Active energy ray-curable coating composition, method for formation of coating film, and coated article

An active energy ray, curing coating technology, applied in the device, coating, surface pretreatment of surface coating liquid, etc., can solve the problems of increased solvent usage, low degree of freedom, insufficient photocurability, etc. Low emissions, reduced usage, and excellent alkali resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0226] Hereinafter, the present invention will be described more concretely by way of examples, but the present invention is not limited thereto. In addition, "part" and "%" mean "parts by mass" and "% by mass" unless otherwise indicated.

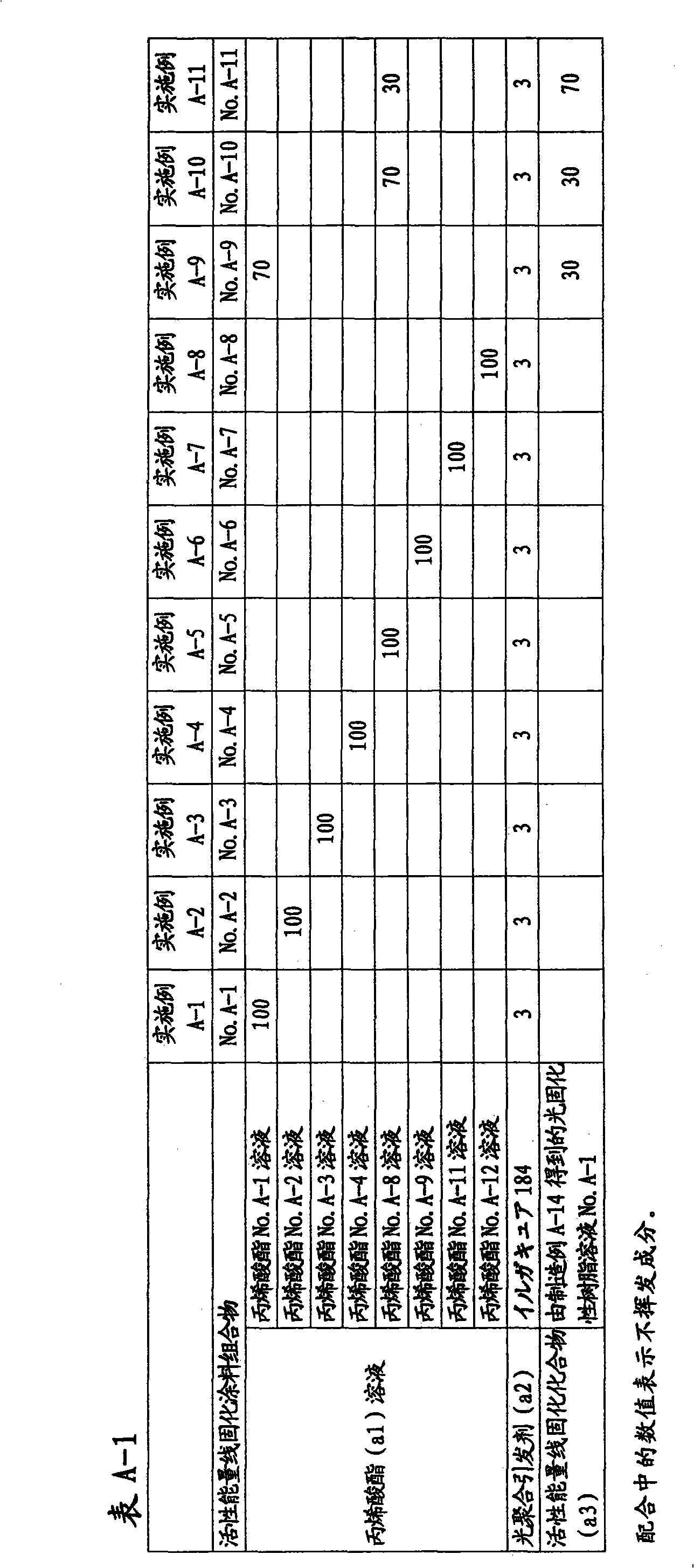

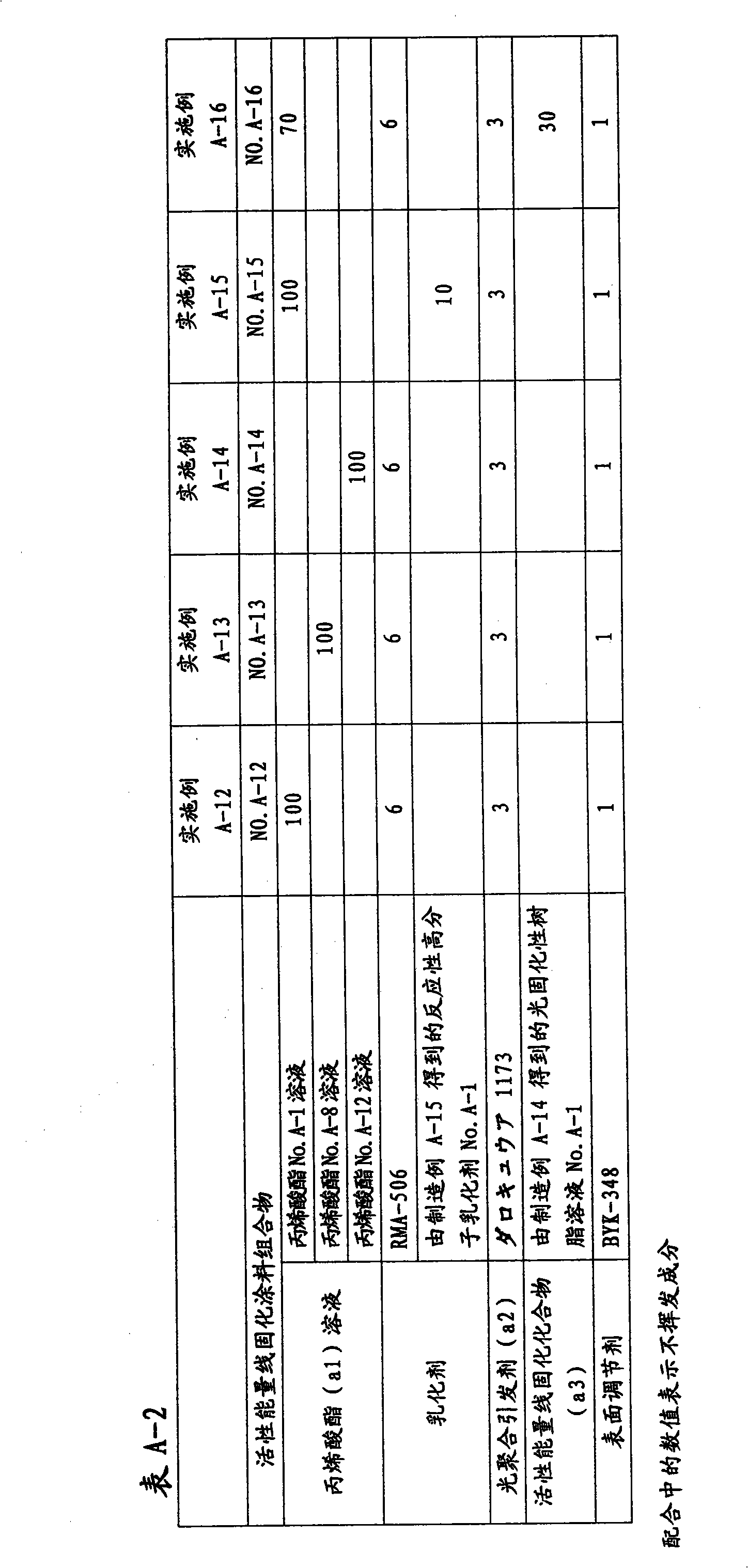

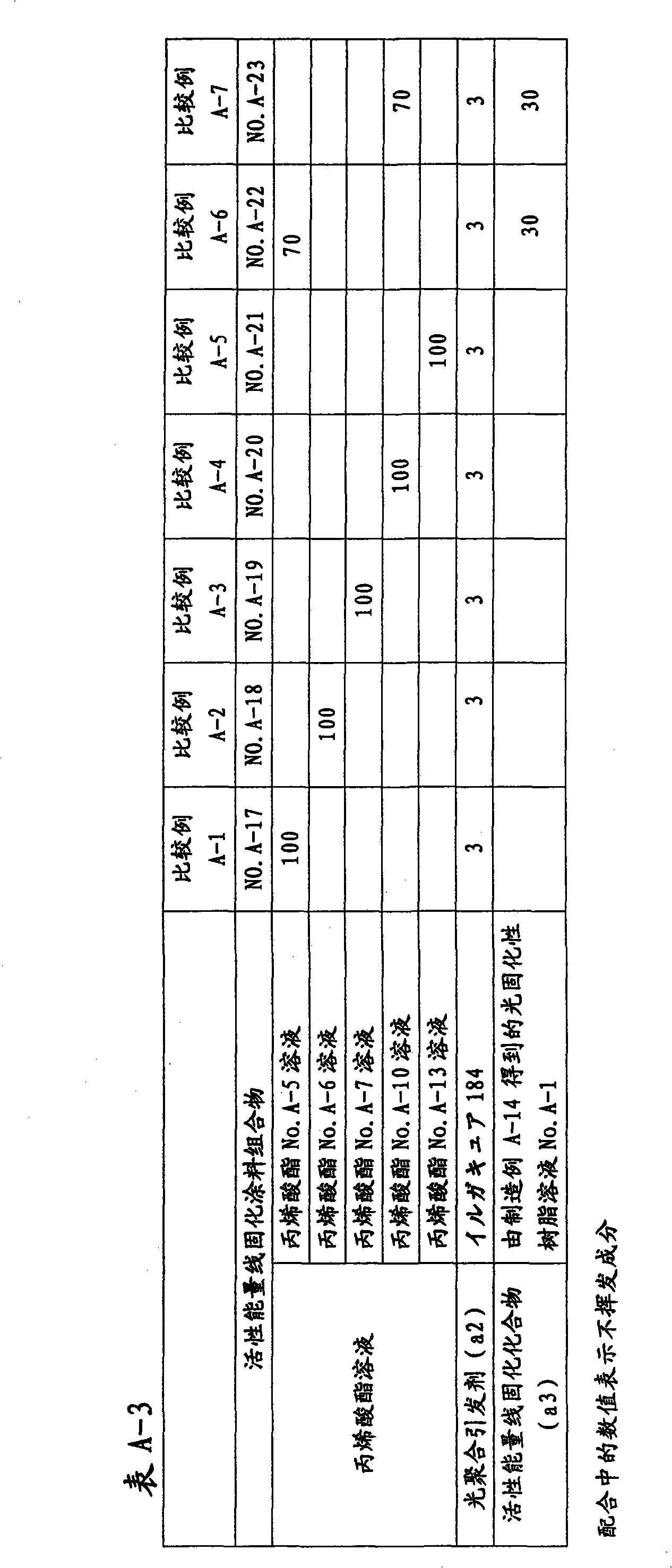

[0227] "A. Examples related to active energy ray-curable coating compositions"

