Packaging adhesive film composition and application thereof

A technology for encapsulating adhesive films and compositions, which is applied in the fields of renewable energy integration, sustainable architecture, climate sustainability, etc. It can solve the problems of long molding cycle, high price, and inappropriateness, and achieve excellent aging resistance, anti-aging High die weight and good bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

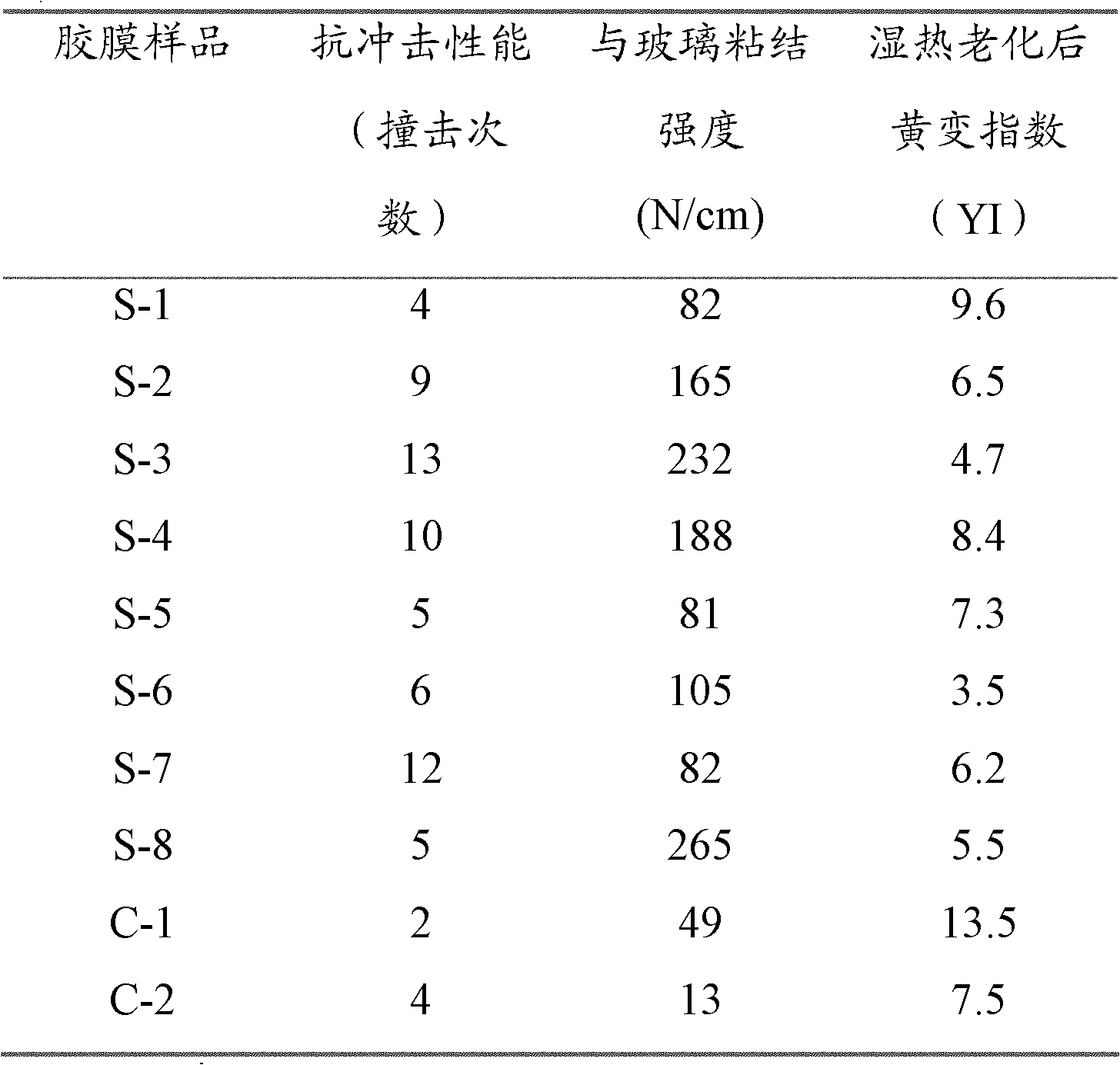

Examples

Embodiment 1

[0026] In terms of mass fraction, 95 parts of VA (vinyl acetate) mass content is 33% ethylene-vinyl acetate copolymer (U.S. DuPont PV 1200), adding 2 parts of Mooney viscosity is 31 ethylene-octene copolymer ( U.S. Exxon Mobil Corporation POE 5061), add 2 parts of medium molecular weight polyisobutylene (German BASF B15SFN), 0.05 part of UV absorber 2-(2-hydroxyl-3,5-di-tert-amylphenyl) benzotriazole (U.S. Ciba Specialty Chemicals UV-328), 0.05 part of histamine antioxidant Reagent poly[[6-1,1,3,3,-tetra-methylbutyl)amino]-S-triazine-2,4-diyl], [[(2,2,6,6-tetra Methyl-4-piperidinyl) imino]] CHIMASSORB 944 (U.S. Ciba Specialty Chemicals), 1.5 parts of peroxide cross-linking agent tert-butylperoxyneodecanoic acid ( TAPD), and mix well.

[0027] The mixture is blended and extruded in an extruder, and the temperature is controlled at 90°C. The extruded product is cast, cooled, cut, and coiled to obtain a packaging film with a thickness of 0.5mm, which is denoted as S- 1.

Embodiment 2

