Automobile driven by thermoacoustic engine

A thermoacoustic engine and automobile technology, which is applied to machines/engines, mechanisms that generate mechanical power, mechanical equipment, etc., can solve the problems of limited thermal energy, low power, and no thermoacoustic engine gas compression system without moving parts. , to achieve the effect of reducing fuel consumption and reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

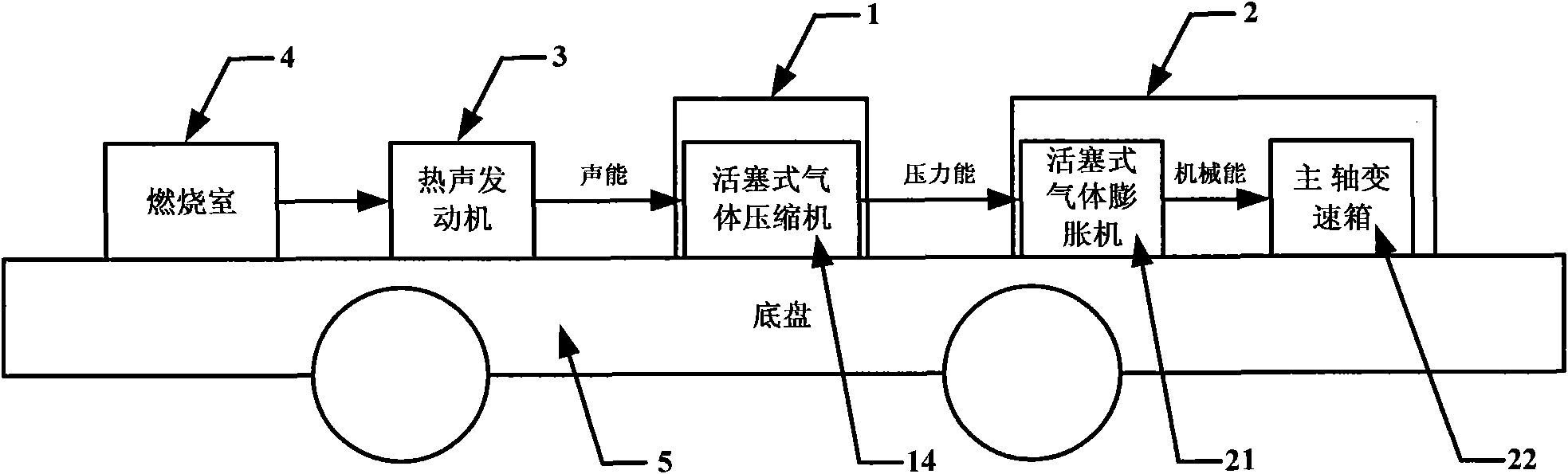

[0054] Such as figure 1 Shown is a schematic diagram of a car driven by a thermoacoustic engine whose acoustic energy conversion system is a diaphragm gas compressor. The car driven by a thermoacoustic engine includes a thermoacoustic engine and a chassis, wherein the thermoacoustic engine is placed on the chassis. The car powered by the thermoacoustic engine also includes a combustion chamber, a piston gas compressor, a gas expander, and a spindle gearbox, the combustion chamber, the piston gas compressor, the piston gas expander, the spindle transmission The tanks are placed on the chassis, and the combustion chamber is connected to the input end of the thermoacoustic engine, the output end of the thermoacoustic engine is connected to the input end of the piston gas compressor, and the piston gas compressor The output end of the compressor is connected to the input end of the piston gas expander, the output end of the piston gas expander is connected to the input end of the ...

