Method for improving material blood compatibility by using electrostatic self-assembled coating

A blood-compatibility, electrostatic self-assembly technology, applied in the field of surface science and biomedical polymer materials, can solve the problems of difficult to obtain phosphorylcholine-rich surface, limited biocompatibility, limited application, etc. To achieve the effect of reducing platelet adhesion, improving blood compatibility, and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 0.5 g of chitosan was dissolved in 100 mL of 1% acetic acid aqueous solution, and stirred at room temperature for 24 hours. After the chitosan is dissolved, filter it with a sand-core funnel and let it stand for 30 minutes to eliminate air bubbles. After the air bubbles were eliminated, the chitosan film was coated on the glass slide by dip coating, and left to air at room temperature for 24 hours. After the chitosan film is dried, soak it in 0.1% sodium hydroxide solution for 1 hour, then soak it with distilled water, change the distilled water every 4-5 hours, and soak for 48 hours in total. Finally, vacuum-dry at 30°C for 8 hours to obtain a chitosan film.

Embodiment 2

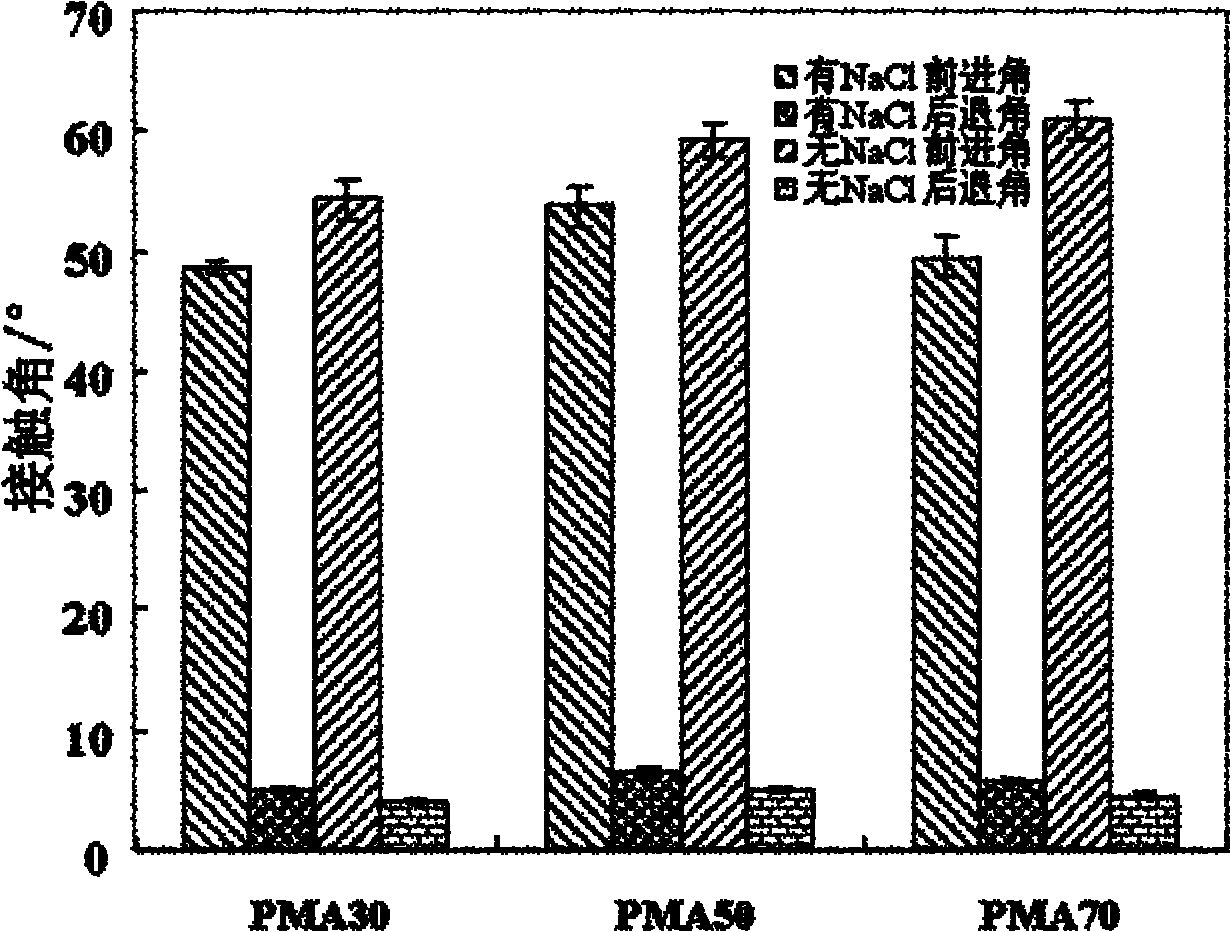

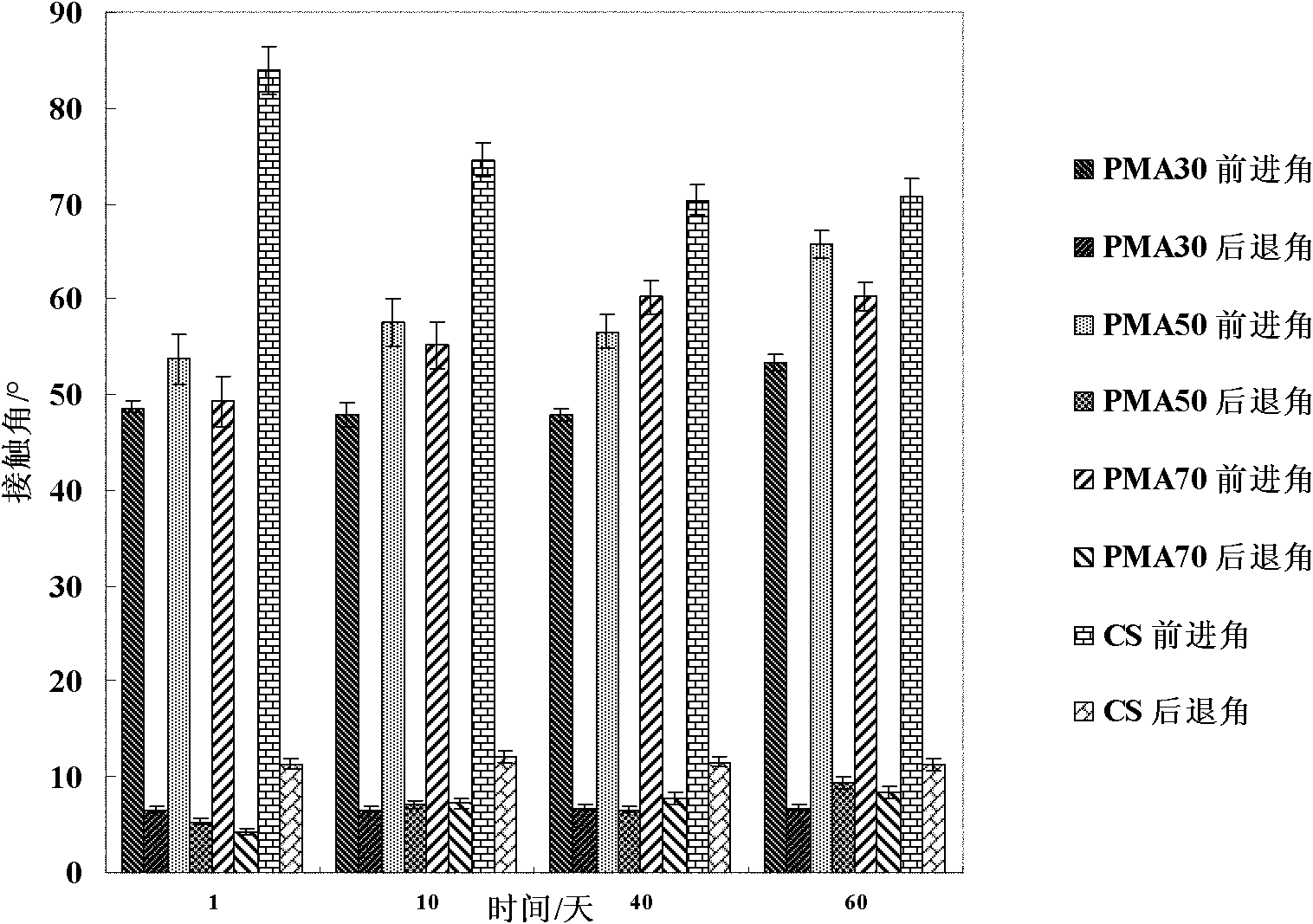

[0028] Get the chitosan film that above-mentioned method prepares, be soaked in 20mL, in 1mg / mL PMA30, PMA50, PMA70 aqueous solution (30,50,70 represent respectively the percent mole percent of monomer MPC feeding in polymer synthesis and account for total throwing monomer content), adsorbed for 15min, then rinsed with distilled water, and freeze-dried to obtain a modified chitosan film. Compared with the chitosan membrane, the advancing angle of the modified membrane in contact with water was reduced by about 20 degrees.

Embodiment 3

[0030] Take the chitosan film prepared by the above method, soak it in 20mL, 1mg / mL PMA30, 0.14M NaCl aqueous solution, absorb for 15min, rinse with 0.14M NaCl aqueous solution and distilled water successively, and freeze-dry to obtain the modified chitosan membrane. sugar film. Compared with the chitosan membrane, the modified membrane significantly reduced the amount of protein adsorption, platelets did not aggregate and had only a small amount of adhesion, and the blood compatibility was significantly improved ( figure 1 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com