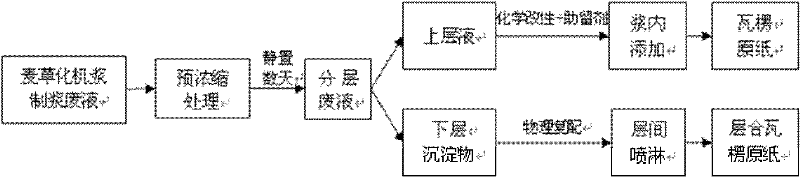

Recycle method of pulping effluent of wheat straw chemi-mechanical pulp

A technology for pulping waste liquid and recycling, applied in chemical instruments and methods, non-fibrous pulp addition, water/sludge/sewage treatment, etc., can solve the problems of high application cost and poor operability, and achieve strong pertinence , the effect of less investment and broad development prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] (1) pre-concentrating the waste liquid of wheat straw chemical pulping, after concentration, the mass concentration is 10%, and standing for several days until the upper and lower layers;

[0020] (2) Take the clarified liquid from the upper layer, adjust the pH to 9, then, stir it electrically in a water bath at 25°C for 5 minutes, then raise the temperature of the water bath to 60°C, and add the mixture of formaldehyde and potassium persulfate within 1 hour , stirring and reacting for 7 hours, and finally, adding hydrochloric acid to adjust the pH to be neutral, wherein the clarified liquid in the upper layer: formaldehyde: the mass ratio of potassium persulfate is 100:20:8;

[0021] (3) Add aluminum chloride to OCC (Old Corrugated Containers) waste paper pulp to decompose for 3 minutes, then add the modified waste liquid obtained in step (2) to decompose for 5 minutes, and finally make corrugated base paper, wherein aluminum chloride The addition amount accounts for ...

Embodiment 2

[0024] (1) Pre-concentrating the pulping waste liquid of wheat straw chemical pulping, the mass concentration is 15%, and standing for several days until the upper and lower layers;

[0025] (2) Take the clarified liquid from the upper layer, adjust the pH to 13, then, stir it electrically in a water bath at 45°C for 10 minutes, then increase the temperature of the water bath to 70°C, and add glyceryl trimethyl chloride within 1 hour The mixed solution of ammonium chloride and sodium hydroxide was stirred and reacted for 4 hours, and finally, adding acetic acid solution to adjust the pH to be neutral, wherein, the clarified liquid of the upper layer: the mass ratio of glyceryl trimethylammonium chloride: sodium hydroxide 100:25:5;

[0026] (5) Add aluminum sulfate to OCC (Old Corrugated Containers) waste paper pulp to decompose for 5 minutes, then add the modified waste liquid obtained in step (2) to decompose for 5 minutes, and make corrugated base paper, wherein the amount o...

Embodiment 3

[0029] (1) Carry out pre-concentration treatment on the pulping waste liquor of wheat straw chemical pulping, the mass concentration is 30%, and let it stand for several days until it is layered up and down;

[0030] (2) Take the clarified liquid of the upper layer, adjust the pH to 10, then, stir electrically in a water bath at 30°C for 20 minutes, then raise the temperature of the water bath to 80°C, and add maleic anhydride and ammonium persulfate within 1 hour. The mixed solution was stirred and reacted for 5 hours, and finally, a sulfuric acid solution was added to adjust the pH to be neutral, wherein the clarified liquid of the upper layer: maleic anhydride: the mass ratio of ammonium persulfate was 100:40:10;

[0031] (7) Add cationic starch to OCC (Old Corrugated Containers) waste paper pulp to decompose for 5 minutes, then add the modified waste liquid obtained in step (2) to decompose for 3 minutes, and make corrugated base paper. It accounts for 1.2% of the mass of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com