Time sequence model and method for predicting multi-phase mixing uniformity

A time-series model and multi-phase mixing technology, applied in the field of chemical engineering, can solve problems such as time-consuming, labor-intensive, low-cost, inability to detect and avoid abnormal operations, and achieve the effects of avoiding danger, avoiding accidents, and high practical value

Inactive Publication Date: 2010-12-29

KUNMING UNIV OF SCI & TECH

View PDF1 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the experimental verification of the whole process is time-consuming, laborious, and low-cost, and it cannot detect and avoid abnormal operations, or even avoid accidents.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

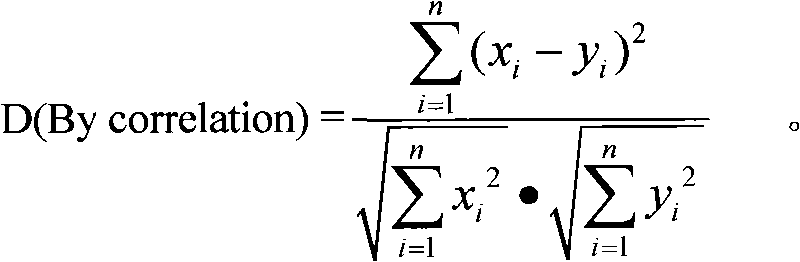

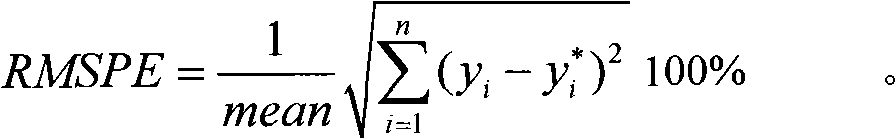

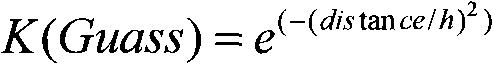

The invention discloses a method for establishing a time sequence model for predicting multi-phase mixing uniformity, and is mainly applicable to predicting fluid mixing effect and theoretically guiding and correcting experiment design in a chemical engineering experiment. The method particularly comprises the following steps of: (1) acquiring a multi-phase real-time stirring and mixing pattern by using electron tomography or a high-speed camera; (2) calculating the zeroth-dimension betti number of the acquired real-time pattern by using a written program; (3) acquiring related data at the beginning every certain time by using the method of the step (2) so as to obtain a corresponding time sequence; (4) calculating time delay variable, embedded dimension and bandwidth by a phase reconstruction method by using the time sequence obtained in the step (3); (5) linearly predicting the time sequence in the step (3) by using a one-step forward method and local weighting so as to obtain the complete time sequence; and (6) verifying prediction error by using an experimental method. The model is applied to the prediction of the mixing effect of all fluid; and the method has the advantages of simplicity, convenience and extremely high practical value.

Description

technical field The invention belongs to the technical field of chemical engineering, in particular to a method for predicting the mixing uniformity of all fluids in the chemical industry. Background technique Time series analysis is the theory and method of establishing mathematical models through curve fitting and parameter estimation based on time series data obtained from systematic observation. It is generally performed using curve fitting and parameter estimation methods such as nonlinear least squares. Time series analysis is commonly used in national economic macro control, regional comprehensive development planning, enterprise management, market potential forecasting, weather forecasting, hydrological forecasting, earthquake precursor forecasting, crop disease and pest disaster forecasting, environmental pollution control, ecological balance, astronomy and oceanography study etc. The basic steps of time series modeling are: ① Obtain the time series dynamic data o...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01N33/00

Inventor 王华范国锋徐建新王仕博朱道飞

Owner KUNMING UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com