Production technology for inhibiting nickel-saving austenitic stainless steel hot-rolled plate edge crack

A production process, stainless steel technology, applied in manufacturing tools, temperature control, metal rolling, etc., can solve problems such as hot-rolled plate edge cracks, billet heating temperature, rolling pass deformation and deformation temperature, etc. Achieve the effect of edge crack elimination, good plasticity and high brittleness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

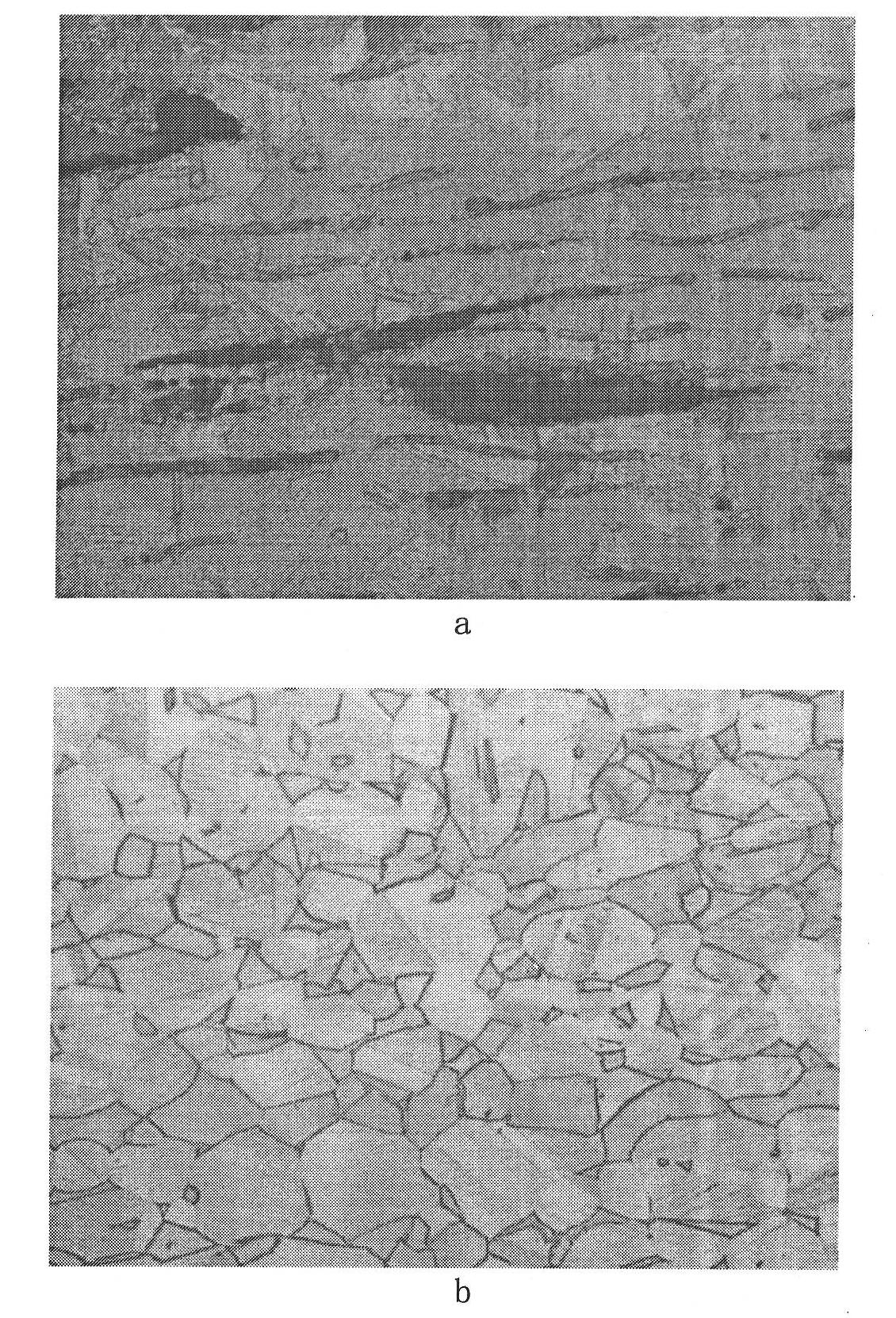

Image

Examples

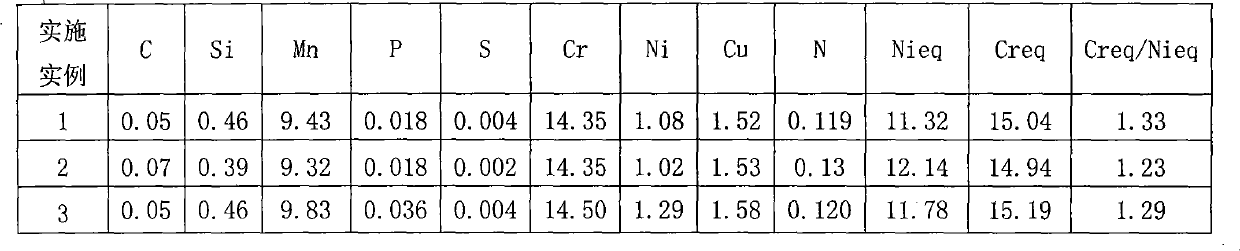

Embodiment 1

[0025] A production process for suppressing edge cracking of a nickel-free austenitic stainless steel hot-rolled plate, the steps are as follows:

[0026] (1) Smelting, continuous casting

[0027] The use of low-cost alloy materials and 100% stainless steel scrap is realized through GOR refining furnace refining. Nitrogen is blown throughout the process, and electrolytic manganese is baked in the furnace for more than 40 minutes. The baking time is reduced or increased depending on the furnace temperature. The blowing time is controlled at 100 minutes. Nitrogen flow inner pipe charging stage 30-35m 3 / min, the first stage 0.5-1.0m 3 / min, furnace tilting stage 25-35m 3 / min, 5-7m in the charging stage of the outer tube 3 / min, furnace tilting stage 5-7m 3 / min, and the use of decarburization and chromium-preserving, gas-phase nitrogen alloying process ensures that the N content in the steel is controlled at 0.119%; the LF furnace is blown with argon throughout the process,...

