Lithium ion battery

A lithium-ion battery and electrolyte technology, which is applied in the direction of battery electrodes, secondary batteries, battery pack components, etc., can solve the problem of large loss in the first charge and discharge efficiency and capacity of lithium-ion batteries, and it is difficult to balance the safety performance and battery life of lithium-ion batteries. Chemical properties and other issues, to achieve the effects of charging and discharging efficiency and capacity, good electrochemical performance, and good safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0037] Preparation of the electrolyte: the electrolyte is lithium hexafluorophosphate (LiPF 6 ) is lithium salt, with the mixture of ethylene carbonate (EC), ethyl methyl carbonate (EMC) and dimethyl carbonate (DMC) as solvent, the weight ratio of EC, EMC, DMC is EC: EMC: DMC=5: 2:3. In addition, 10% by weight of dimethyl methylphosphonate (DMMP) was added into the electrolyte.

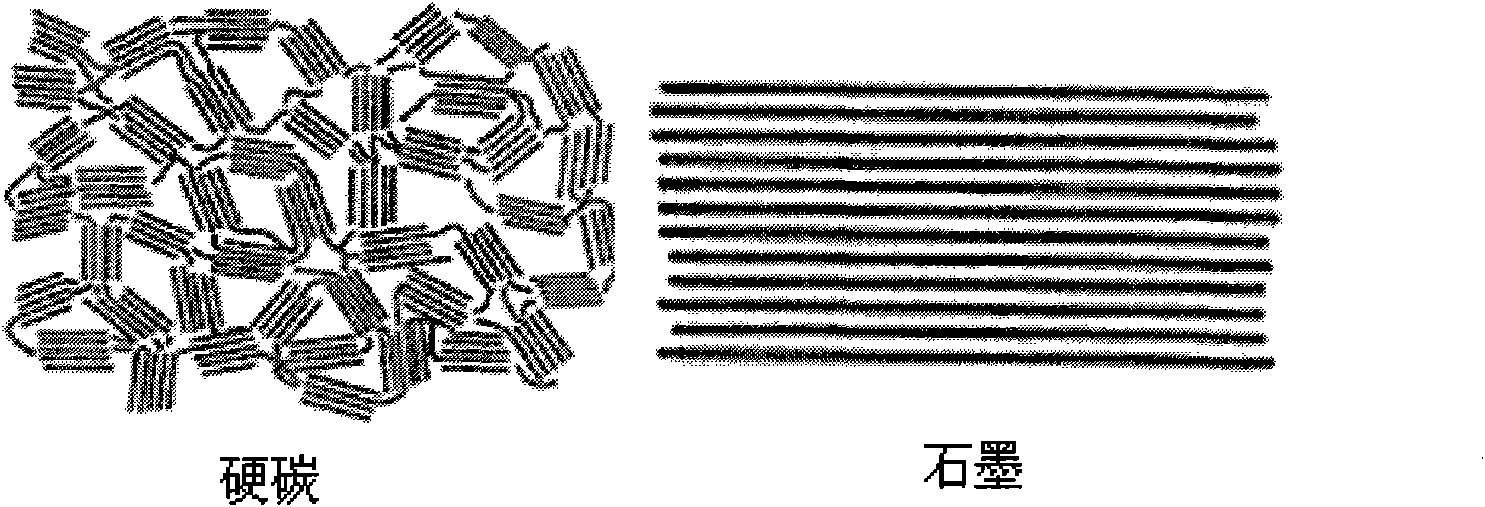

[0038] The preparation of negative plate: with hard carbon as negative active material, it accounts for 86% of negative electrode diaphragm gross weight; With styrene-butadiene rubber (SBR) as binding agent, it accounts for 6% of positive electrode diaphragm gross weight; With carbon powder (Super-p) is used as a conductive agent, which accounts for 8% of the total weight of the negative electrode membrane. The above powder was mixed and stirred evenly in deionized water to make negative electrode slurry. The negative electrode slurry was uniformly coated on a copper foil with a thickness of 22 μm ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com