Nanometer clay-containing high absorptive hydrogel as well as preparation method and application thereof

A nanoclay, high adsorption technology, applied in the direction of adsorption water/sewage treatment, chemical instruments and methods, other chemical processes, etc., to achieve high practical value, simple preparation method, strong adsorption and removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

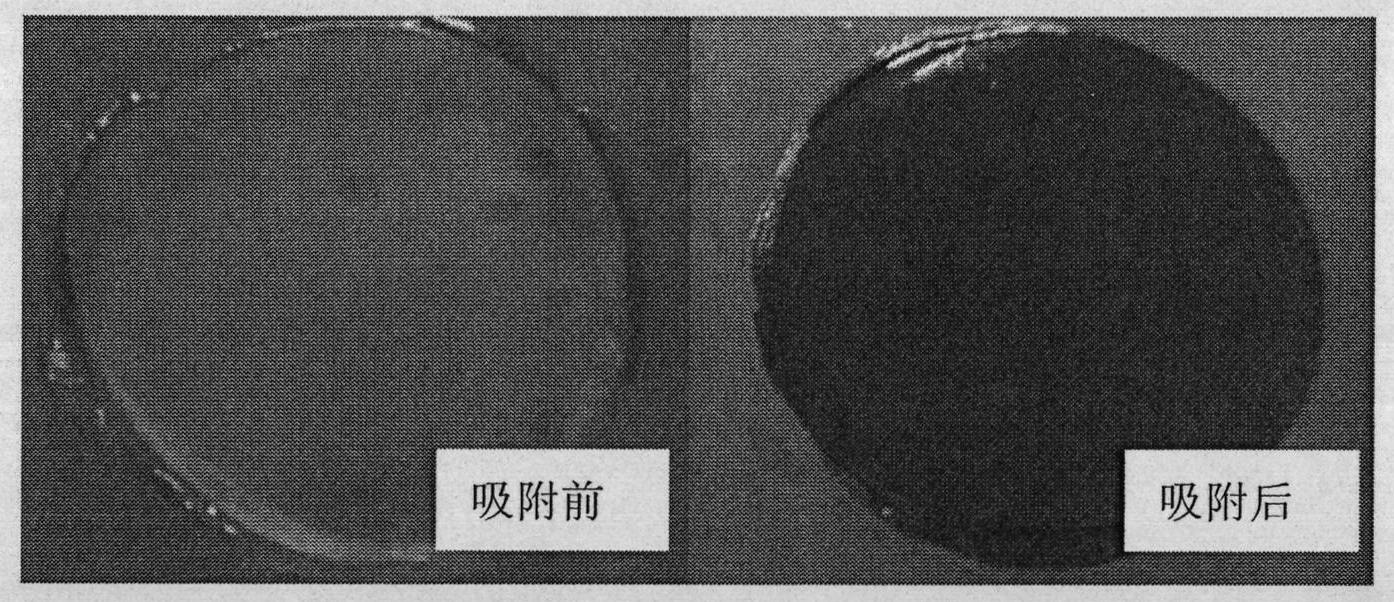

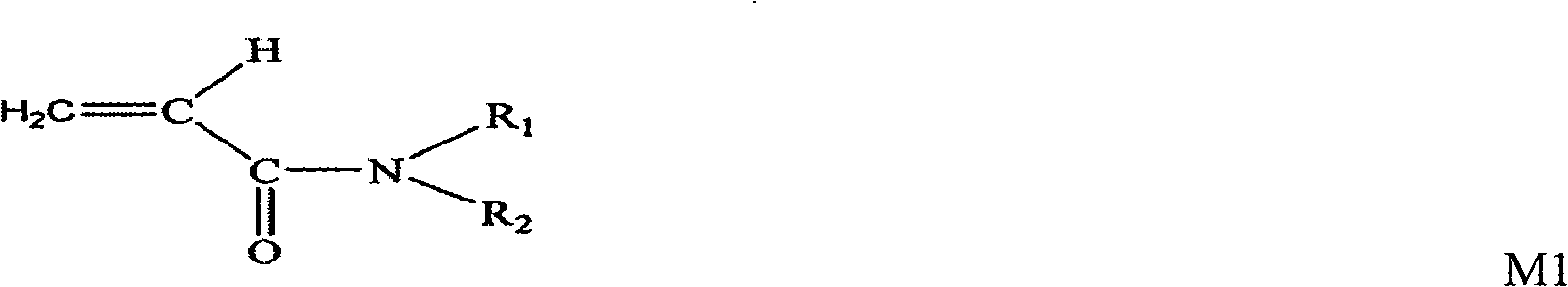

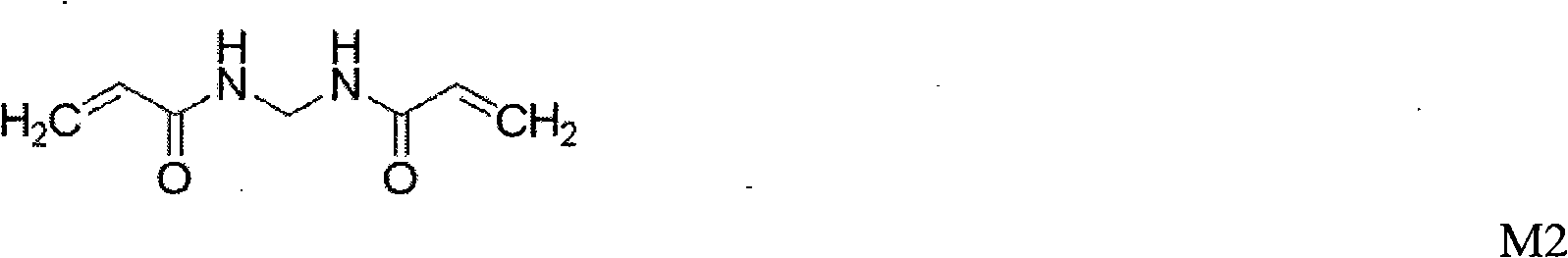

[0047] Add 1.0g of isopropylacrylamide, 0.01g of methylenebisacrylamide, 0.09g of laponite, and 0.05g of starch into 11mL of deionized water in sequence, and in a sealed container at 20°C, blow nitrogen into it, and stir for 50min until Completely disperse to form a homogeneous solution; cool the above mixed solution to 3°C with ice cubes, add 0.01 g of ammonium persulfate after 30 minutes, and inject 100 μL of N, N, N'N'-tetramethylethylenediamine after 10 minutes, under nitrogen protection, Continue to stir for 10 minutes until the mixed solution starts to appear viscous; immediately pour the viscous mixed solution into a glass mold with a thickness of 2mm, leave it at 25°C for a sealed reaction for 24 hours, and then soak the reaction product in deionized water After 2 weeks, the purified hydrogel was obtained; the purified hydrogel was dried for 25 hours in a blast drying box at 30°C, and then placed in a water-soluble cationic dye crystal violet solution with a mass concen...

Embodiment 2

