Heat exchanger with micro-channel, parallel-flow and all-aluminum flat pipe welding structure and application

A heat exchanger and micro-channel technology, applied in all-aluminum flat tube welded structure heat exchanger and application, micro-channel, parallel flow field, can solve the problems of large refrigerant flow resistance, large amount of refrigerant, easy corrosion, etc. Achieve the effect of compact product structure, high manufacturing reliability, and withstand voltage requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

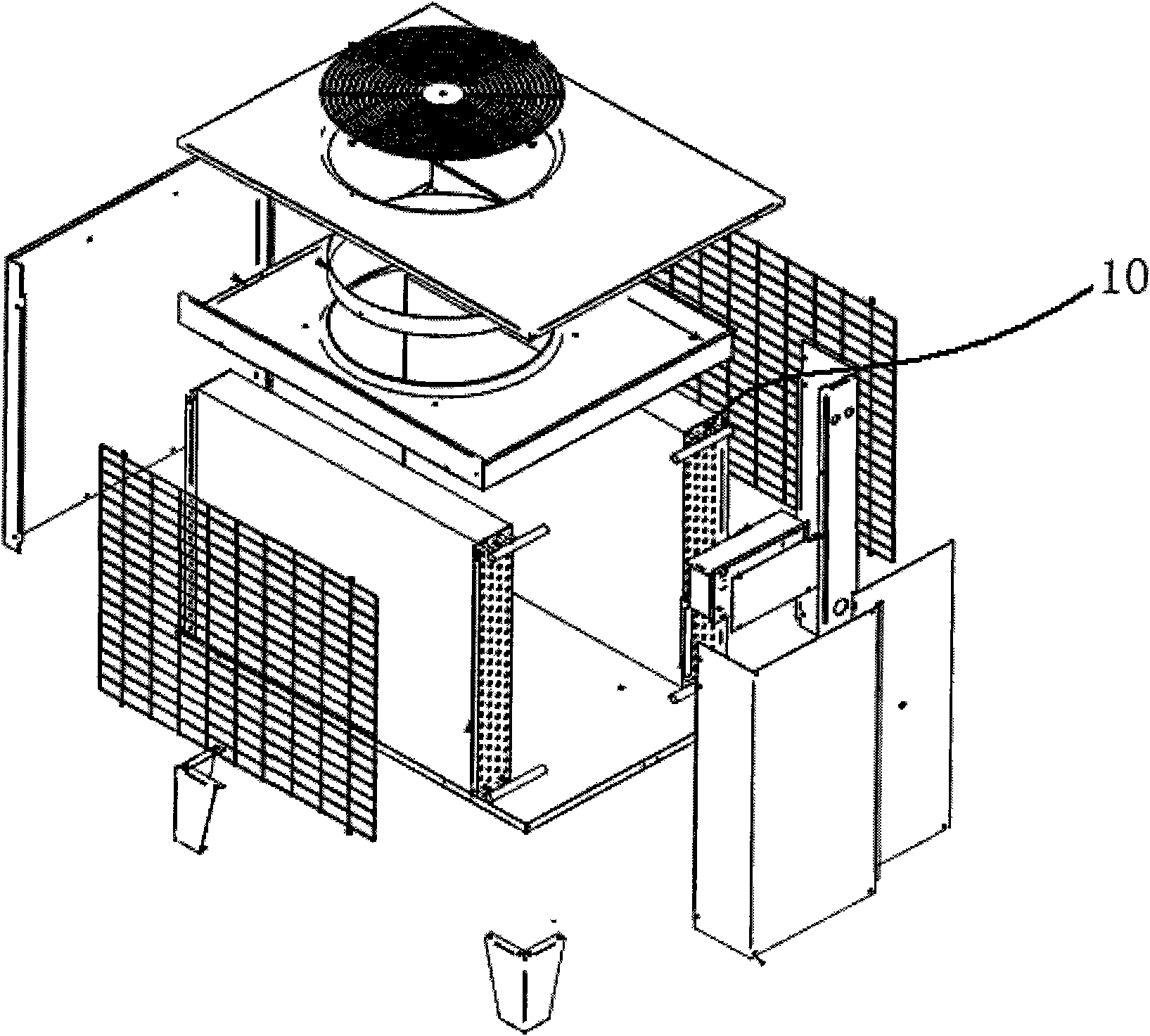

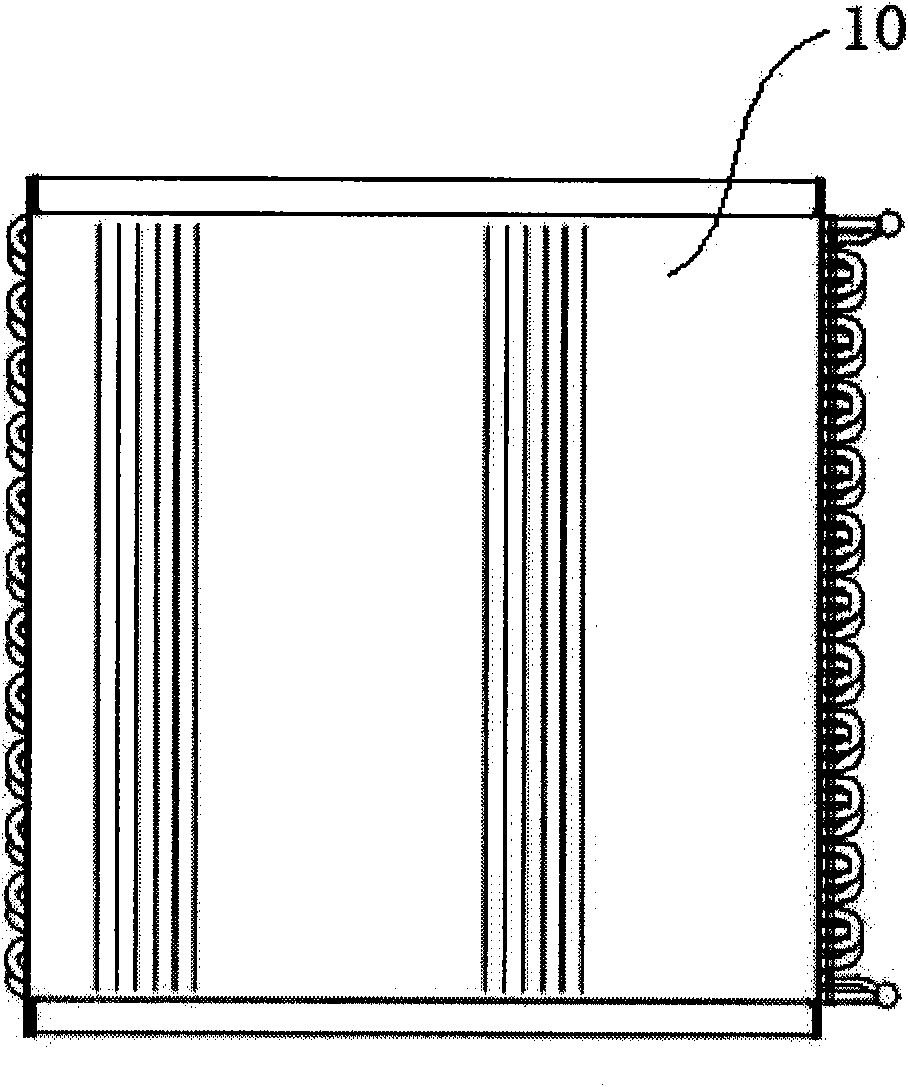

[0111] The micro-channel, parallel-flow, all-aluminum flat-tube welded structure heat exchanger in this embodiment is a double-circuit single-row parallel-flow heat exchanger, which is used as a heat pump type indoor heat exchanger for heating. see Image 6 , the heat exchanger includes a first header 100, a second header 200 and several flat tubes 300 connected between the first header 100 and the second header 200, the flat tubes 300 are extruded from aluminum It is made of pressed thin-walled profiles, and the thickness of the flat tube 300 is 1.3mm-1.6mm.

[0112] In this embodiment, several flat tubes 300 are vertically spaced in a row in a parallel manner, the first header 100 is located at the top of the entire heat exchanger, the second header 200 is at the bottom of the entire heat exchanger, and the heat exchange medium The inlet port 400 is located at the left end of the first header 100 , and the outlet port 500 is located at the right end of the first header 100 ...

Embodiment 2

