Hole-rolling knife

A hole cutter and cutter sleeve technology, which is applied in the field of tools for rolling round hole walls, can solve the problems of poor pressure bearing capacity, abnormal noise, easy rotation of the bearing outer ring, etc., and achieves high smoothness, convenient use and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

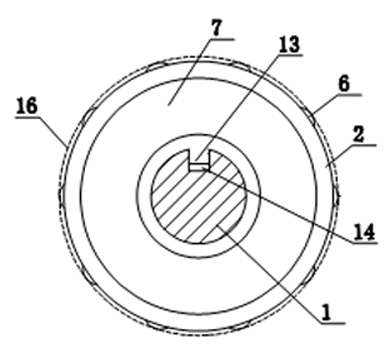

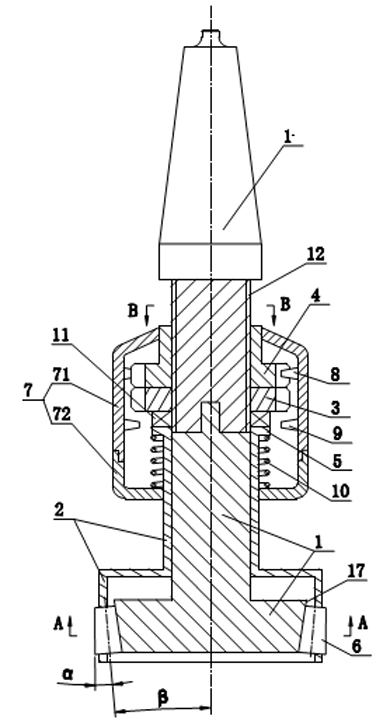

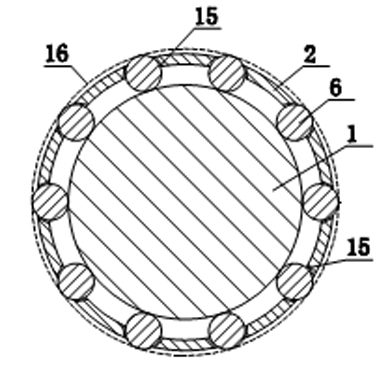

[0014] like figure 1 , figure 2 and image 3 As shown, the hobbing cutter includes a tool bar 1 and a tool holder 2, and an external thread 12 is provided on the middle section of the tool bar 1. The tool bar 1 is screwed with an adjusting gear 3 through the external thread 12, and an adjusting gear 3 is provided above the adjusting gear 3. The locking gear 4 whose upper end surface is in contact and can only slide axially. The locking gear 4 cooperates with the sliding key 13 fixed in its inner hole and the chute 14 provided on the cutter bar 1 to realize that the locking gear 4 can only Slide along the axial direction of the tool holder 1. The knife cover 2 is looped on the cutter bar 1 and the two are arranged concentrically. The meaning of the looper is that the knife cover 2 can rotate and slide, and a thrust bearing 11 is provided between the knife cover 2 and the adjusting gear 3 . The upper end of the knife cover 2 is provided with a shoulder 5, and the outer surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com