Supercritical water oxidation treatment method for high-concentration organic wastewater

A supercritical water oxidation and treatment method technology, applied in the direction of water/sewage multi-stage treatment, degassed water/sewage treatment, oxidized water/sewage treatment, etc. High energy consumption and other problems, to achieve the effect of short reaction time, high processing efficiency, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The laboratory prepared phenol-containing wastewater, and its main components are shown in Table 1.

[0031] Table 1

[0032] main ingredient

content

COD

32740mg / L

TOC

11502mg / L

Phenol concentration

15g / L

58.8mg / L

Cl-concentration

20.2mg / L

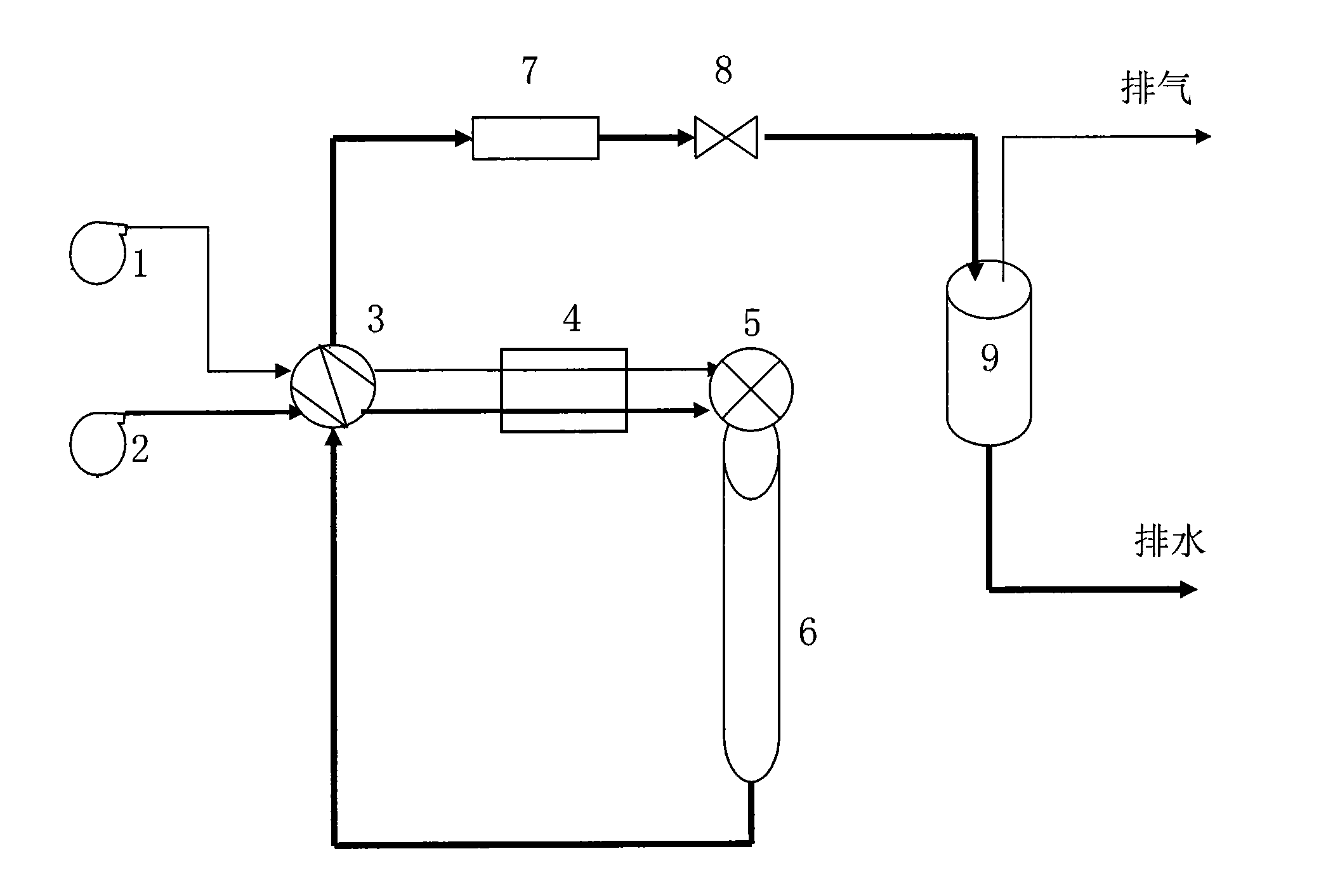

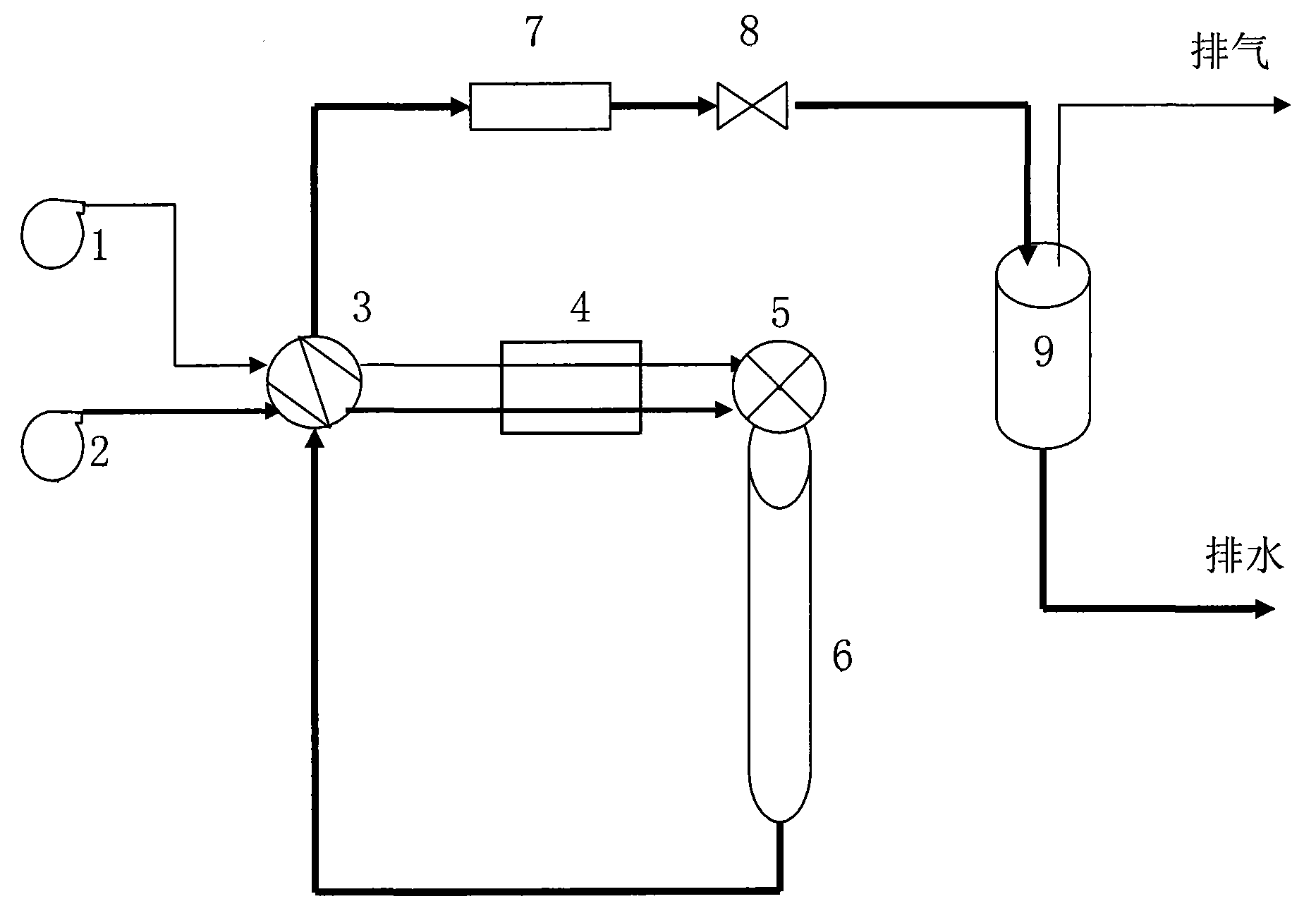

[0033] The prepared phenol-containing wastewater and the hydrogen peroxide with hydrogen peroxide as an oxidant are first pressurized to 40MPa through high-pressure pumps 1 and 2, and then enter the heat exchanger 3 respectively; 1.1 times the amount (mol).

[0034] After heat exchange, the hydrogen peroxide and phenol-containing wastewater enter the preheater 4, and the temperature rises to 400°C; then the hydrogen peroxide and phenol-containing wastewater are mixed in the mixer 5, and the mixing residence time is 1 second.

[0035] The mixed phenol-containing wastewater enters the reactor 6, which is a double-pipe reactor, and its reaction tu...

Embodiment 2

[0038] The laboratory prepares waste water containing cyclohexane formic acid, and its main components are shown in Table 2.

[0039] Table 2

[0040] main ingredient

