New process for realizing inline positioning and cold stamping of intaglio printing and transferring of positioned C2

A gravure printing and new process technology, applied in the direction of printing, printing devices, etc., can solve the problems of many product processes, low production efficiency, high product consumption, etc., and achieve the effect of reducing production processes, high production efficiency and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0041] Realize gravure printing on-line positioning cold ironing and positioning C 2 The new process of transfer can be realized by the following steps:

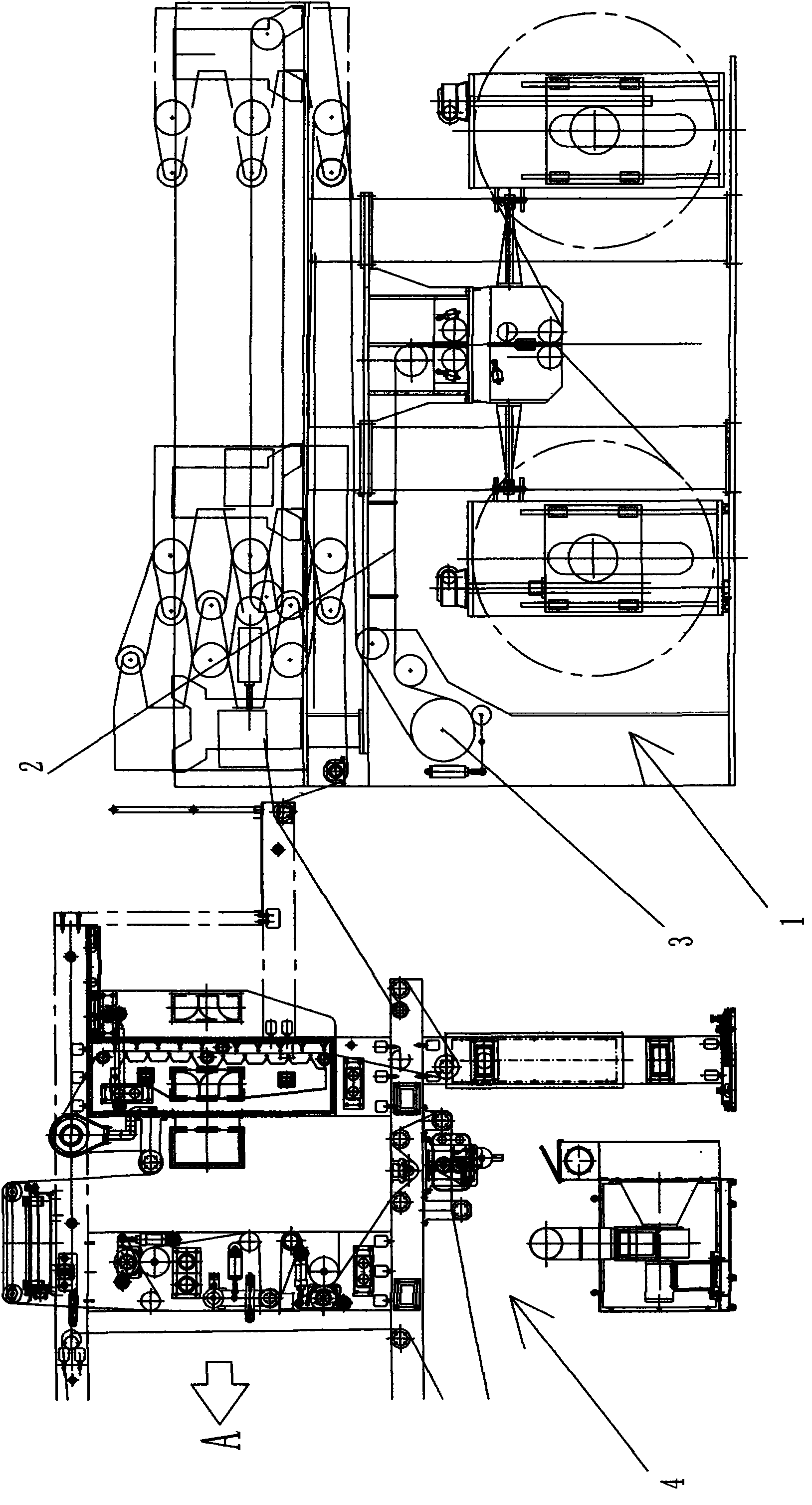

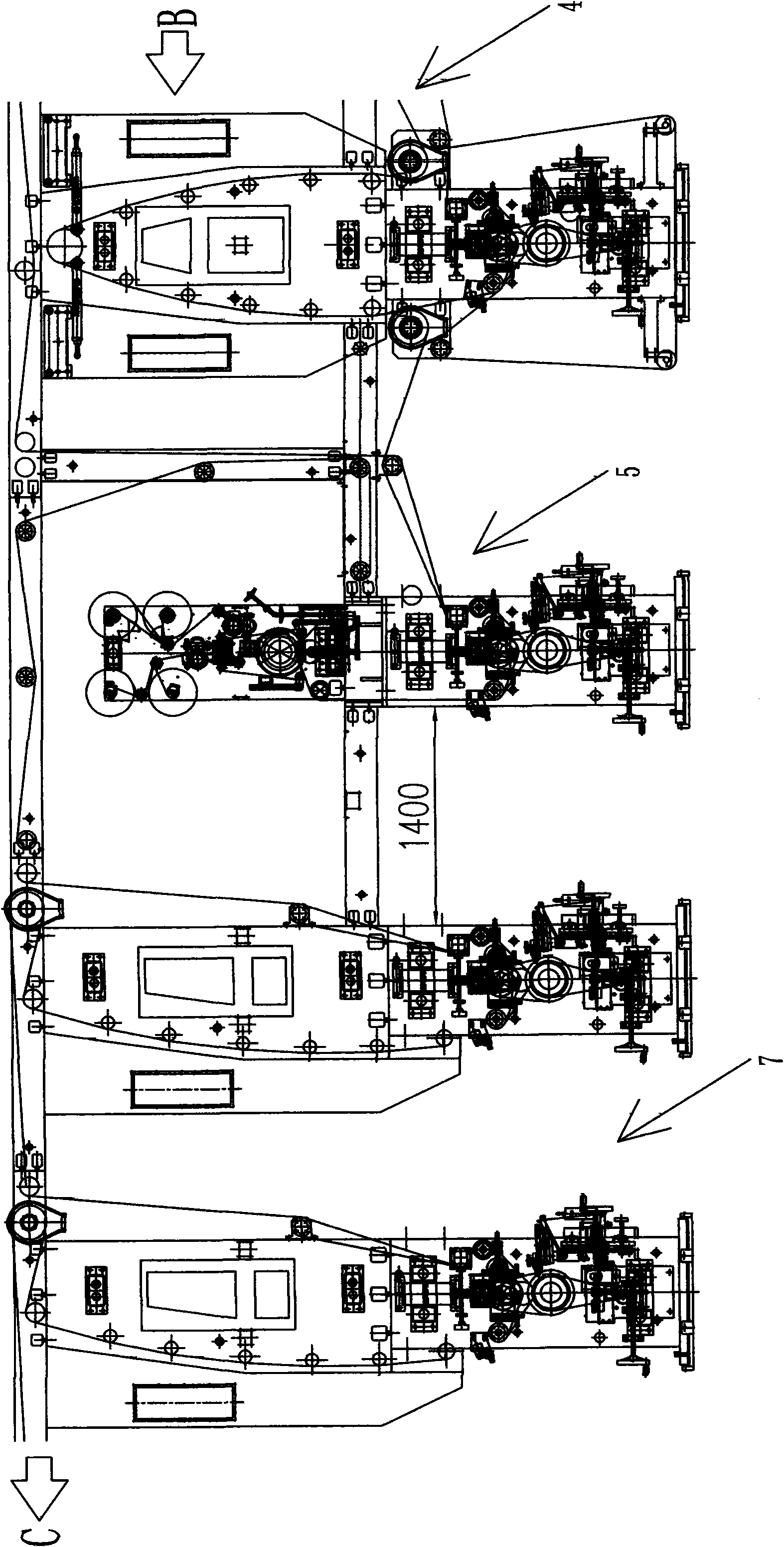

[0042] a. First put the roll paper into the unwinding device 1 of the printing press.

[0043] b. Secondly, the roll paper 2 is pulled out and pulled to the discharge pulling roller 3 .

[0044] c. The paper 2 coming out of the discharge traction roller 3 enters the first printing color group 4 for pattern printing.

[0045] d. After being printed by the first printing color group 4 , the paper 2 enters the cold stamping unit 5 . The transfer layer placed on the transfer film 6 inside the cold pressing unit 5 is positioned and transferred on the paper 2 .

[0046] e. After positioning and transfer by the cold pressing unit 5, it enters the multi-color printing color group 7 to print patter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com