Spherical hammer head of combined crusher and manufacturing method thereof

A combined and crusher technology, applied in the direction of manufacturing tools, casting molding equipment, casting mold components, etc., can solve the problems of large difference in chemical composition mass fraction, waste of hammer handle metal materials, inconvenient recycling and remelting, etc., and achieve savings. Hammer handle material, the effect of reducing labor intensity and reliable connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

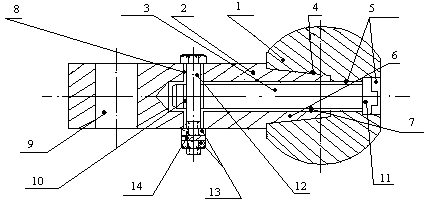

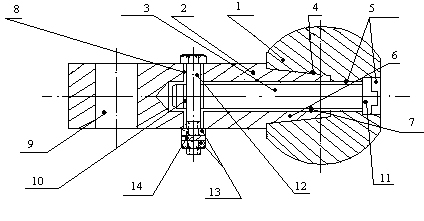

[0021] Example 1: The spherical hammer head of a combined crusher with a ball diameter of 160 mm is produced. The spherical hammer end of the hammer head is made of alloyed high-chromium cast iron by lost foam casting. The mass fraction of the chemical composition of the alloyed high-chromium cast iron is: C 3.02 %, Si 0.51%, S 0.03%, P 0.04%, Mn 0.91%, Cu 0.45%, Cr 19.25%, MO 0.42%, V 0.14%, W 0.51%, RE 0.081%, B 0.072%, Fe 74.567%; Among them, the hammer handle of the hammer head is made of a finished round steel material with a steel number of 45 and a diameter of 80 mm by gold machining and cutting.

[0022] The manufacturing method of the hammer head of the present invention is as follows: the manufacturing method includes the manufacturing process of the hammer handle and the production process of the spherical hammer end alloy high-chromium cast iron, the lost foam casting process, the heat treatment process and the assembly process of the spherical hammer end and the ha...

Embodiment 2

[0028] Example 2: The spherical hammer head of a combined crusher with a ball diameter of 180 mm is produced. The spherical hammer end of the hammer head is made of alloyed high-chromium cast iron by lost foam casting. The mass fraction of the chemical composition of the alloyed high-chromium cast iron is: C 3.14 %, Si 0.60%, S 0.035%, P 0.05%, Mn 1.115%, Cu 0.53%, Cr 20.305%, MO 0.475%, V 0.165%, W 0.58%, RE 0.10%, B 0.083%, Fe 72.822%; Among them, the hammer handle of the hammer head is made of a finished round steel material with a steel number of 45 and a diameter of 80 mm by gold machining and cutting.

[0029] The manufacturing method of the hammer head of the present invention is as follows: the manufacturing method includes the manufacturing process of the hammer handle and the production process of the spherical hammer end alloy high-chromium cast iron, the lost foam casting process, the heat treatment process and the assembly process of the spherical hammer end and th...

Embodiment 3

[0035] Example 3: The spherical hammer head of a combined crusher with a ball diameter of 190 mm is produced. The spherical hammer end of the hammer head is made of alloy high-chromium cast iron by lost foam casting. The mass fraction of the chemical composition of the alloy high-chromium cast iron is: C 3.26 %, Si 0.69%, S 0.04%, P 0.06%, Mn 1.32%, Cu 0.61%, Cr 21.36%, MO 0.53%, V 0.19%, W 0.65%, RE 0.12%, B 0.093%, Fe 71.077%; Among them, the hammer handle of the hammer head is made of a finished round steel material with a steel number of 45 and a diameter of 90 mm through a gold machining cutting method.

[0036] The manufacturing method of the hammer head of the present invention is as follows: the manufacturing method includes the manufacturing process of the hammer handle and the production process of the spherical hammer end alloy high-chromium cast iron, the lost foam casting process, the heat treatment process and the assembly process of the spherical hammer end and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com