[0114] The micro-channel, parallel-flow, all-aluminum flat-tube welded structure heat exchanger in this embodiment is a double-circuit single-row parallel-flow heat exchanger, which is used as a heat pump type indoor heat exchanger for refrigeration. see Figure 7 , the structure is the same as that of Embodiment 1, except that the positions of the inlet end 400 and the outlet end 500 of the heat exchange medium are different. In this embodiment, the inlet end 400 of the heat exchange medium is located at the right end of the first header 100, and the outlet end 500 is located at the left end of the first header 100 .

[0115] The working principle of this embodiment is: the heat exchange medium, such as heating agent, enters from the inlet port 400 at the right end of the first header 100, and flows vertically downward through the flat tube of the second circuit 620 to the second header 200. The side on which the throttle orifice 700 is installed flows to the side of the sec...

Embodiment 3

[0117] The micro-channel, parallel flow, all-aluminum flat tube welded structure heat exchanger in this embodiment is a single-row parallel flow heat exchanger with three circuits, and its refrigerant flow direction is designed to be used as a heat pump type indoor heat exchanger for heating . see Figure 8 , the heat exchanger includes a first header 100, a second header 200 and several flat tubes 300 connected between the first header 100 and the second header 200, the flat tubes 300 are extruded from aluminum It is made of pressed thin-walled profiles, and the thickness of the flat tube 300 is 1.3mm-1.6mm.

[0118] In this embodiment, several flat tubes 300 are vertically spaced in a row in a parallel manner, the first header 100 is located at the top of the entire heat exchanger, the second header 200 is at the bottom of the entire heat exchanger, and the heat exchange medium The inlet port 400 is located at the left end of the first header 100, the outlet port 500 is lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com