Dual fluid nozzle atomizing and cooling closed system for high-power solid laser

A dual-fluid nozzle and solid-state laser technology, which is applied to lasers, laser components, phonon exciters, etc., can solve problems such as the inability to meet the low temperature requirements of the heat exchange surface, complex system structure, etc., and achieve the goal of avoiding dead zones and low exchange rate Hot surface temperature demand, effect of increasing heat transfer capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

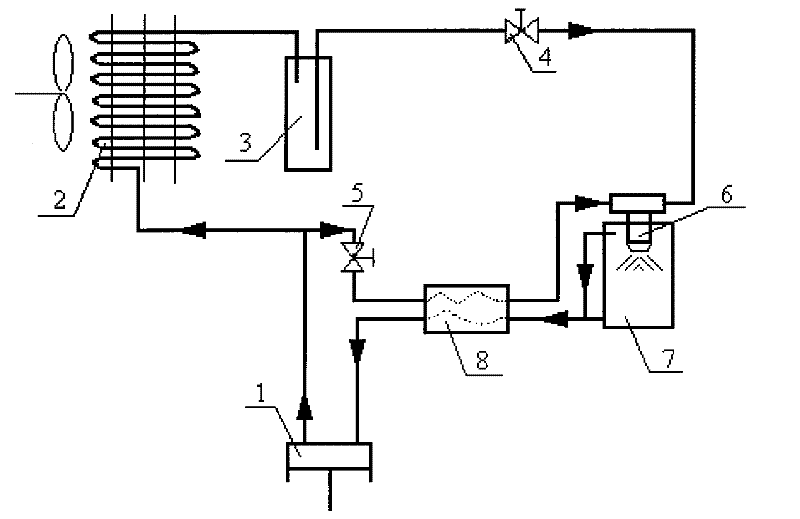

[0026] figure 2 The structural representation of an embodiment of the present invention that provides, its structure is:

[0027] An opening on the discharge pipe of the compressor 1 is connected to the gas phase inlet of the heat exchanger 8 via the second control valve 5; the gas phase outlet of the heat exchanger 8 is connected to the gas chamber of the two-fluid nozzle 6; The exhaust pipe of the compressor 1 is connected to the input end of the condenser 2; the output end of the condenser 2 is connected to the input end of the liquid receiver 3; the output end of the liquid receiver 3 is connected to the dual The liquid chamber of the fluid nozzle 6 is connected; the spray head of the two-fluid nozzle 6 extends into the heat sink 7; The inlet is connected; the superheated steam outlet of the heat exchanger 8 is connected with the suction pipe of the compressor 1 .

[0028] Its workflow is as follows:

[0029] Part of the high-pressure gas is introduced from an opening ...

Embodiment 2

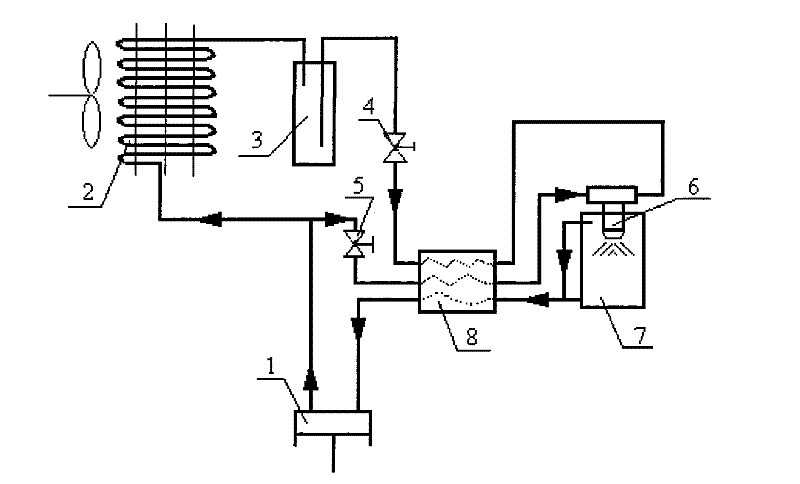

[0031] In order to further ensure the suction dryness of compressor 1 and further reduce the temperature of the liquid source, image 3 The structure of another embodiment of the present invention is as follows: on the basis of embodiment 1, the following structure is added: that is, the output end of the liquid reservoir 3 communicates with the heat through the first control valve 4 The liquid phase inlet of the heat exchanger 8 is connected, and the liquid phase outlet of the heat exchanger 8 is connected with the liquid chamber of the two-fluid nozzle 6 .

[0032] Its workflow is as follows:

[0033] Part of the high-pressure gas is introduced from an opening on the exhaust pipe of the compressor 1 as the gas source, passes through the second control valve 5 and the heat exchanger 8, and then enters the air chamber of the dual-fluid nozzle 6, and the rest of the high-pressure gas flows into the air chamber after being condensed by the condenser 2 The liquid receiver 3, the...

Embodiment 3

[0035] In order to ensure the full utilization of compressor suction dryness and liquid source, Figure 4 Another embodiment of the present invention is given, its structure is: on the basis of Embodiment 1, the following structure is added: that is, the top opening of the heat sink 7 is connected to the heat exchanger 8 through the refrigerant pipeline. The gas phase inlet is connected; the superheated steam outlet of the heat exchanger 8 is connected with the suction pipe of the compressor 1; the bottom opening of the heat sink 7 is connected with the inlet of the liquid pump 10 through the third control valve 9; the outlet of the liquid pump 10 It is connected with the liquid return port of the reservoir 3.

[0036] Its workflow is as follows:

[0037] Part of the high-pressure gas is drawn up from the exhaust pipe of the compressor 1 as a gas source and enters the air chamber of the double-fluid nozzle 6 after passing through the second control valve 5 and the heat exchan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com