis reaction, the enzymolysis temperature is 60-65°C, stirring continuously, keeping the temperature and pH of the reaction system constant, and the enzymolysis time is 240 minutes. Obtain enzymatic hydrolysis products.

[0063] 4) The enzymatic hydrolyz...

Embodiment 3

[0073] Embodiment 3, a method for enzymatically hydrolyzing mussel protein to prepare hypotensive peptides, the following steps are carried out in sequence:

[0074] 1), prepare defatted dry mussel powder:

[0075] With embodiment 1.

[0076] 2) Weigh 200.0 g of defatted dried mussel powder (protein weight content 60.23%) into the enzyme reactor, add 5 L of deionized water and stir evenly, homogenize for 10 min, and adjust the pH to 9.3 with 0.5 mol / L NaOH solution; Get a mixture.

[0077] 3), the temperature of the mixed solution was raised to 65° C., stirred and preheated, and kept under stirring for 20 minutes; 4 U / g) to start the enzymolysis reaction, the enzymolysis temperature is 65°C, the temperature and pH of the reaction system are kept constant, and the enzymolysis time is 180 minutes with continuous stirring. Obtain enzymatic hydrolysis products.

[0078] 4) The enzymatic hydrolyzate obtained in step 3) is firstly treated with enzyme inactivation to obtain an en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com