[0029] In terms of mass fraction, 65 parts of VA content is 15% ethylene-vinyl acetate copolymer (Elvax 250 of Mitsui DuPont Co., Ltd. of Japan), and 20 parts of Mooney viscosity is 5.0 ethylene-octene copolymer (U.S. Exxon Mobil Corporation POE 0210), add 9.5 parts of medium molecular weight polyisobutylene (German BASF B12N), add 2 parts of UV absorber 2-(2'-hydroxyl-5-methylphenyl) benzotriazole, 0.5 parts of antioxidant bis-2,2,6,6-tetramethyl Piperidinol ester (Tinuvin 770), 3 parts crosslinker o, o-tert-amyl-o-(2-ethylhexyl)-mono-peroxycarbonate (AkzoNobel Peroxide Ltd.), and well mixed.

[0030] The mixture is blended and extruded in an extruder, and the temperature is controlled at 90°C. The extruded product is cast, cooled, cut, and coiled to obtain a packaging film with a thickness of 0.5mm, which is denoted as S- 2.

Embodiment 3

[0032] In terms of mass fraction, in 68 parts of ethylene-vinyl acetate copolymer (Japan Ube V215) with VA content of 15%, add 17 parts of ethylene-octene copolymer with Mooney viscosity of 18.0 (POE 5101), add 12 parts of medium molecular weight polyisobutylene (Zhejiang Shunda Polymer Material Co., Ltd.), 0.05 part of UV absorber 2-(2'-hydroxyl-5-methylphenyl) benzotriazole, 2 parts of antioxidant Agent 1,3,5-tris(4-tert-butyl-3-hydroxy-2,6-dimethylbenzyl)-1,3,5-triazine-2,4,6-(1H,3H ,5H)-triketone / bis(2,4-dicumylphenyl)pentaerythritol diphosphite complex CYANOX 2777, 1 part crosslinker o,o-tert-butyl-o-(2-ethyl Hexyl)-mono-peroxycarbonate ( TBEC), and mix well.

[0033] The mixture is blended and extruded in an extruder, and the temperature is controlled at 90°C. The extruded product is cast, cooled, cut, and coiled to obtain a packaging film with a thickness of 0.5mm, which is denoted as S- 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com