manufacture example A-1

[0229] Production example of acrylate No.A-1 solution (for example)

[0230] Add 80 parts of dextrin (I) (glucose polymer with an average polymerization number of 4, with an average of 14 hydroxyl groups per molecule), 100 parts of methyl isobutyl ketone, methyl 0.16 parts of hydroquinone, 5.9 parts of lithium hydroxide monohydrate and 506.2 parts of methyl acrylate.

[0231] Next, nitrogen gas was blown into this solution, and it heated to 90 degreeC, stirring, and methyl acrylate, methanol, and methyl isobutyl ketone were distilled off to the outside of the system little by little. With respect to the methyl acrylate and methyl isobutyl ketone which decreased by distillative removal, the decreased amount was added to the reaction container.

[0232] Next, the methanol in the reaction container and the methanol distilled off were quantitatively followed by the measurement of gas chromatography, and the reaction was followed, and the dextrin (I) was cooled when an average of...

manufacture example A-2

[0234] Production example of acrylate No.A-2 solution (for example)

[0235] In Production Example A-1, the methanol in the reaction container and the methanol distilled off were quantitatively measured by gas chromatography to follow the reaction and prolong the reaction time until the dextrin (I) had an average of 14 hydroxyl groups per molecule. Except for the fact that 10.0 hydroxyl groups on average were acrylated, in the same manner as Production Example A-1, Acrylate No. A-2 of the present invention having a weight average molecular weight of 1,400 and an average of 10.0 acryloyl groups per molecule was obtained. solution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com