Compound method for preparing magnesium alloy having superhydrophobic surface

A super-hydrophobic surface, magnesium alloy technology, applied in the field of super-hydrophobic surface preparation of magnesium alloys, can solve the problems of poor controllability and time-consuming, and achieve the effects of easy operation, convenient operation, and simple and easy preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

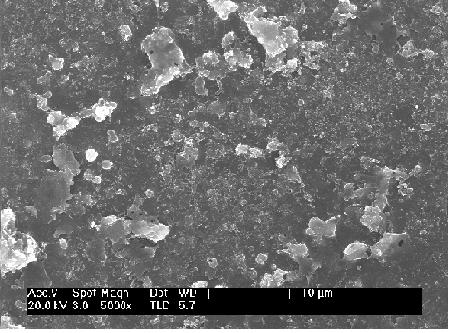

[0029] The surface of AZ31 magnesium alloy was chemically etched with sulfuric acid aqueous solution with a concentration of 7g / L, the etching temperature was 20°C, and the etching time was 10min, so as to build a first-level rough structure on the surface【 figure 1 Shown]. Clean the magnesium alloy after sulfuric acid etching with deionized water to remove residual sulfuric acid, then take it out and dry it for later use;

[0030] Prepare the myristic acid electrolyte: dissolve myristic acid and glycerin in ethanol, the concentration of myristic acid is 3wt%, the concentration of glycerin is 0.9wt%, and the concentration of ethanol is 96.1wt%.

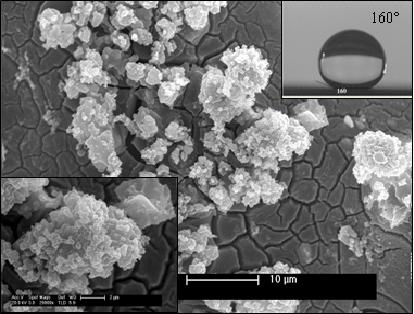

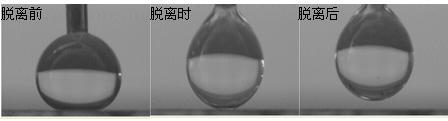

[0031] The nickel is used as the cathode, and the above chemically etched magnesium alloy is used as the anode, placed in the myristic acid electrolyte, the electrolysis temperature is 20°C, the voltage is 3V, and the electrolysis time is 1 hour. After the anodic oxidation treatment, take out the magnesium alloy, wash it with deioni...

Embodiment 2

[0035] The surface of the AZ31 magnesium alloy was chemically etched with sulfuric acid aqueous solution with a concentration of 15g / L, the etching temperature was 20°C, and the etching time was 5min, so as to build a first-level rough structure on the surface. Clean the magnesium alloy after sulfuric acid etching with deionized water to remove residual sulfuric acid, then take it out and dry it;

[0036] Prepare the myristic acid electrolyte: dissolve myristic acid and glycerin in ethanol, the concentration of myristic acid is 6wt%, the concentration of glycerol is 1.4wt%, and the concentration of ethanol is 92.6wt%.

[0037] The nickel is used as the cathode, and the above chemically etched magnesium alloy is used as the anode, placed in the myristic acid electrolyte, the electrolysis temperature is 20°C, the voltage is 7V, and the electrolysis time is 0.5 hours. After the anodic oxidation treatment, the magnesium alloy was taken out, washed with deionized water, placed in a...

Embodiment 3

[0041] A composite preparation method of a magnesium alloy with a superhydrophobic surface, said method comprising the following steps:

[0042](1) The surface of the magnesium alloy is chemically etched using an aqueous solution of sulfuric acid with a mass volume concentration of 5g / L~20g / L. The etching temperature is 20°C~30°C, and the etching time is 5min~10min. In this embodiment Among them, the mass volume concentration of sulfuric acid aqueous solution is 5g / L or 20g / L, the etching temperature is 20°C or 30°C, and the etching time is 5min or 10min,

[0043] (2) Using myristic acid solution as the electrolyte, using the anodic oxidation method, the structure of the secondary structure and the modification of the low surface energy are simultaneously carried out on the surface of the magnesium alloy. The described myristic acid solution is to dissolve myristic acid and glycerin in ethanol , the concentration of myristic acid is 2wt%~6wt%, the concentration of glycerin is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com