Cr-containing steel for wire line core drilling and manufacturing method thereof

A rope coring and manufacturing method technology, which is applied in the direction of earth cube drilling and extracting undisturbed core devices, etc., can solve the problems of no clear and unique regulations on materials and heat treatment systems, and achieve resistance to cracks, delayed cracking, normal temperature mechanical properties, and metallographic structure The effect of stability and strong mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-8

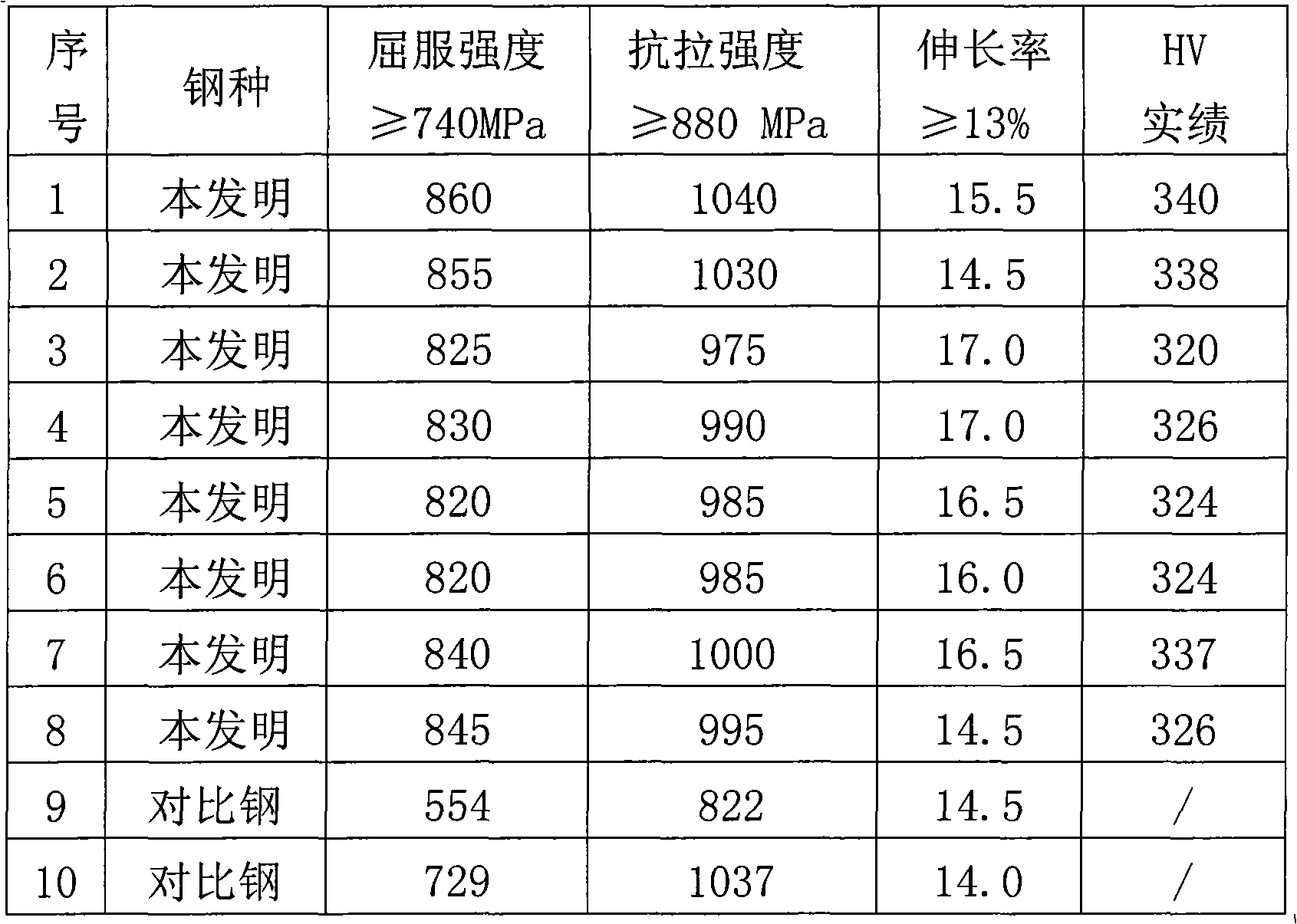

[0043] Below 1 # ~8 # It is the steel type of the present invention and 9 # 、10 # Imported steel pipes are compared in terms of chemical composition and mechanical properties. The chemical composition is shown in Table 2, the production process is shown in Table 3, and the mechanical properties are shown in Table 4.

[0044] Table 4 mechanical properties

[0045]

[0046] In summary, the yield strength of the steel pipe manufactured according to the method of the present invention is greater than 740MPa, the tensile strength is greater than 880MPa, and the elongation is greater than 13%, and the performance meets the requirements of DZ75 steel grade. At the same time, it also has the performance of resisting delayed cracking of cracks, stable mechanical properties at room temperature, and its comprehensive performance can compete with imported products of the same level, so the invention has good promotion and application prospects.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com