content

COD

31250mg / L

TOC

9656mg / L

Cyclohexanecarboxylic acid concentration

15g / L

102.5mg / L

Cl - concentration

44.6mg / L

[0041] Contain cyclohexane formic acid waste water and the hydrogen peroxide with hydrogen peroxide as oxygenant, at first pressurize to 25MPa, then enter heat exchanger 3 respectively; The amount (mol) of hydrogen peroxide is the complete oxidation theoretical oxygen demand ( Mole) 1.3 times.

[0042] After heat exchange, the hydrogen peroxide and wastewater containing cyclohexane formic acid enter the preheater 4, and the temperature rises to 450°C; then the hydrogen peroxide and phenol wastewater are mixed in the mixer 5, and the mixing residence time is 5 seconds.

[0043] The mixed waste water contai...

Embodiment 3

[0046] The laboratory prepared waste water containing p-aminobenzenesulfonic acid, the main components of which are shown in Table 3,

[0047] table 3

[0048] main ingredient

content

COD

31020mg / L

[0049] TOC

9538mg / L

Concentration of sulfanilic acid

25g / L

320.8mg / L

Cl - concentration

89.5mg / L

[0050] The amount (mole) of hydrogen peroxide is 1.4 times of the theoretical oxygen demand (mole) of complete oxidation of organic matter in waste water containing p-aminobenzenesulfonic acid; the reaction temperature of supercritical water oxidation reaction is 600 ℃, reaction pressure is 25MPa, reaction time is 50 second, other operating parameters and process and processing equipment are the same as in Embodiment 1.

[0051] The TOC removal rate of this treatment process reaches over 99%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com