Engine mounting heat-resisting material and preparation method thereof

A technology of engine mounts and heat-resistant materials, applied in the field of modified rubber parts, can solve the problems of high heat resistance and durability of engine mounts, and achieve the effects of improving NVH performance, increasing vulcanization speed, and improving heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

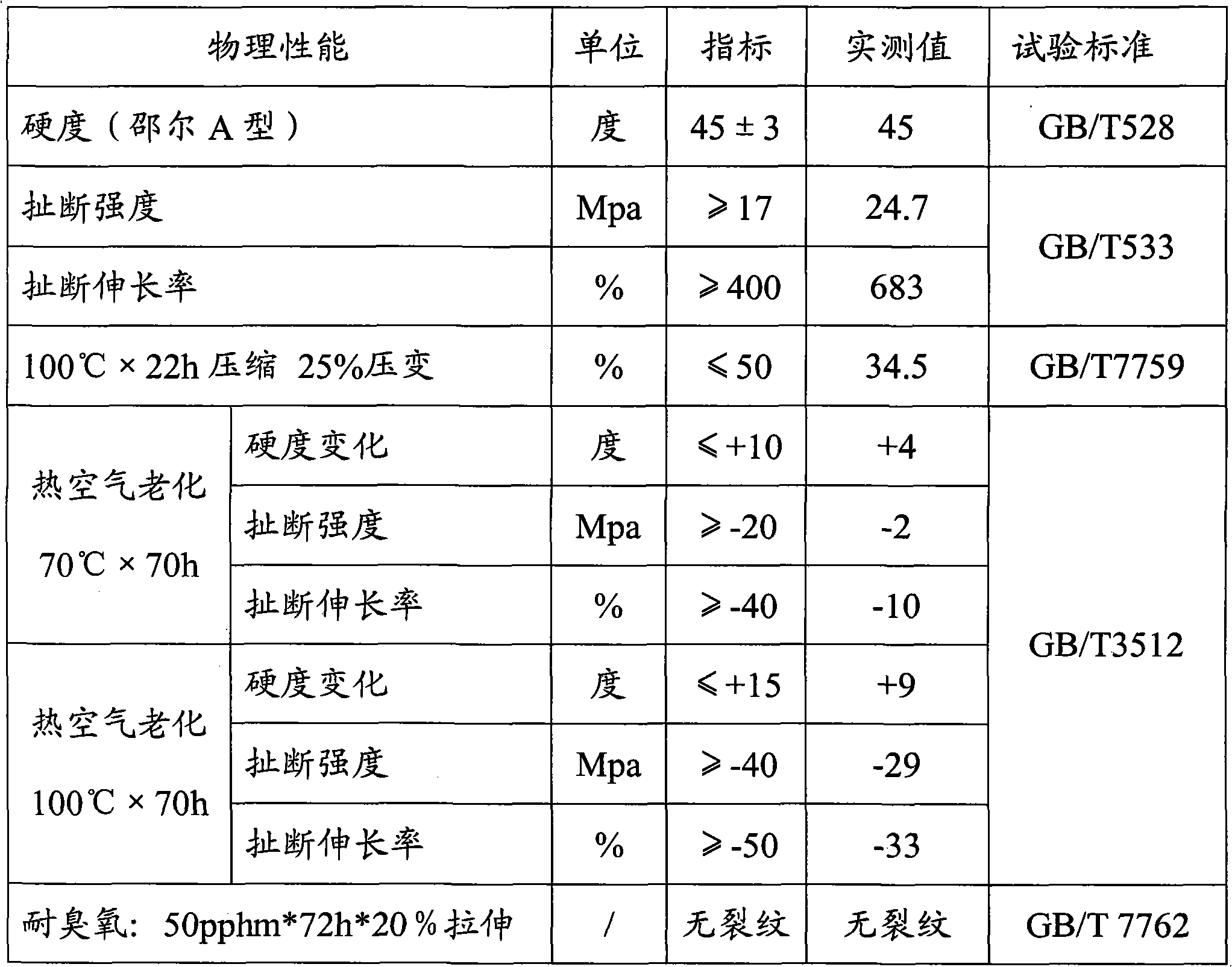

Image

Examples

Embodiment 1

[0028] Prepare according to the following recipe:

[0029] Standard natural rubber (SMR5#): 80 parts, butadiene rubber (BR9000): 20 parts, zinc oxide: 5 parts, stearic acid: 1 part, 2,2,4-trimethyl-1,2-dihydrogenation Quinoline polymer (antiaging agent RD): 1 part, N-isopropyl-N-phenyl-p-phenylenediamine (4010NA): 2 parts, compound paraffin (L5880): 3 parts, carbon black (N-774) : 35 parts, complex soap salt (NB76): 3 parts, precipitated white carbon black (175GR): 5 parts, silane coupling agent (Logsil 4C): 1 part, sulfur (S-80): 1 part, diethyl Zinc dithiocarbamate: 1 part; N-cyclohexyl-2-benzothiazole sulfenamide: 2 parts.

[0030] One-stage mixing: put standard natural rubber (SMR5#) and butadiene rubber (BR9000) in an internal mixer and knead for 25 seconds to mix the two rubbers evenly; then add zinc oxide, stearic acid, 2, 2, 4 - Trimethyl-1,2-dihydroquinoline polymer (antiaging agent RD), N-isopropyl-N-phenyl-p-phenylenediamine (4010NA), complex paraffin (L5880) and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com