Stone paper blowing production equipment

A technology of production equipment and film blowing method, applied in the direction of inorganic fibers/sheets, etc., can solve the problems of heavy weight, inability to cool, large specific heat capacity, etc., and achieve the effect of improved mechanical properties and obvious effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

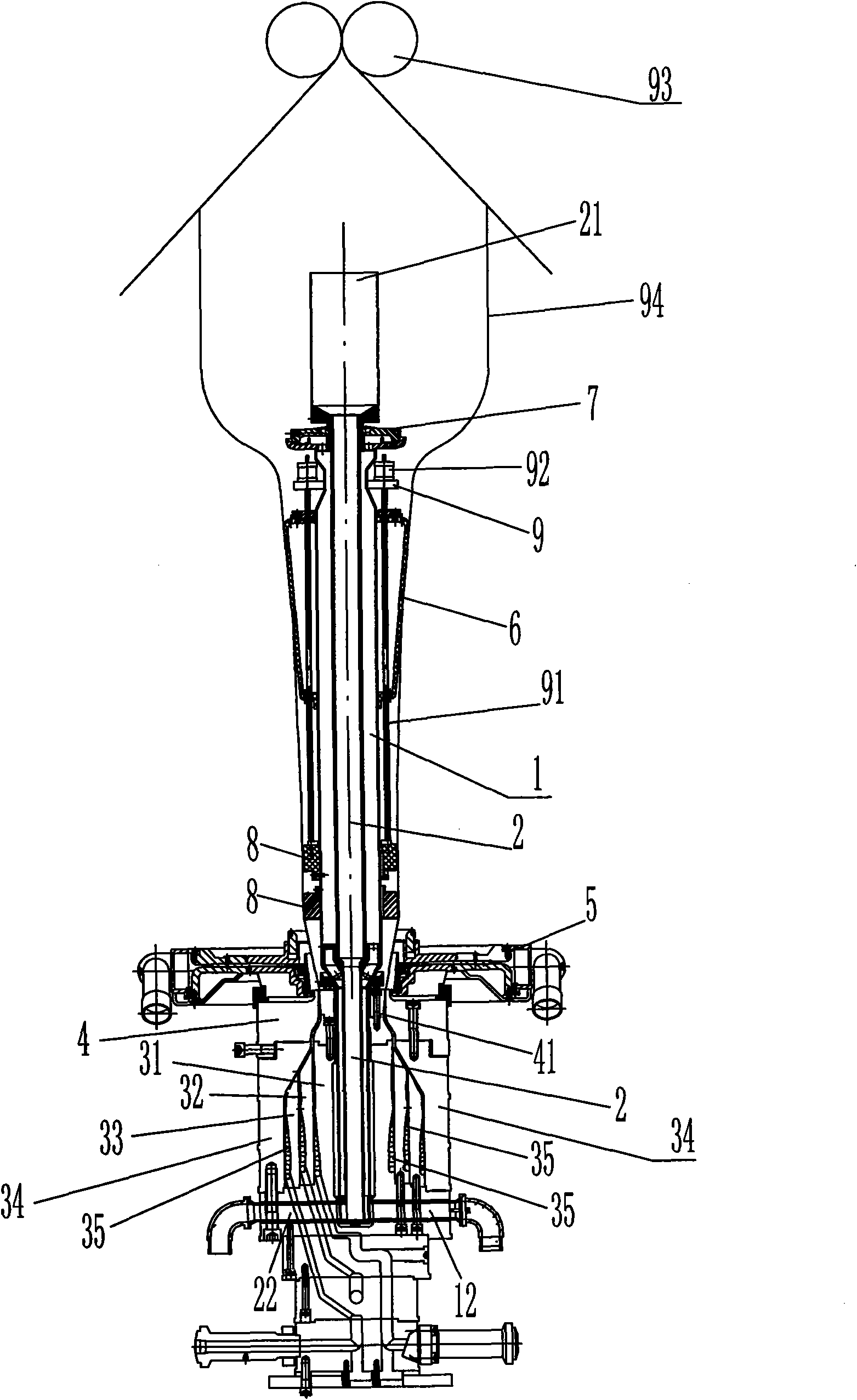

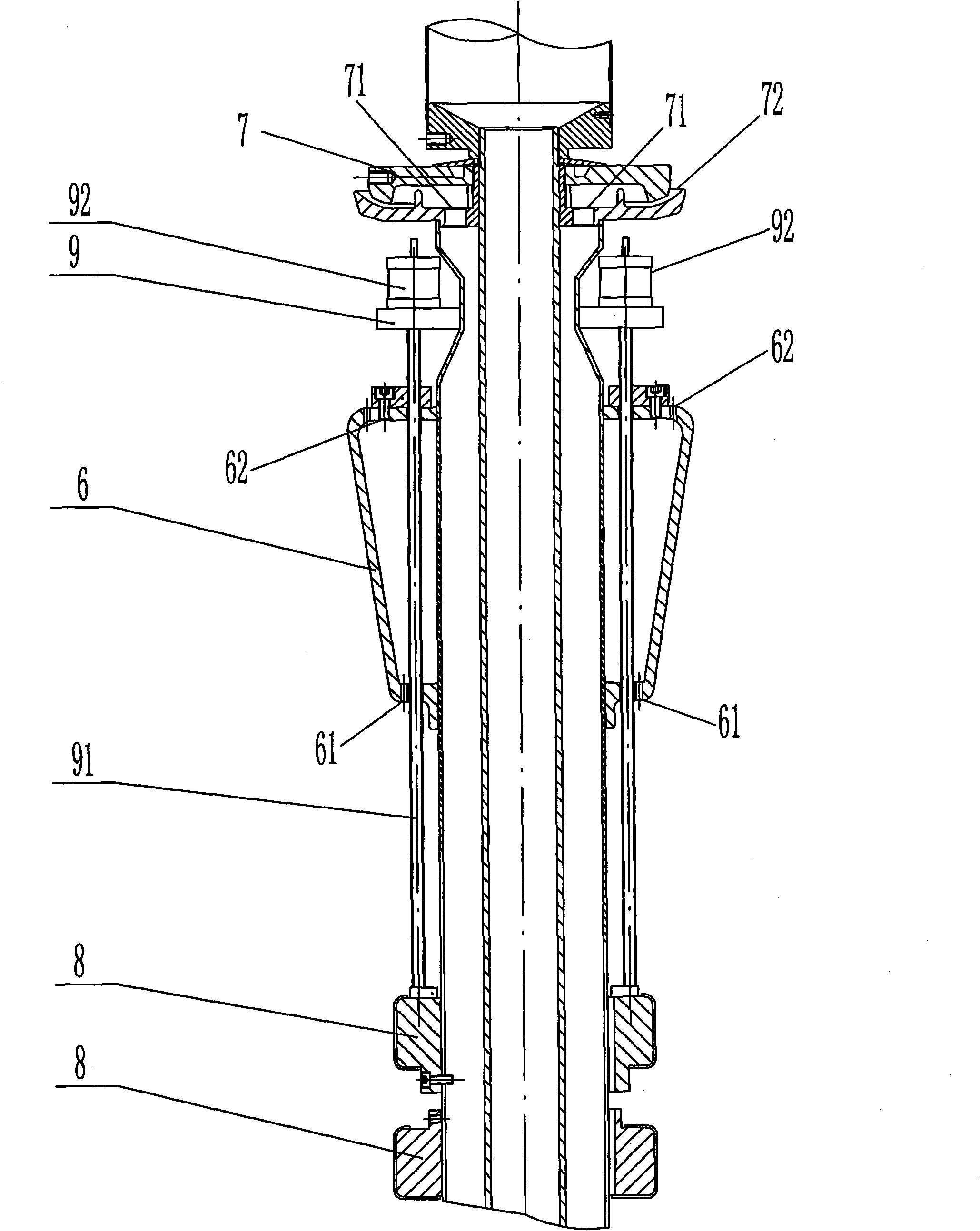

[0024] figure 1 , figure 2 , image 3 The stone paper blown film production equipment shown comprises machine head, and machine head is provided with screw sleeve and mouth die 4, and screw sleeve comprises mold core body 31, middle rotating core 32, outer rotating core 33, and outer rotating core 33 is also provided with There is a mold shell 34; the die 4 is located on the spiral sleeve, the core body 31, the middle rotating core 32, and the outer rotating core 33 are respectively provided with a spiral flow channel 35, and the die 4 is provided with a circular extrusion port 41. There is an outer cooling air ring 5, and the central position of the machine head is provided with a central air inlet straight pipe 1 and a central exhaust air pipe 2, and the central air inlet straight pipe 1 is set outside the central air exhaust straight pipe 2; the central air inlet straight pipe 1 It is connected with an air inlet duct 12, the outer end of the air inlet duct 12 is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com