[0049] Add 1.0g of acrylamide, 0.05g of methylenebisacrylamide, and 0.05g of sauconite to 10mL of deionized water in sequence, and in a sealed container at 20°C, blow nitrogen into it, and stir for 40min until completely dispersed to form a uniform solution; Cool the above mixed solution to 1°C with ice cubes, add 0.01g of potassium persulfate after 30 minutes, inject 50 μL of sodium bisulfite after 10 minutes, and continue to stir for 10 minutes under the protection of nitrogen until the mixed solution begins to appear viscous; Immediately pour the mixed solution into a glass mold with a thickness of 2 mm, leave it at 20°C for a sealed reaction for 30 hours, and then soak the reaction product in deionized water for 2 weeks to obtain a purified hydrogel; the purified hydrogel The gel was dried for 30 hours in a blower drying box at 25°C, and then placed in a water-soluble anionic dye methyl orange solution with a mass concentration of 10%. After 10 hours, the high-adsorption hy...

Embodiment 3

[0051] Add 1.0g of diethylacrylamide, 0.10g of lithium magnesium silicate, and 0.05g of sodium alginate to 11mL of deionized water in sequence, and in a sealed container at 20°C, pass in nitrogen gas and stir for 45min until completely dispersed to form a homogeneous solution; Cool the above mixed solution to 2°C with ice cubes, add 0.02 g of potassium persulfate after 30 min, inject 80 μL of N, N, N'N'-tetramethylethylenediamine after 10 min, and continue to stir for 10 min under nitrogen protection until mixed The solution began to appear viscous; the viscous mixed solution was immediately poured into a glass mold with a thickness of 2mm, left to stand at 28°C for a sealed reaction for 16 hours, and then the reaction product was soaked in deionized water for 2 weeks to obtain purified The hydrogel; the purified hydrogel is placed in a blast drying air box at 20°C for 35 hours, and then placed in a water-soluble cationic dye toluidine blue solution with a mass concentration of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com