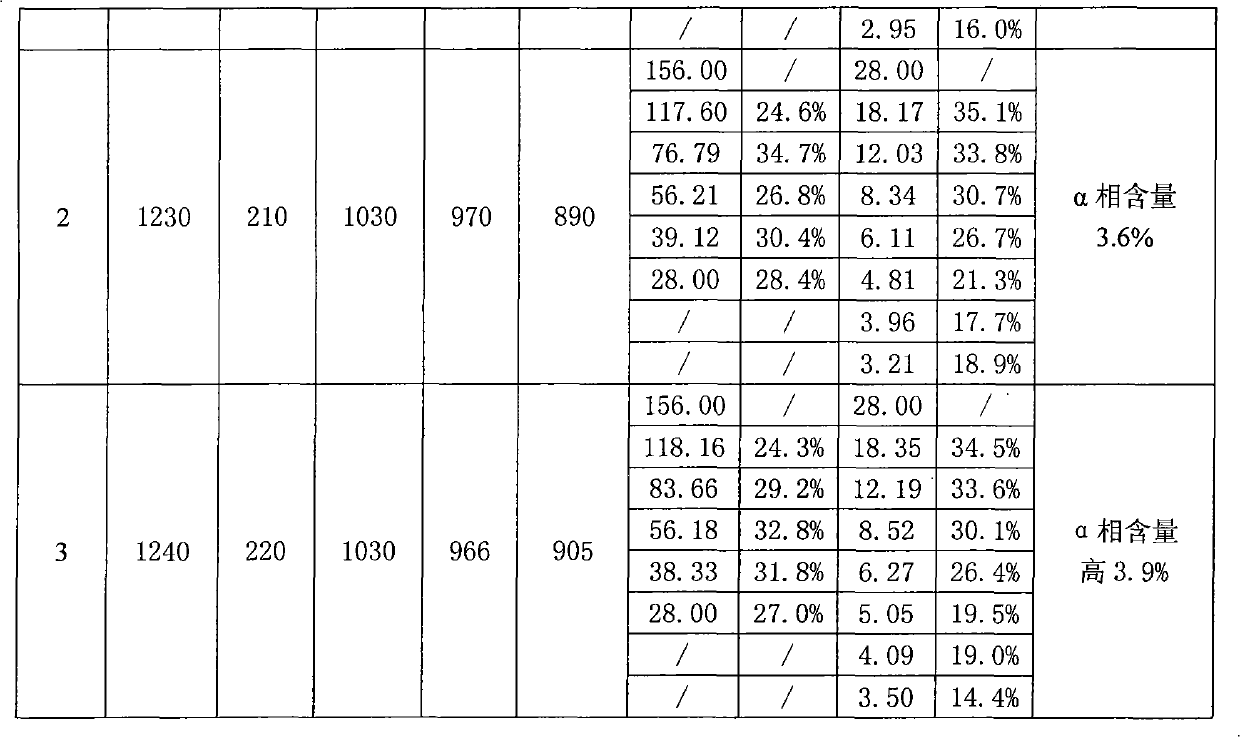

Embodiment 2

[0039] A production process for suppressing edge cracking of a nickel-free austenitic stainless steel hot-rolled plate, the steps are as follows:

[0040] (1) Smelting, continuous casting

[0041] Refining by the GOR refining furnace realizes the use of low-cost alloy material and 100% stainless steel scrap steel, through process control such as furnace alloy baking, blowing time, gas flow (same as the control in embodiment 1), and adopts decarburization and chromium preservation, The gas-phase nitrogen alloying process technology ensures that the N content in the steel is controlled at 0.13%; the LF furnace is blown with argon throughout the process, and the treatment is at least 15 minutes, so as to uniform the composition and temperature, and finally fine-tune the composition. CaSi cored wire (Ф13mm, powder amount ≥ 220g / m) 3-4m / t, soft argon blowing ≥ 5min after tapping, temperature measurement in the first furnace after soft argon blowing is 1540-1550°C, and then 1530-154...

Embodiment 3

[0053] A production process for suppressing edge cracking of a nickel-free austenitic stainless steel hot-rolled plate, the steps are as follows:

[0054] (1) Smelting, continuous casting

[0055] The N content in the steel is controlled at 0.12% (with the control steps in Example 1); the Creq / Nieq is controlled at 1.29; the α-phase content in the slab structure is guaranteed to be controlled at 3.9%;

[0056] (2) Slab grinding

[0057] The continuous casting slab is ground with 48% pressure, the upper and lower sides of the slab are ground once, the side is not ground, and the grinding amount is less than 1mm;

[0058] (3) Blank heating

[0059] The ground blank is heated in the preheating section, heat recovery section, heating section, and soaking section in turn, and then released from the furnace. The temperature of the heat recovery section is ≤800°C, the temperature of the heating section is 1230±20°C, and the temperature of the soaking section is 1230±20°C. , furnac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com