Method for preparing electrolytic manganese slag ecological cement

A technology of electrolytic manganese slag and ecological cement, which is applied in the fields of building materials and environmental protection, can solve problems such as ecological damage and environmental pollution, and achieve the effects of reducing serious damage, good environmental and economic benefits, and high product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] A composition and preparation method of electrolytic manganese slag ecological cement, the method preparation steps are:

[0017] (1) First crush the electrolytic manganese slag into 1-10mm fragments with a crusher, and then calcinate at 700°C;

[0018] (2) Mix 30% blast furnace slag and 20% clinker and grind to a specific surface area of 420m 2 / kg, and then mixed with crushed and calcined electrolytic manganese slag 35%, fly ash 9%, gypsum 5% and additive 1%, the final mixture should be ground to a specific surface area of 510m 2 / kg.

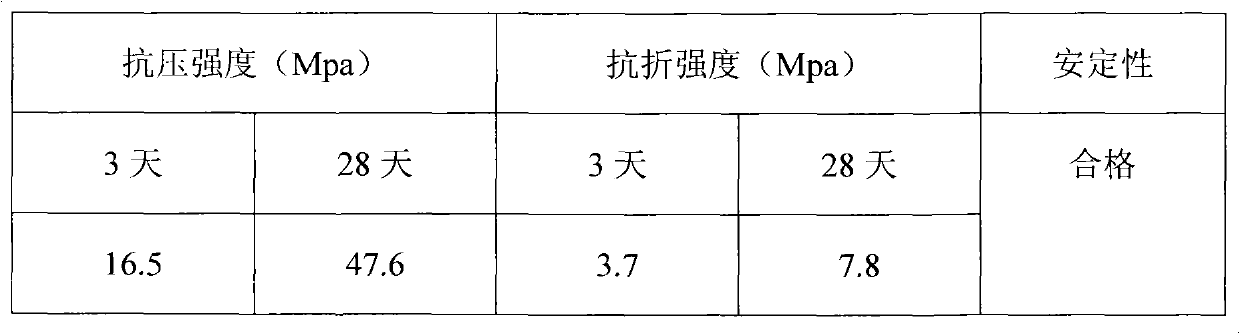

[0019] (3) Finally, after the various powders obtained in step (2) are tested, they can be used as ecological cement products. The properties that can be achieved by testing the strength and stability of the material according to the GB175-2007 standard are shown in Table 1.

[0020] The basic properties of the product obtained in Table 1 Example 1

[0021]

Embodiment 2

[0023] A composition and preparation method of electrolytic manganese slag ecological cement, the method preparation steps are:

[0024] (1) First crush the electrolytic manganese slag into 1-10mm fragments with a crusher, and then calcinate at 800°C;

[0025] (2) Mix 40% of blast furnace slag and 10% of clinker and grind until the specific surface area is 410m 2 / kg, and then mixed with crushed and calcined electrolytic manganese slag 40%, fly ash 5%, gypsum 4% and additive 1%, the final mixture should be ground to a specific surface area of 510m 2 / kg.

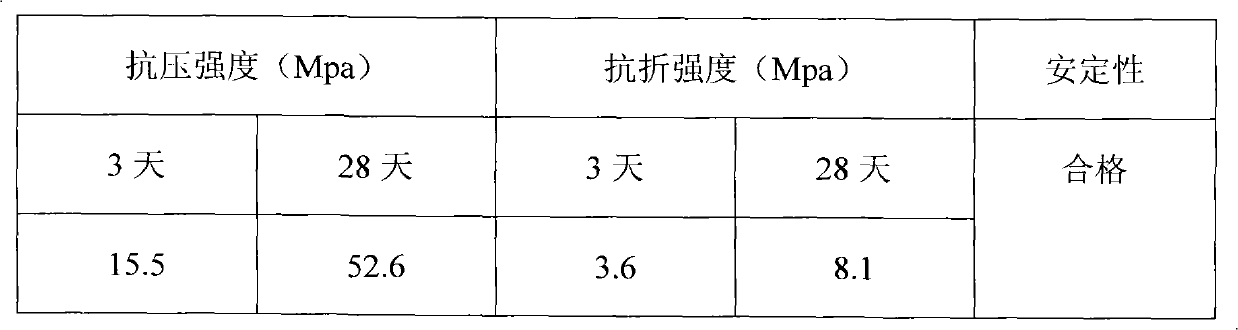

[0026] (3) Finally, after the various powders obtained in step (2) are tested, they can be used as ecological cement products. The properties that can be achieved by testing the strength and stability of the material according to the GB175-2007 standard are shown in Table 2.

[0027] Gained product basic performance in the embodiment 2 of table 2

[0028]

Embodiment 3

[0030] A composition and preparation method of electrolytic manganese slag ecological cement, the method preparation steps are:

[0031] (1) First crush the electrolytic manganese slag into 1-10mm fragments with a crusher, and then calcinate at 750°C;

[0032] (2) Mix and grind 35% of crushed and calcined electrolytic manganese slag, 30% of blast furnace slag, 15% of clinker, 15% of steel slag, 3% of gypsum and 2% of additive, and the final mixture is ground to a specific surface area of 480m 2 / kg.

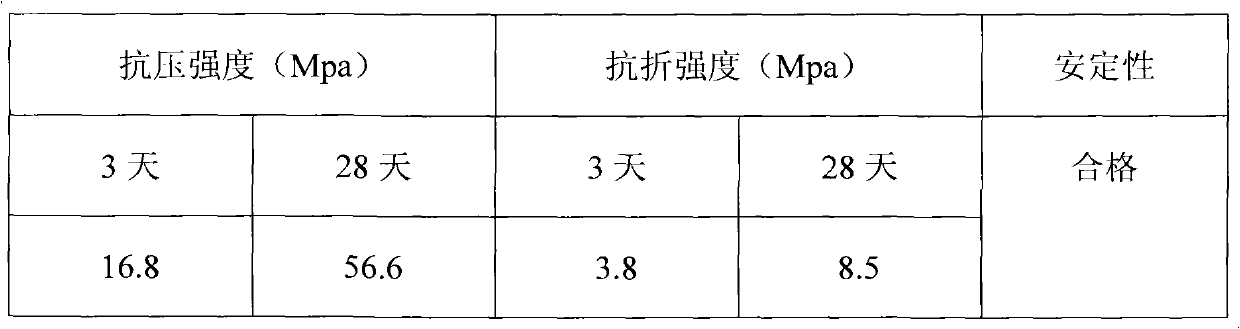

[0033] (3) Finally, the mixture obtained in step (2) can be used as an ecological cement product after inspection. The performance of the material that can be tested for strength and stability according to the GB175-2007 standard is shown in Table 3.

[0034] The basic properties of the product obtained in Table 3 Example 3

[0035]

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com