Method for gas nitriding sampling detection without shutting down furnace and nitriding furnace used thereby

A detection method and gas nitriding technology, applied in metal material coating process, coating, solid-state diffusion coating, etc., can solve the problems of inability to sample, long nitriding time, and high cost, so as to reduce nitriding time and improve Qualification rate, cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

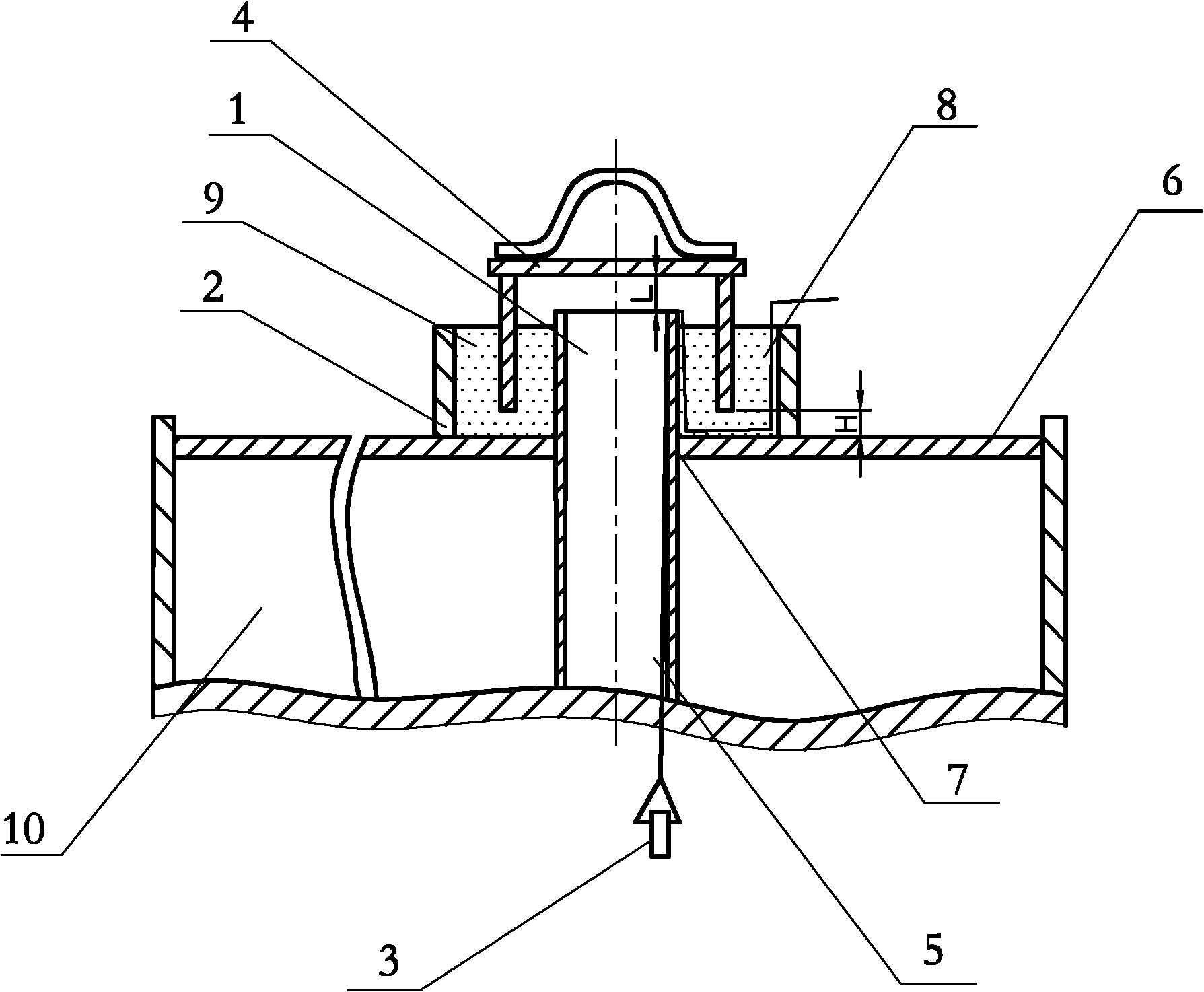

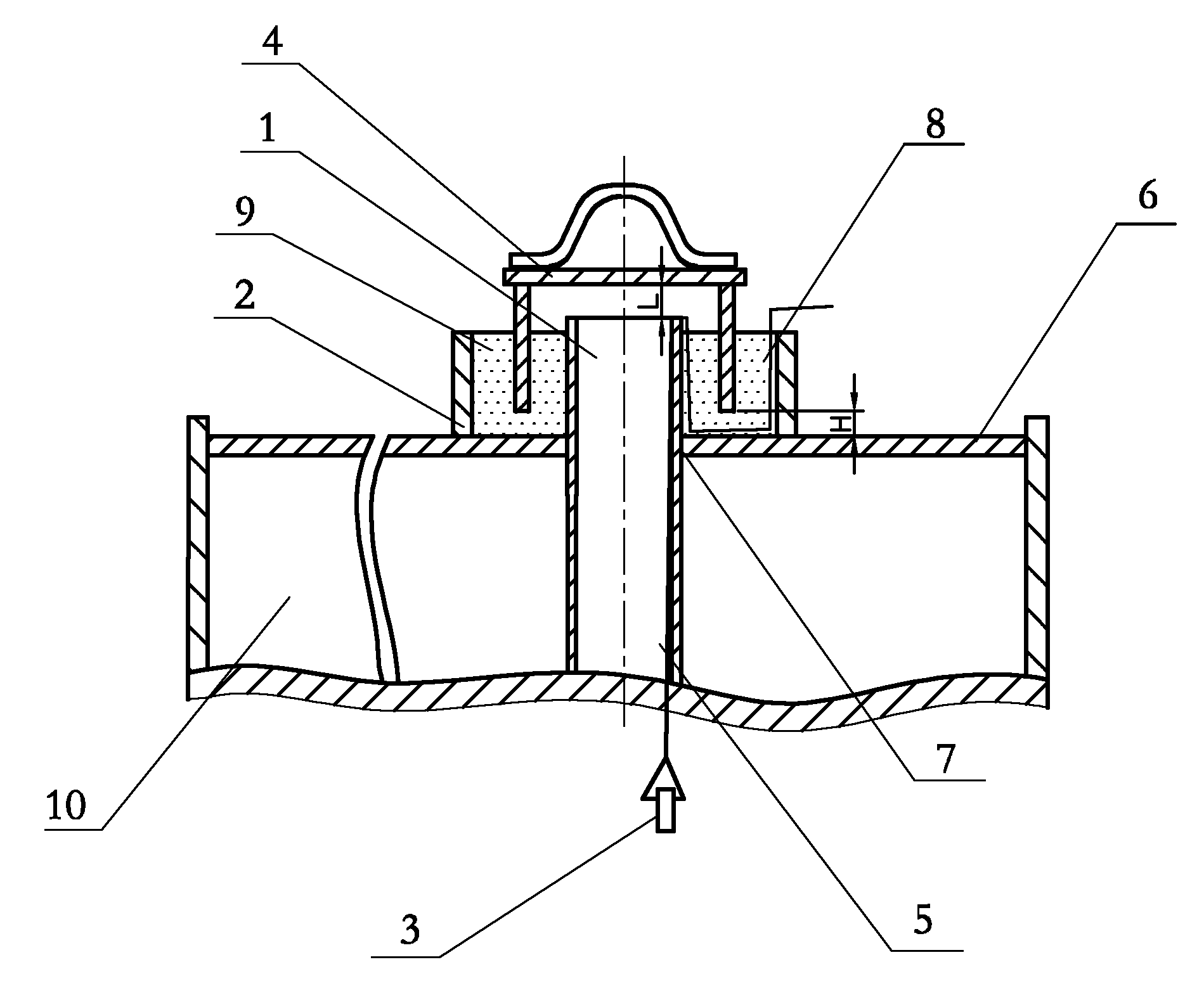

[0017] Specific implementation mode one: combine figure 1 Describe this embodiment, the specific steps of the non-stop gas nitriding sampling detection method of this embodiment are as follows:

[0018] Step 1: Perform anti-nitridation treatment on the non-nitrided surface of the workpiece;

[0019] Step 2: Open the nitriding furnace, put the workpiece and the final inspection sample accompanying the workpiece into the nitriding tank 10;

[0020] Step 3: each nitriding sample 3 is suspended in the nitriding tank 10 by a sampling wire 5;

[0021] Step 4: Cover the sealing cover 4 of the sampling hole, start the nitriding furnace, feed ammonia gas, and heat the nitriding tank 10 to 450°C-650°C;

[0022] Step 5: Carry out nitriding heat preservation according to the process parameters;

[0023] Step 6: When the holding time is close to the process specification, open the sealing cover 4 of the sampling hole, pull a sampling wire 5 to take out the corresponding nitrided sample ...

specific Embodiment approach 2

[0025] Specific implementation mode two: combination figure 1 To illustrate this embodiment, in step 3, the nitriding sample 3 is hung in the nitriding tank 10 near the workpiece. In this embodiment, the nitriding sample and the workpiece are nitrided synchronously, and the detection result is the most ideal. Other methods are the same as in the first embodiment.

specific Embodiment approach 3

[0026] Specific implementation mode three: combination figure 1 Describe this embodiment, the nitriding furnace used in this embodiment in order to realize the gas nitriding non-stop sampling detection method described in the first specific embodiment, the nitriding furnace includes a nitriding tank 10 and a nitriding tank upper cover 6, nitrogen The nitriding tank upper cover 6 is sealed and installed on the nitriding tank 10, and the nitriding furnace also includes a sampling hole 1, a sand-sealed outer ring 2, a sealing cover for the sampling hole 4, a plurality of nitriding samples 3, and a connection with the nitriding sample 3. The same number of sampling wires 5, a sampling port 7 is opened on the upper end surface of the upper cover 6 of the nitriding tank, the sampling hole 1 is sealed and inserted in the sampling port 7, and the upper end surface of the sampling hole 1 is higher than the upper cover 6 of the nitriding tank The lower end of the sampling hole 1 is plac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com