Embodiment 2

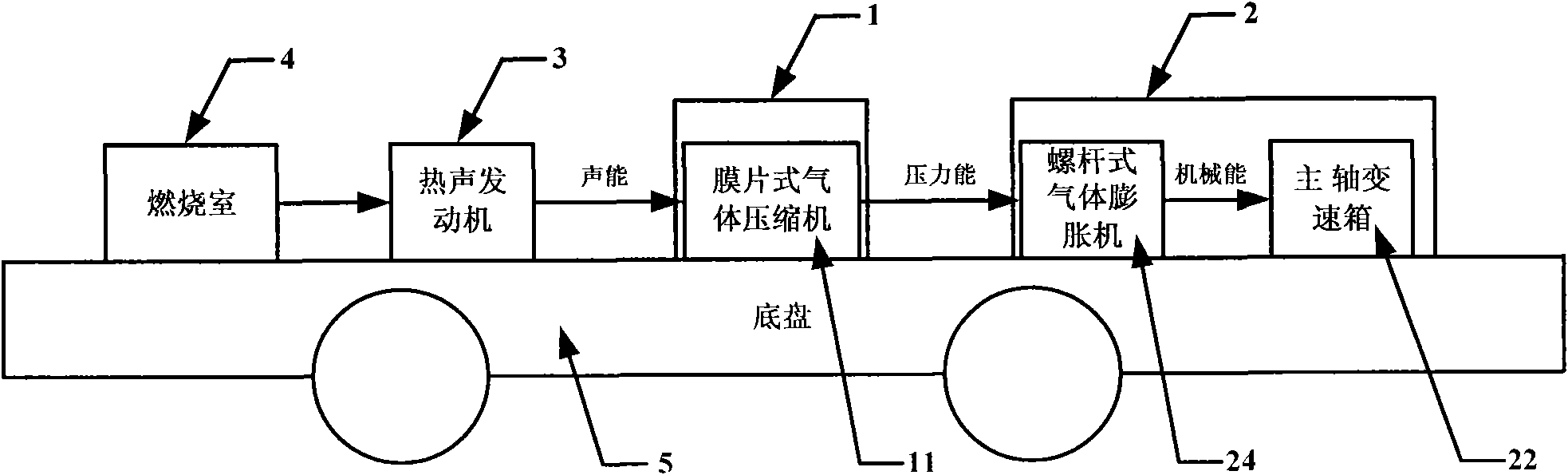

[0057] The piston gas compressor in Embodiment 1 is replaced by a diaphragm gas compressor, and the piston gas expander is replaced by a screw gas expander, such as figure 2 Shown, others are with embodiment 1.

Embodiment 3

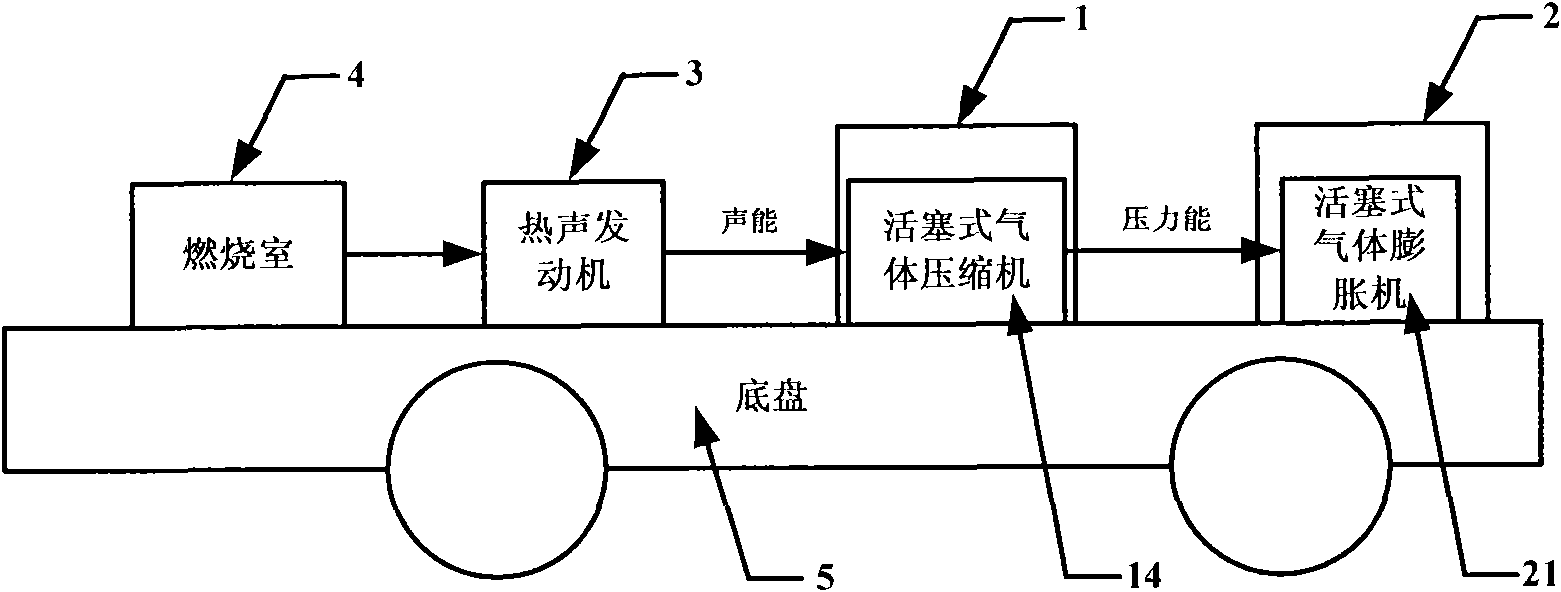

[0059] Such as image 3 Shown is a schematic diagram of a car driven by a thermoacoustic engine whose acoustic energy conversion system is a piston gas compressor. The car driven by a thermoacoustic engine includes a thermoacoustic engine and a chassis, wherein the thermoacoustic engine is placed on the chassis, and the thermoacoustic engine The vehicle powered by the acoustic engine also includes a combustion chamber, a piston gas compressor, and a piston gas expander, the combustion chamber, the piston gas compressor, and the piston gas expander being placed on the chassis, and The combustion chamber is connected to the input end of the thermoacoustic engine, the output end of the thermoacoustic engine is connected to the input end of the piston gas compressor, and the output end of the piston gas compressor is connected to the The input end of the piston type gas expander is connected, and the output end of the piston type gas expander drives the wheels of the automobile to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com